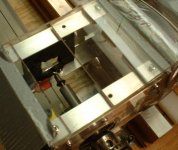

What are some of the things that people are doing to contain their sawdust and chips. I made use of some .25 plexie glass the someone was throwing away! I am going to put a lid on it and cut 2-2" holes through the bottom and about 4 inches away from either end and conect my dust collection system to it.

Oops forgot Pics!

Oops forgot Pics!