MamboFats

Active member

Goodmorning all,

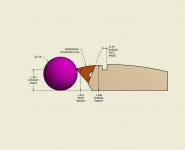

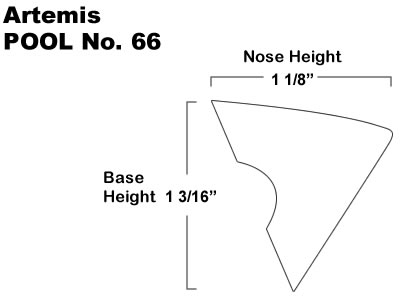

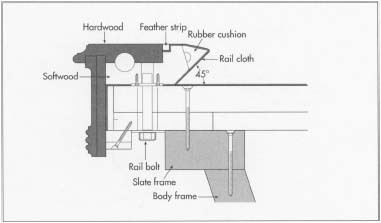

Regarding the dimensions of pool table cushions I found these graphics online.

The first shows a 20° angle for glueing the cushion, the other graphic of the ARtemis brand I imported in Fusion360 and it measures a ±23°.

The third graphic shows a 45° angle on the bottom side of the cushion (should translate to 15° on the inside rail)

Is there a good/better/best angle ?

Does it depend on manufacturer (Artemis is easily available for me) ?

Can anyone clarify this for me?

thx for your help

Alain

Regarding the dimensions of pool table cushions I found these graphics online.

The first shows a 20° angle for glueing the cushion, the other graphic of the ARtemis brand I imported in Fusion360 and it measures a ±23°.

The third graphic shows a 45° angle on the bottom side of the cushion (should translate to 15° on the inside rail)

Is there a good/better/best angle ?

Does it depend on manufacturer (Artemis is easily available for me) ?

Can anyone clarify this for me?

thx for your help

Alain