asiasdad

Banned

So I'm waiting on RKC to take a nomadic adventure to South Texas

to set up my humble little 55 year old pre Gold Crown Sport King. As

I have some experience with table mechanics in the PNW where RKC

calls home (when he's not in his truck,) I have learned to do as much as

I can myself so the critical work I cannot do will have the mechanics

undivided attention.

This is intended to be a primer to assist those of you who are willing

to wait for a quality table mechanic in such the same manner as you

would wait for a quality cue maker to spin a few chunks of wood

on a lathe get the maximum value from their time:

View attachment frame_alignment.BMP

Know exactly where you want your table. I know how irritating it is

when I move and my woman has no clue where she wants the damn sofa.

Once you know precisely where you want the table, take some of that

blue painters tape and map out an outline. In this case,

I mapped out a 10' x 5' rectangle perfectly centered in the area I had

available to handle a 9' table without having any "house hazard" preventing

full cue stroke from any angle around the table. I am fortunate that my

available space is a 22 X 18 area.

Once I started building the framework, I then measured where the legs

would be centered, and put some alignment tape down in the event of

table shifting from bumping it while putting it together.

View attachment base_set_up.BMP

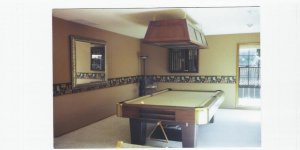

Now I have the frame built and the slate mocked up close to where it

will be when Glen is done gluing it together. What matters most here

is that the center pockets are centered where you want them. In my

house I have a center ceiling beam that pretty much tells me where

center is located, so thats where it went.

Placing the slate on the frame was not so much to save Glen any

nut ache as it was to create a solid base where I put a work bench

on the slate, then placed that big 7' light on the workbench, and had

a much easier time hanging it off the ceiling beams.

I'm quite proud of the way I got that big ba$tard up there being only

1/4" off level on the first try With the table being perfectly centered,

With the table being perfectly centered,

it was very easy to do the same with the light.

View attachment hardware.BMP

From years of rebuilding custom motorcycles, I had long ago learned to

label everything in component groups. The time saved not looking for that

damn "_______" is well worth the time spent organizing the

hardware in the first place.

View attachment artemis_rails.BMP

Also, make certain you have everything you need for your mechanic to

put it all together. That truck ain't sitting in your driveway burning gas

for free.

View attachment slate_frame.BMP

You can also save a lot of time and money by not having a table all beat

to hell by previous table butchers. If yours has bits of cloth and staples

in the frames, its' been butchered. Pull that stuff out before your table

mechanic shows up.

Take a look at this slate frame, and you will see it's in very good shape for being 5+ decades old.

(more to follow)

to set up my humble little 55 year old pre Gold Crown Sport King. As

I have some experience with table mechanics in the PNW where RKC

calls home (when he's not in his truck,) I have learned to do as much as

I can myself so the critical work I cannot do will have the mechanics

undivided attention.

This is intended to be a primer to assist those of you who are willing

to wait for a quality table mechanic in such the same manner as you

would wait for a quality cue maker to spin a few chunks of wood

on a lathe get the maximum value from their time:

View attachment frame_alignment.BMP

Know exactly where you want your table. I know how irritating it is

when I move and my woman has no clue where she wants the damn sofa.

Once you know precisely where you want the table, take some of that

blue painters tape and map out an outline. In this case,

I mapped out a 10' x 5' rectangle perfectly centered in the area I had

available to handle a 9' table without having any "house hazard" preventing

full cue stroke from any angle around the table. I am fortunate that my

available space is a 22 X 18 area.

Once I started building the framework, I then measured where the legs

would be centered, and put some alignment tape down in the event of

table shifting from bumping it while putting it together.

View attachment base_set_up.BMP

Now I have the frame built and the slate mocked up close to where it

will be when Glen is done gluing it together. What matters most here

is that the center pockets are centered where you want them. In my

house I have a center ceiling beam that pretty much tells me where

center is located, so thats where it went.

Placing the slate on the frame was not so much to save Glen any

nut ache as it was to create a solid base where I put a work bench

on the slate, then placed that big 7' light on the workbench, and had

a much easier time hanging it off the ceiling beams.

I'm quite proud of the way I got that big ba$tard up there being only

1/4" off level on the first try

it was very easy to do the same with the light.

View attachment hardware.BMP

From years of rebuilding custom motorcycles, I had long ago learned to

label everything in component groups. The time saved not looking for that

damn "_______" is well worth the time spent organizing the

hardware in the first place.

View attachment artemis_rails.BMP

Also, make certain you have everything you need for your mechanic to

put it all together. That truck ain't sitting in your driveway burning gas

for free.

View attachment slate_frame.BMP

You can also save a lot of time and money by not having a table all beat

to hell by previous table butchers. If yours has bits of cloth and staples

in the frames, its' been butchered. Pull that stuff out before your table

mechanic shows up.

Take a look at this slate frame, and you will see it's in very good shape for being 5+ decades old.

(more to follow)

Last edited: