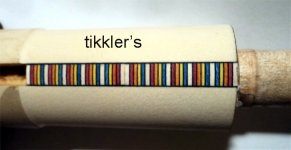

I would like to make some new ring billets with a veneer. Kind of old school type rings, similar to this scruggs. I havent worked with veneers yet, so I am wondering about pressing a black, blue, black veneer and how much extra room to allow for glue and such when I do this. I can buy the veneers in .030 or .035 or .040 ... I would like to buy the .040, but I am wondering if anyone that has experience with this can chime in and maybe save me time and mistakes.

I am thinking I will try to fit a 3 veneer stack into a .125 slot, so .040 (.120)makes it really tight or .035 (.105) seems like it has a litte extra room, but I'm just not sure how much glue they absorb and such when you stack veneers.

Thanks,

dakota

Thanks,

dakota

I am thinking I will try to fit a 3 veneer stack into a .125 slot, so .040 (.120)makes it really tight or .035 (.105) seems like it has a litte extra room, but I'm just not sure how much glue they absorb and such when you stack veneers.

Thanks,

dakota

Thanks,

dakota