Can someone here tell me a few things....

1. What IS a sharp point?

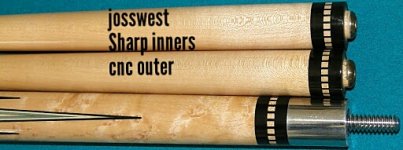

2. How can you tell a CNC point from handmade or any other way, for that matter, by looking at the cue?

3. Can comparison pictures be posted showing the differences between the two?

4. I am trying to treat myself to a new, higher end cue. I currently have Joss, Cuetec, Players and McDermott and I would like to purchase something awesome, semi-handmade but it is becoming evident I do not know what I am looking at!

Thanks

1. What IS a sharp point?

2. How can you tell a CNC point from handmade or any other way, for that matter, by looking at the cue?

3. Can comparison pictures be posted showing the differences between the two?

4. I am trying to treat myself to a new, higher end cue. I currently have Joss, Cuetec, Players and McDermott and I would like to purchase something awesome, semi-handmade but it is becoming evident I do not know what I am looking at!

Thanks