I have never owned one. The wood Joint Pins, do they stand up well? are they very durable? what do they hit like? would you prefer them over the the brass or steel or G-10?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wood Joint Pins

- Thread starter Celophanewrap

- Start date

wood pin cues

DURABILITY i build wood pin cues and carry an extra pin in my cue case. when i am ask about durability, i just take the pin out and hand it to the person with the question, and tell him to go ahead and snap it in half. no one has ever broken one.

drop a metal pin cue and let the pin hit first and you might bend the pin, with wood it gives a bit then flexes back.

i have sold hundreds of cues and never had one returned with a broken pin.

HIT is a figment of YOUR imagination, as each person's is different.

each person is different, so i will tell you my way of thinking. viberations traveling from the tip to your grip hand in a normal cue, leather tip strikes ball, viberations goes through ferrule, shaft ,joint ring, stainless joint, brass insert, steel pin, joint ring, forearm, inlays, into handle wood then a linen wrap, then into your hand.

wood pin cue, viberations travel through tip, pad, shaft, joint ring wood pin, joint ring, wood handle into your hand.

if both cues were constructed same materials with the same quality worksmanship, which do YOU think would give you the best feel?

DURABILITY i build wood pin cues and carry an extra pin in my cue case. when i am ask about durability, i just take the pin out and hand it to the person with the question, and tell him to go ahead and snap it in half. no one has ever broken one.

drop a metal pin cue and let the pin hit first and you might bend the pin, with wood it gives a bit then flexes back.

i have sold hundreds of cues and never had one returned with a broken pin.

HIT is a figment of YOUR imagination, as each person's is different.

each person is different, so i will tell you my way of thinking. viberations traveling from the tip to your grip hand in a normal cue, leather tip strikes ball, viberations goes through ferrule, shaft ,joint ring, stainless joint, brass insert, steel pin, joint ring, forearm, inlays, into handle wood then a linen wrap, then into your hand.

wood pin cue, viberations travel through tip, pad, shaft, joint ring wood pin, joint ring, wood handle into your hand.

if both cues were constructed same materials with the same quality worksmanship, which do YOU think would give you the best feel?

Muttonchops

Banned

Iv'e been looking at Eddie Farris cues on the internet, it looks like he makes wood joints? I haven't been able to find a way to contact him? He looks like he's not a puppy mill cue maker?

They hit like a one-piece

That is my impression as well. I have one of Mr. Starkey's (desi above) titlist conversions with a wood pin. I really like it.

Muttonchops

Banned

DURABILITY i build wood pin cues and carry an extra pin in my cue case. when i am ask about durability, i just take the pin out and hand it to the person with the question, and tell him to go ahead and snap it in half. no one has ever broken one.

drop a metal pin cue and let the pin hit first and you might bend the pin, with wood it gives a bit then flexes back.

i have sold hundreds of cues and never had one returned with a broken pin.

HIT is a figment of YOUR imagination, as each person's is different.

each person is different, so i will tell you my way of thinking. viberations traveling from the tip to your grip hand in a normal cue, leather tip strikes ball, viberations goes through ferrule, shaft ,joint ring, stainless joint, brass insert, steel pin, joint ring, forearm, inlays, into handle wood then a linen wrap, then into your hand.

wood pin cue, viberations travel through tip, pad, shaft, joint ring wood pin, joint ring, wood handle into your hand.

if both cues were constructed same materials with the same quality worksmanship, which do YOU think would give you the best feel?

That snapping a wood pin in half is all about physics. I would challenge any strong man to do it. Put a shaft on the cue and then leverage comes into play, it's a different story then?

Last edited:

I have never owned one. The wood Joint Pins, do they stand up well? are they very durable? what do they hit like? would you prefer them over the the brass or steel or G-10?

A wood pin is okay but you will need a longer case. And if it ever breaks off, it's easy to change the joint for someone with a lathe.

chops

having done a few experiments with breakage on the wood pin, i quite understand leverage, every time i have done a break test, the shaft fails before the joint pin. i believe that is because the shaft is only sealed, and the joint pin has been treated to make it harder. i really do not know, i just know under normal usage i have never had one fail.

having done a few experiments with breakage on the wood pin, i quite understand leverage, every time i have done a break test, the shaft fails before the joint pin. i believe that is because the shaft is only sealed, and the joint pin has been treated to make it harder. i really do not know, i just know under normal usage i have never had one fail.

I know that when Helmstetter started making his wood pin 3-C cues, it completely elevated that game. The first year the Japanese players used them in the World Championship, they finished 1 -2 and I was told that if they could have sent 5 players they would have captured the top five spots. The next years, everybody had one. I don't play very good 3-C, but I'm twice as good a player using one. I don't know if its the pin, the taper, the tip size, the shortness, the weight or a combination of them that made the cues so effective.

At the time I was told that Helmstetter had done shock wave tests and the shock from the hit traveled down the center of the cue, which was why Helmstetter choose the wooden pin. Since then I've been told that is not true and that the shock is transferred mainly on the outside surfaces, so who knows?

Tad once told me that a cue he built for me was "good as one-piece" meaning that he, as a cue builder was aspiring to make his 2 piece cue play as good as a one-piece. When you think about it, if that is the goal, maintaining as much wood as you can in the joint would seem to only make sense.

Kevin

At the time I was told that Helmstetter had done shock wave tests and the shock from the hit traveled down the center of the cue, which was why Helmstetter choose the wooden pin. Since then I've been told that is not true and that the shock is transferred mainly on the outside surfaces, so who knows?

Tad once told me that a cue he built for me was "good as one-piece" meaning that he, as a cue builder was aspiring to make his 2 piece cue play as good as a one-piece. When you think about it, if that is the goal, maintaining as much wood as you can in the joint would seem to only make sense.

Kevin

My question before and still is for wood is the wear.

I have the same question for years on the "Southwest" metal pin going into wood threads.

It seems to me that the wood threads would wear and not have a tight fit. I have had a Southwest shaft that was loose because of the shaft threads were worn.

The solutions were many and seemed to be short lived, without plugging it and then retapping it. :angry:

So maybe this wear is lessoned becasue of the threads on the pin being wood, IDK.

It just seems the old Szamboti piloted shaft makes the most sense to me, just because of the wear issue.

But it seems that the "Southwest" pin going into wood threads is probably the most popular joint....

Maybe its the engineer in me thinking too much about wear that is so minute that it really doesnt matter.

Ken

I have the same question for years on the "Southwest" metal pin going into wood threads.

It seems to me that the wood threads would wear and not have a tight fit. I have had a Southwest shaft that was loose because of the shaft threads were worn.

The solutions were many and seemed to be short lived, without plugging it and then retapping it. :angry:

So maybe this wear is lessoned becasue of the threads on the pin being wood, IDK.

It just seems the old Szamboti piloted shaft makes the most sense to me, just because of the wear issue.

But it seems that the "Southwest" pin going into wood threads is probably the most popular joint....

Maybe its the engineer in me thinking too much about wear that is so minute that it really doesnt matter.

Ken

My question before and still is for wood is the wear.

I have the same question for years on the "Southwest" metal pin going into wood threads.

It seems to me that the wood threads would wear and not have a tight fit. I have had a Southwest shaft that was loose because of the shaft threads were worn.

The solutions were many and seemed to be short lived, without plugging it and then retapping it. :angry:

So maybe this wear is lessoned becasue of the threads on the pin being wood, IDK.

It just seems the old Szamboti piloted shaft makes the most sense to me, just because of the wear issue.

But it seems that the "Southwest" pin going into wood threads is probably the most popular joint....

Maybe its the engineer in me thinking too much about wear that is so minute that it really doesnt matter.

Ken

Ken:

I can't comment on the wood pin "wear and tear over time" thing (I think I have a few questions about that, myself).

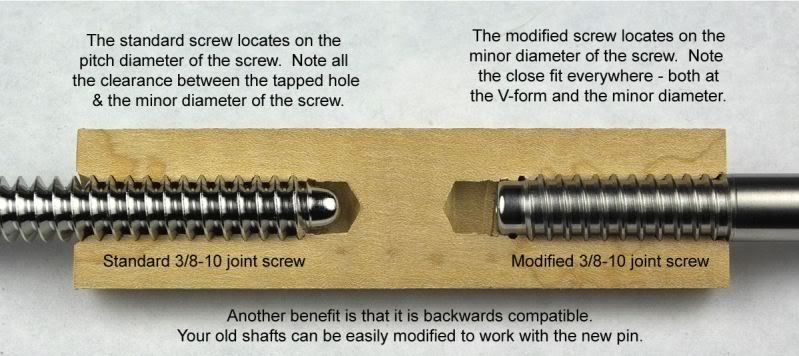

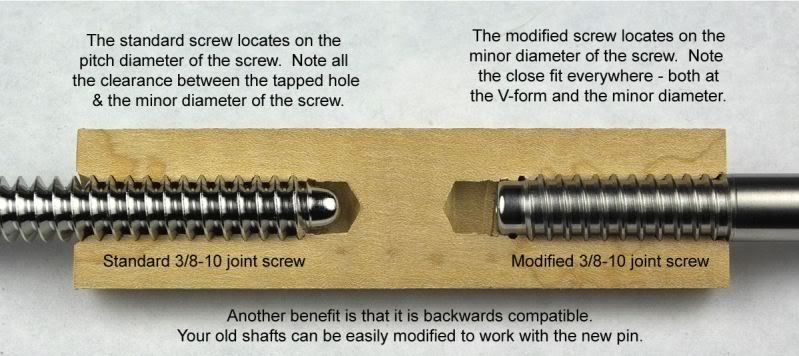

But I can comment on the same concerning metal pins. One of the issues with a "big pin" (metal) going into bare wood, is the issue of the wood threads themselves. I.e. the fact that the wood has to be cut where the threads themselves terminate into a "V" and "^" cut -- i.e. the wood terminates into points at the bottoms and tops of the threads themselves. Since we're cutting into wood "with the grain," the grain runs parallel with the direction of the threads, as they cut into the wood. Thus, the tops of wood "^" points at the top of the threads tend to break off in increasing regularity, because this is the weak spot in the design -- having the grain run parallel (horizontal) to the tops of the "^" wood points makes those points vulnerable to splitting and shearing with pressure inherent in a screw pin. That's why when you unscrew a "big pin" 3/8x10 cue, you tend to see saw dust or bits of wood come out of the shaft.

So, to address this issue with wood points breaking off the tips of the wood threads, the idea that the tops of these points would be either rounded or flattened came about. Hence the introduction of the Radial and Modified 3/8-10 pin:

Also look at this close-up image (too big, dimensions-wise, to post here as an embedded image):

http://dzcues.com/images/joints/IMG_3047a.jpg

Hope this is helpful,

-Sean

Last edited:

why would you need a longer case?

A shaft with a wood pin is 31 inches long. Lots of cases don't hold a shaft that long.

i used a helmstetter wood pin cue ( with a pool taper) for at least 10 years as a break cue. played nearly daily and the joint is as good today as when it was new.

also shot with another for as many years, and it feels very light without the steel joint's weight and follow thru was effortless. cues are a little back end heavy, which was fine with me.

could be my imagination, but i always felt like i got more english with less deflection on long shots but more deflection when cb and ob were close.

also shot with another for as many years, and it feels very light without the steel joint's weight and follow thru was effortless. cues are a little back end heavy, which was fine with me.

could be my imagination, but i always felt like i got more english with less deflection on long shots but more deflection when cb and ob were close.

A shaft with a wood pin is 31 inches long. Lots of cases don't hold a shaft that long.

Mr. Starkey's pins are on the cue butt (the one I have is).

Ken:

I can't comment on the wood pin "wear and tear over time" thing (I think I have a few questions about that, myself).

But I can comment on the same concerning metal pins. One of the issues with a "big pin" (metal) going into bare wood, is the issue of the wood threads themselves. I.e. the fact that the wood has to be cut where the threads themselves terminate into a "V" and "^" cut -- i.e. the wood terminates into points at the bottoms and tops of the threads themselves. Since we're cutting into wood "with the grain," the grain runs parallel with the direction of the threads, as they cut into the wood. Thus, the tops of wood "^" points at the top of the threads tend to break off in increasing regularity, because this is the weak spot in the design -- having the grain run parallel (horizontal) to the tops of the "^" wood points makes those points vulnerable to splitting and shearing with pressure inherent in a screw pin. That's why when you unscrew a "big pin" 3/8x10 cue, you tend to see saw dust or bits of wood come out of the shaft.

So, to address this issue with wood points breaking off the tips of the wood threads, the idea that the tops of these points would be either rounded or flattened came about. Hence the introduction of the Radial and Modified 3/8-10 pin:

Notice how much better the wood mates with the pin, where the wood itself never terminates into a "^" point at the top of the threads. Here is where the Radial (rounded wood thread tops) and Modified 3/8-10 (flattened wood thread tops) have the advantage. Wear and tear is greatly lessened, and the joint in general just "mates" better.

Also look at this close-up image (too big, dimensions-wise, to post here as an embedded image):

http://dzcues.com/images/joints/IMG_3047a.jpg

Hope this is helpful,

-Sean

Sean -

Picture helps.

Thanks.

Ken

cue length

if you have a 29 inch butt with a steel pin that is 1 1/2 inches long, that makes the total length 30 1/2 inches

now if you have a 29 inch butt with a 1 1/2 inch long wood pin, what would be the total length of this butt ?????

the cues i build have the pin in the butt, most are 57 or 58 inches long and i have never heard or seen anyone having trouble putting them in any cue case.

if you have a 29 inch butt with a steel pin that is 1 1/2 inches long, that makes the total length 30 1/2 inches

now if you have a 29 inch butt with a 1 1/2 inch long wood pin, what would be the total length of this butt ?????

the cues i build have the pin in the butt, most are 57 or 58 inches long and i have never heard or seen anyone having trouble putting them in any cue case.

if you have a 29 inch butt with a steel pin that is 1 1/2 inches long, that makes the total length 30 1/2 inches

now if you have a 29 inch butt with a 1 1/2 inch long wood pin, what would be the total length of this butt ?????

the cues i build have the pin in the butt, most are 57 or 58 inches long and i have never heard or seen anyone having trouble putting them in any cue case.

Well...I'm talking about the Kaiser and Panther break cues with the wooded pin on the shaft.:thumbup:

I don't know anything about your cues.:smile: