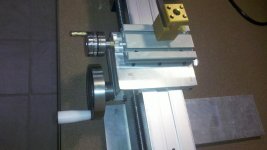

I got a new lathe this week, and I'm hoping its my own ignorance, but it just ain't workin very well. I can't get the plate where the tool post attatches to be smooth and solid. I've had 3 people try to tune it in, but it just won't work. There's either a ton of slop, or its so tight it won't hardly move left or right. Its also very jerky, like its binding up or something? Obviously, I can't use it like this for any cue work, so I just tried to make some collets out of some white delrin, and the motor kept shutting off?? Id wait for a second, and I could hear the little breaker on the power supply click, and I could use it again for maybe 30 seconds before it would trip again. Finally, it just got hot, and wouldn't trip at all, so either it burned up, or I gotta wait even longer, both of which do me no good at all. Any suggestions?

Joe

Joe