rhncue said:

A number of things here. First, the larger the object in diameter the slower you can run it. As the radius is increased the speed is squared I believe. For an example, something with a 1/2" radius going at 20,000 rpm may have a surface speed of 100 mph. Now you double the radius to an inch an the surface speed now is 400 mph. At a certain speed and weight, centrifugal force will be to much for the spinning object and it will fly apart. This is the reason larger router bits for cabinet making must be run so much slower. I would imagine you could have a router bit made with a larger number of cutting edges still on a small circumference that would be quicker. It's the cuts per minute that you are looking for.

2. Sorry, If I said the blade was running at 250,000 rpm I misspoke. what I meant to say was 250,000 cpm. The table saw is running at 3450 rpm. 3450X72 teeth equals 248,400 cuts per minute.

Dick

Just picking nits here: doubling the radius only doubles the surface speed. I suspect you are confusing the relationship between diameter & area. If you double the diameter, the area increases by a factor of 4. If you triple the diameter, the area increases by a factor of 9.

And just to satisfy my curiousity, I did the math and a 1/2" diameter cutter @ 20,000 rpm has a surface speed of only 29.75 mph. The surface of a 1" diameter cutter @ 20K rpm is moving at 59.5 mph.

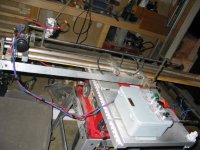

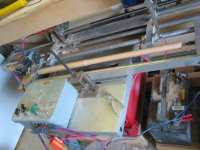

Your idea that more teeth on a given diameter would cut smoother is absolutely correct. The first cutter I made for machining tenon threads was a 2 fluter made from a 3/4" router bit. It worked but there was room for improvement. The next was made from a 6 flute 3/4" reamer and it worked much better. The final design has 10 teeth in carbide (at the same 3/4" diameter) & it cuts beautiful external threads.

There are 3 other factors to consider here, too. The speed at which the object being cut is rotating makes a difference, as does the feed rate. Assuming identical feed rates, Machine A, cutting at 250K cpm on an shaft rotating at 100 rpm, will have 2X the chip load than that of a shaft rotating at 200 rpm.

Theoretically, the faster the shaft turns, the smoother the cut. Theoretically.

Or...theoretically, if you double the shaft speed, you can also double the feed rate to achieve the same chip load you had with the slower setup.

Again, this is all theoretical. The 3rd factor that arises when such high speeds & cpm & a long, thin shaft are thrown together is harmonics. If something is the least bit out of balance or the wood is harder on one side or a few teeth are duller than the others, a vibration can occur that ruins all your efforts. The easiest solution is to slow things down a bit & be patient.

Whew. Sorry. Bob got carried away here. Does my mid afternoon boredom show? Back to the shop.