This last picture is of a 1912 Brunswick Regina 5'×10' billiards table slate, using only 4 slate screws to mount it.

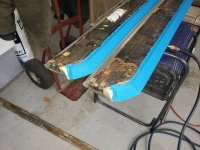

The first picture is showing a few of 5 pieces of slate for it, no slate screws were used at all to mount those slates.

The first picture is showing a few of 5 pieces of slate for it, no slate screws were used at all to mount those slates.