Still waiting on anyone else to chime in.......

BTW - Jive and Smokey probably use/used more real leather than all the case makers combined have in a lifetime.

Leather is not charged the same for all thicknesses. If a supplier is charging the same then they are over charging for the thin.

Tooling leather is tanned with chemicals derived from plant sources, often oak trees. Nappa leather is tanned using chromium which speeds up the process and results in a very supple leather. There are other ways to tan leather including using animal brains. It's worth a trip around the internet to read about the various ways leather is tanned and it's history.

Leather itself is graded on appearance as to quality for top grains. Top grains are leathers where the surface has not been altered and all the marks from the animal's life have been left alone. So when the tanning process is done the leather retains all the bite marks, scratches, scars and so on. This is preferred by some as it's the epitome of "leather" much the same as some cue buyers prize highly figured wood.

Corrected grain is when the surface has been sanded to make the surface smoother. This allows the leather to be embossed with any type of texture and is the basis for all the "prints".

There are two types of embossing, a direct print on the leather much the same as a single leather worker would make a stamp impression and a painting/bonding method where the leather is bonded to a synthetic surface and the texture is then imprinted on that. From a quality standpoint the first type of embossing is preferred because the texture is a permanent part of the leather. With the second type the texture can be removed with vigorous scratching. However the durability of the embossed layer on the second type varies by manufacturer and it can be extremely durable or very weak. The only way to find out is to test it as from appearance it's the same.

A cow skin is about an inch thick. So the skin is split into layers and the top layer, the one where the hair comes out is the top grain layer. All other layers are called splits and they are less expensive. From a durability standpoint they are the same as the top layer but they MUST be treated on the surface to achieve a suitable appearance.

From a consumer standpoint the quality of the leather has to do with appearance and durability. How long will it look good, what do I have to do to keep it looking good, and how strong is it?

The thing is that "leather" encompasses many different types and tannages and treatments. So it's nearly impossible for anyone to say that they use the best leather because no one agrees as to whats best.

Rusty says the best tooling leather comes from Herman Oak or Wicket and Craig. But then I get tooling leather that's imported from Brazil that is great as well. There are tanneries all over the world who all produce leather in about the same manner. In my experience it's best to search for leather in person and feel the material and test it before buying it. Then you hope to find a good supplier who can provide consistent material. This is where the value of a Herman Oak comes in because they have been consistent in what they supply.

From a consumer standpoint there is ZERO way to tell whether a piece of tooled leather came from any particular supplier. None. When leather is tooled the result depends on the way the leather was worked more than the starting material. I can guarantee you that any good leather worker can make beautiful pieces out of tooling leather from any source. One brand might be easier to work with but that doesn't mean that it's better in quality than any other brand when looking at the finished piece.

Getting into whose leather is "better" is a quagmire. It's akin to cue makers claiming that their wood is better than the wood of other cue makers. There are simply too many varieties to make that call. If one guy says that he only uses leather from a particular brand because it's the "best" I can provide quotes from other leather workers who claim that a competing brand is better.

We use all types of leather in our cases. For each type we have different techniques to work it so that the resulting cue case is as strong and durable as we want it to be. This includes hand-sanding the edges so that they fold properly, bonding the leather to other materials to increase stiffness, working it with oil or other methods to make it softer, molding it over wood molds with water and many many many more techniques that are invisible to the consumer. All of this encompasses the craft of leather working. The more varieties of leather you use the more you need to know and do to create great finished products. I feel pretty good about our ability to turn out cases using any type of leather.

This is an example of a case using nappa leather, eel print, and veg tan tooling leather.

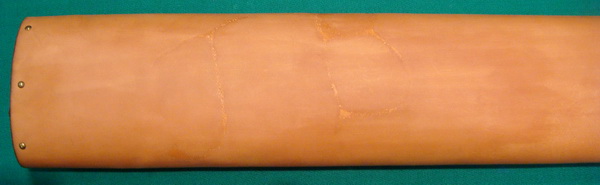

This is oil tan with veg tan:

Nappa with croc print:

This one is thinner tooling leather which we dyed to the customer's color preference. Also we use goat skin for the piping (the line that goes around the edges) and dye it to match the rest of the case:

Croc print with tooling leather:

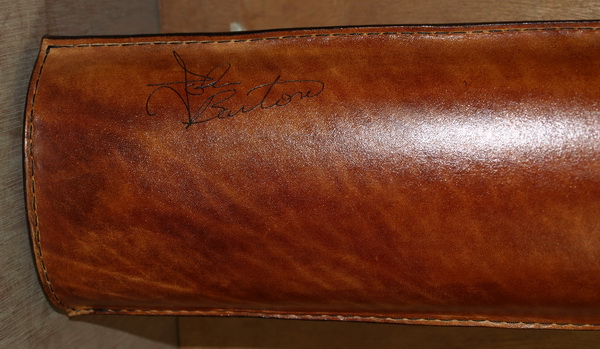

Full Veg Tan Tooling leather:

As a consumer you can only study the available information and go to leather goods stores to familiarize yourself with the different types and how they feel.

For me personally it's the fit and finish that is more important than the type of leather used. Any material can be worked into a good product. I make a case out of vinyl that is indistinguishable from leather. Anyone touching and feeling it thinks it's great leather.

You can take a piece of cowhide with blotches and defects and make it into a great case with proper leather working techniques. And often these make the most interesting cases. In contrast you can start with the most expensive and clean piece of Herman Oak saddle leather and make a crappy product.