You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My house cues are in timeout!

- Thread starter johnnyjumpjump

- Start date

Steam has been used to move wood for years. You can turn it into spaghetti if you want too. Interesting to see if your experiment works long term or not. That will be the big challenge. But I like the idea!

Maybe they could use a sauna treatment if this fails!

Maybe they could use a sauna treatment if this fails!

I mean, you have 75+ year old cues hanging to straighten. They've been bent for 60 years. You're going to need a little more oomph than gravity

johnnyjumpjump

New member

You should be ok as long as you dry your shaft and butt after the shower.

I usually dry both a lot after a shower - oh, you mean the cues!

I usually dry both a lot after a shower - oh, you mean the cues!

johnnyjumpjump

New member

You're going to need a little more oomph than gravity

Well, I plan to combine gavity with time. I will test after one month (maybe it will take years).

Well, I plan to combine gavity with time. I will test after one month (maybe it will take years).

I always do that after I shower.You should be ok as long as you dry your shaft and butt after the shower.

middleofnowhere

Registered

Have you done the research and understand why wood warps?Hope they learn their lesson!

Yep, I make canes, walking sticks, and staffs. I have used this method to straighten an otherwise perfect piece of wood...although I don't worry about getting them arrow straight such as a pool cue.Steam has been used to move wood for years. You can turn it into spaghetti if you want too. Interesting to see if your experiment works long term or not. That will be the big challenge. But I like the idea!

Maybe they could use a sauna treatment if this fails!

I usually hang a 5 or 10 pound weight off of the bottom to provide a little extra oomph...I mean, you have 75+ year old cues hanging to straighten. They've been bent for 60 years. You're going to need a little more oomph than gravity

middleofnowhere

Registered

Usually use steam to bend wood.Yep, I make canes, walking sticks, and staffs. I have used this method to straighten an otherwise perfect piece of wood...although I don't worry about getting them arrow straight such as a pool cue.

I usually hang a 5 or 10 pound weight off of the bottom to provide a little extra oomph...

Last edited:

Of course, and if you are straightening wood that is already bent, you are simply bending it in the opposite direction.Usually use steam is used to bend wood.

middleofnowhere

Registered

It won't stay straight. It'll repeat what it did before as it dries out based on how the grain of the wood runs. The wood bent for a reason in the first place.Of course, and if you are straightening wood that is already bent, you are simply bending it in the opposite direction.

There's a difference between bending wood to make the ribs of a canoe and trying to end up with a piece of wood straight within thousands of an inch for a pool cue shaft.

johnnyjumpjump

New member

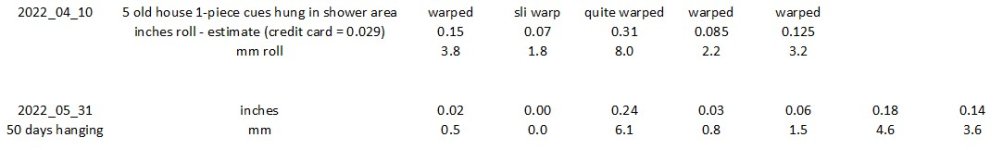

I gauged the condition of the cues (4 1950’s vintage Brunswick Tru Balance cues and 1 1960’s Dufferin Red Leaf) after 50 days in timeout.

All 5 cues had improved. The straightest Tru Balance cue improved from 1.8mm of roll to perfectly straight and was returned to the wall rack. 3 cues that started with 2.2-3.8mm of roll improved to 0.5-1.5mm of roll and were returned to timeout. The quite crooked Tru Balance cue at 8mm of roll (about 10 credit cards) improved to about 6mm of roll (about 8 credit cards) and was immediately sent back to timeout.

2 additional cues were added to the shower hanging group. For details see the accompanying spreadsheet screenshot.

I will be monitoring the condition of the straight cue returned to the wall rack.

BTW, I hang my playing cues and my better production and custom cues by the distal parts of their shafts, which I am convinced helps to maintain their straight condition.

All 5 cues had improved. The straightest Tru Balance cue improved from 1.8mm of roll to perfectly straight and was returned to the wall rack. 3 cues that started with 2.2-3.8mm of roll improved to 0.5-1.5mm of roll and were returned to timeout. The quite crooked Tru Balance cue at 8mm of roll (about 10 credit cards) improved to about 6mm of roll (about 8 credit cards) and was immediately sent back to timeout.

2 additional cues were added to the shower hanging group. For details see the accompanying spreadsheet screenshot.

I will be monitoring the condition of the straight cue returned to the wall rack.

BTW, I hang my playing cues and my better production and custom cues by the distal parts of their shafts, which I am convinced helps to maintain their straight condition.

Attachments

I gauged the condition of the cues (4 1950’s vintage Brunswick Tru Balance cues and 1 1960’s Dufferin Red Leaf) after 50 days in timeout.

All 5 cues had improved. The straightest Tru Balance cue improved from 1.8mm of roll to perfectly straight and was returned to the wall rack. 3 cues that started with 2.2-3.8mm of roll improved to 0.5-1.5mm of roll and were returned to timeout. The quite crooked Tru Balance cue at 8mm of roll (about 10 credit cards) improved to about 6mm of roll (about 8 credit cards) and was immediately sent back to timeout.

2 additional cues were added to the shower hanging group. For details see the accompanying spreadsheet screenshot.

I will be monitoring the condition of the straight cue returned to the wall rack.

BTW, I hang my playing cues and my better production and custom cues by the distal parts of their shafts, which I am convinced helps to maintain their straight condition.

If you have a measurable improvement, then we'll done to you man

Two things warp cues, stress and stress relief. If stress warped the wood, it has been leaning against a wall at too much of an angle for example, it can be straightened successfully and will stay straight. If it warped because of stress relief, there was a side load on this wood when it was part of the tree, then the warp will tend to return.

When turning wood for other purposes it is tempting to make use of huge limbs. It can be done if warping will add to an ornamental piece. If warping is unacceptable, this wood that has been under heavy load is almost impossible to work with. Does make some wild looking pieces sometimes if turned green and allowed to warp naturally afterwards.

Turning green wood is fun and almost dust free. Watching wood stream off in ten or fifteen feet long curls is far more fun than making cues. Katrina got my cue shop, Ida ended my ornamental turning. "Stuff" happens! I was at 250' elevation and felt safe until Ida dropped three large oaks on the house I was living in and destroyed my shop.

Hu

When turning wood for other purposes it is tempting to make use of huge limbs. It can be done if warping will add to an ornamental piece. If warping is unacceptable, this wood that has been under heavy load is almost impossible to work with. Does make some wild looking pieces sometimes if turned green and allowed to warp naturally afterwards.

Turning green wood is fun and almost dust free. Watching wood stream off in ten or fifteen feet long curls is far more fun than making cues. Katrina got my cue shop, Ida ended my ornamental turning. "Stuff" happens! I was at 250' elevation and felt safe until Ida dropped three large oaks on the house I was living in and destroyed my shop.

Hu