Joe

You have some ego, I must say, for some one who didn't know the first thing about how to drill a straight hole, you would be the last person on earth I want learn from. Besides I think you are full of it.

First of all I sat back and let you take shot after shot at me without saying anything, but now I will.

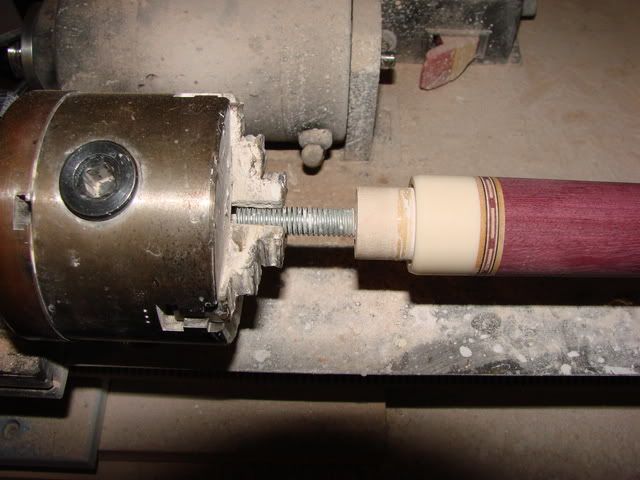

Second your mandrels look like harden steel ground on a lathe with a belt sander. It was you who posted last week if anyone is interested in harden steel mandrels.

assuming that everything you said is true, that you ground them between centers and the brass inserts don't go all the way, I am sure everyone would like to know how you center drilled the carbide prior to the grinding process.

Just to clear one more thing, people who were unhappy with my carbide mandrels got their money back. Everyone here is always interested in making money, for me I am in it this business for the passion and to make a little extra money.

Don't take this as an attack or stirring the pot, like you say.

If you think you can make better mandrels than me or the other guys that make them, good luck to you, it's always good to have a healthy competition, that will benefits everyone else and yields fair prices to everyone wanting them, and it will push everyone to make a better product.

I just hope you would act a bit more mature about this whole thing.

Good luck to you with the mandrels, and may the best mandrels win.

Regards