Guys, I need help picking a cue building lathe. I currently use 2 metalworking lathes, but I want something more portable and specialized. I only work with straight taper, but would like to try a tapering bar, so I do not have to offset the tail stock. etc. I was looking at Cuesmith Deluxe vs. Brianna. I think, value for the money, I am leaning toward Brianna. However, I am not sure I will be able to drill deeper holes (10 inches) on Brianna lathe with that small tail stock. Does anyone with any experience with these machines have any information/advice for me? Thank you in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Choosing a cuebuilding lathe.

- Thread starter BKB

- Start date

Value over money just go spend the 3k+ on the delux.....or don't listen to anyone go buy a cheaper lathe and then end up going buy the hightower anyway....

if you CAN'T spend the money to buy it then stick to tooling out your machine lathes....add an indexer/taper bars etc....

-Grey GHost-

if you CAN'T spend the money to buy it then stick to tooling out your machine lathes....add an indexer/taper bars etc....

-Grey GHost-

good advice

Very good advice!

Value over money just go spend the 3k+ on the delux.....or don't listen to anyone go buy a cheaper lathe and then end up going buy the hightower anyway....

if you CAN'T spend the money to buy it then stick to tooling out your machine lathes....add an indexer/taper bars etc....

-Grey GHost-

Very good advice!

Very good advice!

Portability takes the Engine lathes out of the picture. His only option is to choose between the few cue-specific machines offered.

Value over money just go spend the 3k+ on the delux.....or don't listen to anyone go buy a cheaper lathe and then end up going buy the hightower anyway....

if you CAN'T spend the money to buy it then stick to tooling out your machine lathes....add an indexer/taper bars etc....

-Grey GHost-

Thank you for your advice. Can you tell me specifically what I would get with Deluxe, that I will not get from another lathe?

In reality, I just need to add a rear chuck to one of the lathes to make my life much easier. That should cost around $400 (I am not making an adopter... + the cost of another chuck) Now I am forced to do a joint before tapering, which does not always work right and is very nerve wracking. Also, facing is a huge problem.

However, I want a lighter machine that I would be able to place on a bench with wheels and roll around the shop. I do not really need a taper bar, but would like to try it. It is also nice to be able to work between centers. Finally, the length of the machine is an issue, as well.

I do not want to spend $3,000, but would go $1,500 - $2,300 on a right deal.

Thank you for your input everyone.

Very good advice!

Used your spur driver. Thank you!!! It is amazing. One of these days I will post a photo of the one I build and use before I got yours. Never got the idea of the floating center, so I move the driving pins. Takes time...

I can probably provide a ready to use rear chuck and adapter for your metal lathe for $175.Thank you for your advice. Can you tell me specifically what I would get with Deluxe, that I will not get from another lathe?

In reality, I just need to add a rear chuck to one of the lathes to make my life much easier. That should cost around $400 (I am not making an adopter... + the cost of another chuck) Now I am forced to do a joint before tapering, which does not always work right and is very nerve wracking. Also, facing is a huge problem.

However, I want a lighter machine that I would be able to place on a bench with wheels and roll around the shop. I do not really need a taper bar, but would like to try it. It is also nice to be able to work between centers. Finally, the length of the machine is an issue, as well.

I do not want to spend $3,000, but would go $1,500 - $2,300 on a right deal.

Thank you for your input everyone.

If you want full blown cue building capability in your smaller lathe then your budget will most likely only allow you to go after a used lathe. But if you want to deck one of your large lathes out for tapering then you can go less expensively with an assembly lathe. Since portability is a desire I would suggest a lighter assembly lathe instead of a full blown Deluxe. Add taper bars to one of your metal lathes and dedicate it to tapering and you will have a really nice shop set up.

I have a hightower Deluxe and it will do anything and everything you need to build cues, save inlays. The taper bars that come with it are great, do yourself a favor and spend the money on the deluxe !

You could do worse, but not better for the money. Just my opinion

You could do worse, but not better for the money. Just my opinion

I do not really need a taper bar, but would like to try it.

If you think you don't need a taper bar, then you haven't used a taper bar. Correctly set-up I find it an indispensable accessory. Certainly there are other ways to acheive the same results. But my advise is to save yourself time and aggravation by adding a nice taper bar attachment.

Smiles,

Alan

I can probably provide a ready to use rear chuck and adapter for your metal lathe for $175.

If you want full blown cue building capability in your smaller lathe then your budget will most likely only allow you to go after a used lathe. But if you want to deck one of your large lathes out for tapering then you can go less expensively with an assembly lathe. Since portability is a desire I would suggest a lighter assembly lathe instead of a full blown Deluxe. Add taper bars to one of your metal lathes and dedicate it to tapering and you will have a really nice shop set up.

Thank you for your reply! $175 is a great price. I may take you up on your kind offer, if I do not find a specialized lathe that would make me happy in terms of size/quality/price. I have no problem with tapering, because I only use a straight taper (i build cues for Russian pyramid only, or, rather, try to build cues as a hobby...) Thus, I get where I want to be simply by offsetting the tail stock. A taper bar would only add convenience of not having to reset my tail stock when I need to drill. Unless I am missing something due to no experience with taper bar...

I just want a complete cue building lathe, that is easy to move. I moved my shop ones, and it cost $3,500. I am not doing that again.

If you have enough length between centers on your lathe, simply chuck up a boring head with a live center in your tail stock. Then offset the boring head to get your taper, and leave the tail stock dead center.

This is what I do now (I used to kick the tail stock back like you do now) and this is SO much easier. It is also repeatable, and you could have several tapers pre-set on several boring head arrangements for under 2 grand...

Might be a thought...

See here:

This is what I do now (I used to kick the tail stock back like you do now) and this is SO much easier. It is also repeatable, and you could have several tapers pre-set on several boring head arrangements for under 2 grand...

Might be a thought...

See here:

Attachments

If you have enough length between centers on your lathe, simply chuck up a boring head with a live center in your tail stock. Then offset the boring head to get your taper, and leave the tail stock dead center.

This is what I do now (I used to kick the tail stock back like you do now) and this is SO much easier. It is also repeatable, and you could have several tapers pre-set on several boring head arrangements for under 2 grand...

Might be a thought...

See here:

This is a great idea, but I do not have enough distance.

I agree with the others, a deluxe is the way to go. I bought mine used for $1800 and it was the best amount I've spent so far. I know your pain, I used an Atlas for years before having the money to get my deluxe. Used a staedy rest with a bearing to do the facing and joint work, BIG P.I.A. If you wait and watch there are always one or two up for sale on here every couple weeks it seems. You may find a great deal that fits your budget.

They are pretty lightweight considering the length and such, so moving it isn't too bad with 2 people.

I recommend talking to Chris directly to get info about the lathes, he may even be able to setup a 'custom' setup for you.

Good luck,

Dave

They are pretty lightweight considering the length and such, so moving it isn't too bad with 2 people.

I recommend talking to Chris directly to get info about the lathes, he may even be able to setup a 'custom' setup for you.

Good luck,

Dave

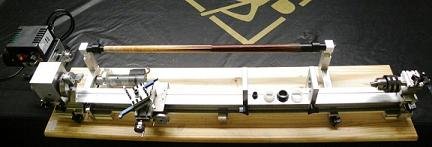

Auto feed copier taper bar combo Cue Building Lathe

TO BUY THE LATHE WITH EVERYTHING $2600 WITH FREE SHIPPING.( INCLUDES ROUTER AND BRACKET)

Auto feed has built in speed control and is its reversible too, you will be able to set up the stop ( off/Rev) switch anywhere along the 44" travel.

How this kit works:

The kit comes with 3 dove tail pieces predrilled to replace the 3 board mounted bracket to u-channel, once you replace those brackets with the dove tail pieces, then you can just slide the bed over the dovetail coupler blocks ( already mounted to board) Clamp down the blocks to hold the bed down.

Now you got dovetail on the top and bottom, the bottom dovetail is also used to reposition the copier ( short or long pieces).

The copier has 2 true self centering heads, below that, you will see a slot, that is where the regular taper bar( similar to hightowers ) will mount. So, if you want to make your own taper you still can, and if you just want to copy a certain taper, you can too.

I also added the indexer now which threads on instead of the rear chuck. The indexer is also a pulley for optional rear belt drive. The same motor can be re-mounted 180deg off its horizontal axis for rear belt drive, which is standard for my 1/3HP motor and my portable toolbox lathe.

Starting September 1, all my Cue Lathe line up will have a 1.4" Bore headstock standard, with the best prices and best quality around.

P.S. The router bracket comes with both horizontal for turning down wood and vertical for making point. You can call Bassel Elshaar for more info. @

248-884-4469

TO BUY THE LATHE WITH EVERYTHING $2600 WITH FREE SHIPPING.( INCLUDES ROUTER AND BRACKET)

Auto feed has built in speed control and is its reversible too, you will be able to set up the stop ( off/Rev) switch anywhere along the 44" travel.

How this kit works:

The kit comes with 3 dove tail pieces predrilled to replace the 3 board mounted bracket to u-channel, once you replace those brackets with the dove tail pieces, then you can just slide the bed over the dovetail coupler blocks ( already mounted to board) Clamp down the blocks to hold the bed down.

Now you got dovetail on the top and bottom, the bottom dovetail is also used to reposition the copier ( short or long pieces).

The copier has 2 true self centering heads, below that, you will see a slot, that is where the regular taper bar( similar to hightowers ) will mount. So, if you want to make your own taper you still can, and if you just want to copy a certain taper, you can too.

I also added the indexer now which threads on instead of the rear chuck. The indexer is also a pulley for optional rear belt drive. The same motor can be re-mounted 180deg off its horizontal axis for rear belt drive, which is standard for my 1/3HP motor and my portable toolbox lathe.

Starting September 1, all my Cue Lathe line up will have a 1.4" Bore headstock standard, with the best prices and best quality around.

P.S. The router bracket comes with both horizontal for turning down wood and vertical for making point. You can call Bassel Elshaar for more info. @

248-884-4469

Attachments

Last edited:

For the money I just picked up 2 cue building lathe machines from Bassel "customcuelathe".

Send him a pm and talk to him. He can build you something on your budget. I do feel that a Deluxe Hightower and a CCL are the best in my opinion. Is just a matter of price point. I have both doing different things. Bassel should chime in here very soon.

Send him a pm and talk to him. He can build you something on your budget. I do feel that a Deluxe Hightower and a CCL are the best in my opinion. Is just a matter of price point. I have both doing different things. Bassel should chime in here very soon.

Choosing a cue building lathe is tough, if your only options are hightower and Brianna. I know Hightower's deluxe lathe is a great cue building lathe, but a bit pricey.

At custom cue lathes we build a lathe exactly the way you want it, if you need a custom made tail stock no problem. All my headstocks are garenteed to have better than 0.0025" runout, give me a call @248-884-4469 or email to customcuelathes@yahoo.com or just drop me a PM

My cue building lathes starts at $1399 and go up to $2599 with every option and all the tooling.

I offer the best autofeed set up available ( lead screw set up with independent gear motor with speed control)

the best part of all this is my new custom U-channel, I will be posting my new cue building lathe pics on Monday, more videos comming soon to. Looking forward to hear back from

You

Best Regards

Bassel

At custom cue lathes we build a lathe exactly the way you want it, if you need a custom made tail stock no problem. All my headstocks are garenteed to have better than 0.0025" runout, give me a call @248-884-4469 or email to customcuelathes@yahoo.com or just drop me a PM

My cue building lathes starts at $1399 and go up to $2599 with every option and all the tooling.

I offer the best autofeed set up available ( lead screw set up with independent gear motor with speed control)

the best part of all this is my new custom U-channel, I will be posting my new cue building lathe pics on Monday, more videos comming soon to. Looking forward to hear back from

You

Best Regards

Bassel

I would appreciate it and kindly ask that you quit using my name in your advertisements and posts.Choosing a cue building lathe is tough, if your only options are hightower and Brianna. I know Hightower's deluxe lathe is a great cue building lathe, but a bit pricey.

At custom cue lathes we build a lathe exactly the way you want it, if you need a custom made tail stock no problem. All my headstocks are garenteed to have better than 0.0025" runout, give me a call @248-884-4469 or email to customcuelathes@yahoo.com or just drop me a PM

My cue building lathes starts at $1399 and go up to $2599 with every option and all the tooling.

I offer the best autofeed set up available ( lead screw set up with independent gear motor with speed control)

the best part of all this is my new custom U-channel, I will be posting my new cue building lathe pics on Monday, more videos comming soon to. Looking forward to hear back from

You

Best Regards

Bassel

Thank you for your consideration in this matter.

Auto feed copier taper bar combo Cue Building Lathe

TO BUY THE LATHE WITH EVERYTHING $2600 WITH FREE SHIPPING.( INCLUDES ROUTER AND BRACKET)

Auto feed has built in speed control and is its reversible too, you will be able to set up the stop ( off/Rev) switch anywhere along the 44" travel.

How this kit works:

The kit comes with 3 dove tail pieces predrilled to replace the 3 board mounted bracket to u-channel, once you replace those brackets with the dove tail pieces, then you can just slide the bed over the dovetail coupler blocks ( already mounted to board) Clamp down the blocks to hold the bed down.

Now you got dovetail on the top and bottom, the bottom dovetail is also used to reposition the copier ( short or long pieces).

The copier has 2 true self centering heads, below that, you will see a slot, that is where the regular taper bar( similar to hightowers ) will mount. So, if you want to make your own taper you still can, and if you just want to copy a certain taper, you can too.

I also added the indexer now which threads on instead of the rear chuck. The indexer is also a pulley for optional rear belt drive. The same motor can be re-mounted 180deg off its horizontal axis for rear belt drive, which is standard for my 1/3HP motor and my portable toolbox lathe.

Starting September 1, all my Cue Lathe line up will have a 1.4" Bore headstock standard, with the best prices and best quality around.

P.S. The router bracket comes with both horizontal for turning down wood and vertical for making point. You can call Bassel Elshaar for more info. @

248-884-4469

how much is Bassel paying? I got a handful of cues that will be done in a month or so that I'm going to have to sell.....I could be your pimp too

I guess you gotta ask yourself.... "Are two pimps really better than one?"

pimpin' since pimpin'

-Grey Ghost-

Oh and one more thing lets not BS anyone.....THE HIGHTOWER IS NOT PRICEY....ITS A DAM STEAL FOR THE QUALITY & CAPABILITIES!!! Its the szamboti of cue making specific, built to order turning machines. Its not my opinion, its basically the vast majority of cuemakers opinions when speaking of non-engine style lathes. He's been around since b/f there was any such thing as a cue making lathe that you could just pay for.....you had to build them from nothing yourself....now you have engine lathes that you still have to tool out, you have the unique products cue making lathe, you have chris hightowers signature deluxe model and then you have a few hightower design knockoffs and that even goes for some accessories too....and thats the bare bones facts, its not mean or nice, just the plain truth....if the hightower was not the shizz nit as per form/function then you would not see the knock offs....

Last edited:

Thank you for all responses. I had no idea there were so many more choices in this price range. I guess, I should not have asked for a comparison, for it incites a riot around these parts. And, for this I apologize. I guess I am going to have to compare the specs and see what I can get inside my budget. Maybe I should start by adding a rear chuck to my headstock(which will give me more time pick the right one), because doing joints without it kills me and drives me to buy a cue lathe ASAP. Thank you all again, and please do not fight because of my silly question wording.