I purchased my Deluxe Cue Smith lathe a couple of years ago but due to life getting in the way I have just recently started learning how this all works. Having spent time designing and building UL listed control panels and also being a fan of minimal movements for tasks (not special, just cheap and lazy  ) I quickly learned I didn't like the electrical setup of the lathe in stock form. This not a dig on Chris Hightower, he builds a great product that is well respected, by me included, and I also know the motor(s) are purchased and installed as is. With that, I have made some modifications I thought I would share.

) I quickly learned I didn't like the electrical setup of the lathe in stock form. This not a dig on Chris Hightower, he builds a great product that is well respected, by me included, and I also know the motor(s) are purchased and installed as is. With that, I have made some modifications I thought I would share.

1) Indexing mod

When I first got the machine and inspected it before using it I thought there was too much play in the indexing function so I modified that shortly after getting it set up.

Here's a link to that mod:

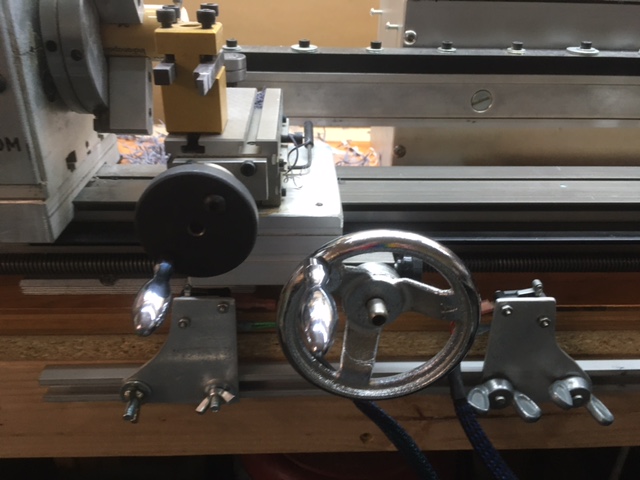

2) Power feed motor wiring and switch location

In the grand scheme of things the original setup was efficient for building the product based on the fact these products are sourced in the aftermarket but, having the speed control on the opposite end as the chuck and having to unplug the connector to change directions isn't that efficient. I modded this by removing the speed dial and installing the box on the bench face for ease of access. I then added a forward/reverse switch inline with the wiring, keeping the original connector for a future removal of the motor, if needed.

The switch on the left is a double position double throw (on/off/on) switch for forward/reverse. The speed control is mounted to the right. The on/off/on switch allows me to turn off the power feed without affecting anything else.

I will point out these are mounted on the right but the other mods on are the let. I modded this before touching the main motor and I utilized whatever length of wire was available from the factory, I will be moving/modifying the speed control wire next to the main motor mods in the future.

EDIT: The eye bolt is for an air compressor blow gun, I have a few of them around the garage.

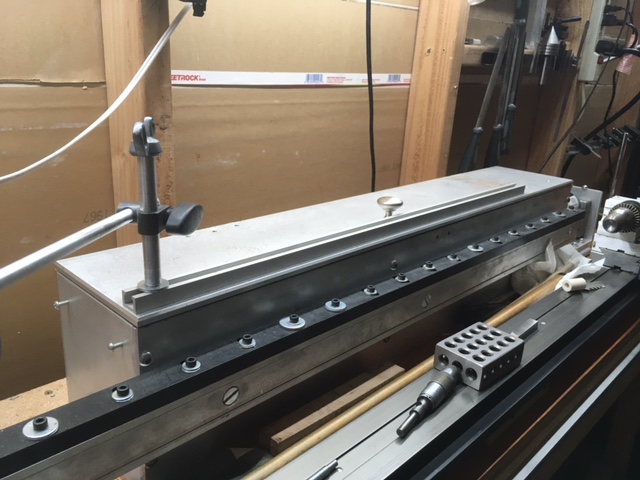

3) Adding a quick adjustment dial indicator

I learned years ago the benefit of having an easily accessible dial indicator on a lathe. I also own a Sieg C3 lathe and it has metal components close enough to use a magnetic based dial indicator but, this lathe is built out of aluminum so it's a bit harder to add a dial indicator. There are quite a few threads here about adding a dial indicator but here's my addition.

I used a regular t-track rail and built my own post and holding arm (C3 for the win). I designed the length of the t-track and holding arm to reach every point along the length of the bed of the lathe by simply loosening 1 or 2 wing nuts. I still need/want to add an adjuster in the middle of the holding arm (need to modify the original to fit) but it works for now. I can use either the vertical or horizontal wing nuts to clear the head stock. In my setup the the vertical post hits the wall before the lid so I need to align the holding post correctly when loosened so if I need to open the lid it doesn't get in the way. This is the only negative I have found far but it's easily addressed.

And for the keen viewer, yes, the indicator is bent, when building this I dropped it . But that just gives me a reason to buy a better dial indicator

. But that just gives me a reason to buy a better dial indicator

4) Sand paper storage

I have stored sand paper in a milk crate file holder for years. When I started using the lathe and needed sand paper I got tired of looking around for the piece I just used so I found a quick and simple way of mounting the crate to the bench by using some #1 Phillips wood screws spaced apart so I could hang/remove the file holder quickly. Since I installed this I have moved the switches so I need to adjust the screw location to match. I like the file holders because you can store different grits in order so they are easily accessible. I used to store all of my sand paper this way but found when switching between multiple grits so frequently it's easier to store small quantities for ease of access and I store the bulk supply elsewhere.

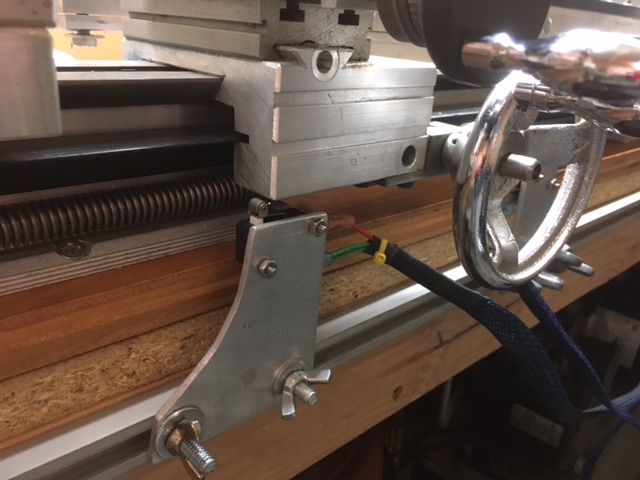

5) Reed/limiting switches

Being lazy I wanted to be able to set it and forget it, based on this I wanted to add some limiting switches. Once again I utilized a traditional t-track and made my own brackets to attach some reed switches. Sidebar - those switches came from a (broken) commercial coffee or ice maker I acquired in the late 90's. These are simple on/off reed switches with the ability to be wired normally open (NO) or normally closed (NC).

The t-track is long enough to adjust the limiting switches the entire length of the lathe bed. I wired these normally open into the main switch so when activated they cut power to the motor, and in return cuts power to the switched outlet which you use a small power strip to plug in the power feed motor, a router (think cutting points), and a dust collection system.

You will have to confirm your amp requirements of the switched outlet versus the equipment being used but I haven't got that far yet, I only have the power feed connected at this point. Sidebar: the keen viewer will notice the far left screw attaching the t-track is slightly lower than the others. This happened because I didn't pre-drill and the screw followed the least restrictive path and went between the tree rings and dropped about 1/8th inch. The consequence is the t-track dropped so I had to drill the holes oversize which means there is enough play in the brackets they move vertically so I can't simply just slide the brackets at will, I need to adjust them vertically also. Not a big enough issue to fix everything but the lesson learned - pre-drill!

EDIT: The wiring isn't 100% complete, I have some ideas for dust collection that will affect it so I left it as is for now.

6) E-stop switch/button

I wanted an easily accessible emergency on/off switch so I wired it in and used what I had. I ended up using a typical on/off toggle switch but added a switch extender (a trucker thing) and installed it near the area I would be when the lathe is on auto-mode. Eventually, I will add a traditional e-stop push button switch but it works as is.

E-stop switch

7) Main motor mods

I will preface this by, again, stating the motor is acquired and installed as is.

Once I started using the lathe I realized that having the switched outlet on the front of the motor, having the speed control on the back of the motor, and having the factory forward/reverse switch in a micro switch format wasn't conducive to actual use. Initially I thought by simply rotating the main box it would fix my problems so that was the first change. However, after doing that I quickly learned the speed adjusting/emergency stop lever was not just mechanical (by applying resistance to the motor) it was also electrical via a magnetic switch internally mounted. After figuring that out I relocated the magnetic switch to the the correct side and all was well. Sidebar: If you move the circuit board (mirrored image/dimensions) to the other side the magnet is no longer in the correct position and the lathe won't work - ask me how I know .

.

After that was sorted out, I removed the forward/reverse switch (which required a small screwdriver to easily switch) and replaced it with am ON/ON toggle switch. The thought process for that was in an emergency I didn't want to have to deal with finding the middle position of a switch as it would take too long, I added a main, easily accessed, ON/OFF switch emergency switch. For general use, I mounted the original ON/OFF switch box (fuse included) to the front of the bench as it's easily accessed and easy to switch via my thumb. I also rarely change forward/reverse so that access was not required but needed.

Then I removed the speed control dial and added some wire so I could mount it on the front of the bench for ease of access. Factory dial, simply added wire. I then built a bracket to hold the speed control and forward/reverse switches.

Reversed box and empty speed switch hole:

Back of box showing new wiring and switched outlet:

Relocated power box and bracket for speed control and forward/reverse switches:

What would I do differently?

1) Move the power feed switch/control to the left with the other on/off switches for ease of access.

2) I never would've rotating the box. Considering the time I spent compared to the fact I removed the forward/reverse and speed control switches I could've easily purchased a power cord with a flush mount connector which wouldn't have been in the way and it will never be touched.

What kind of mods have you done? I'm specifically interested in dust collection for this lathe.

1) Indexing mod

When I first got the machine and inspected it before using it I thought there was too much play in the indexing function so I modified that shortly after getting it set up.

Here's a link to that mod:

Deluxe Cue Smith indexing ring improvement - DIY

I'm going to preface this by saying I did NOT call Chris Hightower about this because I felt the lathe was not broken and once I saw it I realized how easy of a fix it was so I didn't bother Chris with the issue. I'm not sure about others but my indexing ring on my Deluxe Cue Smith had a bit of...

forums.azbilliards.com

2) Power feed motor wiring and switch location

In the grand scheme of things the original setup was efficient for building the product based on the fact these products are sourced in the aftermarket but, having the speed control on the opposite end as the chuck and having to unplug the connector to change directions isn't that efficient. I modded this by removing the speed dial and installing the box on the bench face for ease of access. I then added a forward/reverse switch inline with the wiring, keeping the original connector for a future removal of the motor, if needed.

The switch on the left is a double position double throw (on/off/on) switch for forward/reverse. The speed control is mounted to the right. The on/off/on switch allows me to turn off the power feed without affecting anything else.

I will point out these are mounted on the right but the other mods on are the let. I modded this before touching the main motor and I utilized whatever length of wire was available from the factory, I will be moving/modifying the speed control wire next to the main motor mods in the future.

EDIT: The eye bolt is for an air compressor blow gun, I have a few of them around the garage.

3) Adding a quick adjustment dial indicator

I learned years ago the benefit of having an easily accessible dial indicator on a lathe. I also own a Sieg C3 lathe and it has metal components close enough to use a magnetic based dial indicator but, this lathe is built out of aluminum so it's a bit harder to add a dial indicator. There are quite a few threads here about adding a dial indicator but here's my addition.

I used a regular t-track rail and built my own post and holding arm (C3 for the win). I designed the length of the t-track and holding arm to reach every point along the length of the bed of the lathe by simply loosening 1 or 2 wing nuts. I still need/want to add an adjuster in the middle of the holding arm (need to modify the original to fit) but it works for now. I can use either the vertical or horizontal wing nuts to clear the head stock. In my setup the the vertical post hits the wall before the lid so I need to align the holding post correctly when loosened so if I need to open the lid it doesn't get in the way. This is the only negative I have found far but it's easily addressed.

And for the keen viewer, yes, the indicator is bent, when building this I dropped it

4) Sand paper storage

I have stored sand paper in a milk crate file holder for years. When I started using the lathe and needed sand paper I got tired of looking around for the piece I just used so I found a quick and simple way of mounting the crate to the bench by using some #1 Phillips wood screws spaced apart so I could hang/remove the file holder quickly. Since I installed this I have moved the switches so I need to adjust the screw location to match. I like the file holders because you can store different grits in order so they are easily accessible. I used to store all of my sand paper this way but found when switching between multiple grits so frequently it's easier to store small quantities for ease of access and I store the bulk supply elsewhere.

5) Reed/limiting switches

Being lazy I wanted to be able to set it and forget it, based on this I wanted to add some limiting switches. Once again I utilized a traditional t-track and made my own brackets to attach some reed switches. Sidebar - those switches came from a (broken) commercial coffee or ice maker I acquired in the late 90's. These are simple on/off reed switches with the ability to be wired normally open (NO) or normally closed (NC).

The t-track is long enough to adjust the limiting switches the entire length of the lathe bed. I wired these normally open into the main switch so when activated they cut power to the motor, and in return cuts power to the switched outlet which you use a small power strip to plug in the power feed motor, a router (think cutting points), and a dust collection system.

You will have to confirm your amp requirements of the switched outlet versus the equipment being used but I haven't got that far yet, I only have the power feed connected at this point. Sidebar: the keen viewer will notice the far left screw attaching the t-track is slightly lower than the others. This happened because I didn't pre-drill and the screw followed the least restrictive path and went between the tree rings and dropped about 1/8th inch. The consequence is the t-track dropped so I had to drill the holes oversize which means there is enough play in the brackets they move vertically so I can't simply just slide the brackets at will, I need to adjust them vertically also. Not a big enough issue to fix everything but the lesson learned - pre-drill!

EDIT: The wiring isn't 100% complete, I have some ideas for dust collection that will affect it so I left it as is for now.

6) E-stop switch/button

I wanted an easily accessible emergency on/off switch so I wired it in and used what I had. I ended up using a typical on/off toggle switch but added a switch extender (a trucker thing) and installed it near the area I would be when the lathe is on auto-mode. Eventually, I will add a traditional e-stop push button switch but it works as is.

E-stop switch

7) Main motor mods

I will preface this by, again, stating the motor is acquired and installed as is.

Once I started using the lathe I realized that having the switched outlet on the front of the motor, having the speed control on the back of the motor, and having the factory forward/reverse switch in a micro switch format wasn't conducive to actual use. Initially I thought by simply rotating the main box it would fix my problems so that was the first change. However, after doing that I quickly learned the speed adjusting/emergency stop lever was not just mechanical (by applying resistance to the motor) it was also electrical via a magnetic switch internally mounted. After figuring that out I relocated the magnetic switch to the the correct side and all was well. Sidebar: If you move the circuit board (mirrored image/dimensions) to the other side the magnet is no longer in the correct position and the lathe won't work - ask me how I know

After that was sorted out, I removed the forward/reverse switch (which required a small screwdriver to easily switch) and replaced it with am ON/ON toggle switch. The thought process for that was in an emergency I didn't want to have to deal with finding the middle position of a switch as it would take too long, I added a main, easily accessed, ON/OFF switch emergency switch. For general use, I mounted the original ON/OFF switch box (fuse included) to the front of the bench as it's easily accessed and easy to switch via my thumb. I also rarely change forward/reverse so that access was not required but needed.

Then I removed the speed control dial and added some wire so I could mount it on the front of the bench for ease of access. Factory dial, simply added wire. I then built a bracket to hold the speed control and forward/reverse switches.

Reversed box and empty speed switch hole:

Back of box showing new wiring and switched outlet:

Relocated power box and bracket for speed control and forward/reverse switches:

What would I do differently?

1) Move the power feed switch/control to the left with the other on/off switches for ease of access.

2) I never would've rotating the box. Considering the time I spent compared to the fact I removed the forward/reverse and speed control switches I could've easily purchased a power cord with a flush mount connector which wouldn't have been in the way and it will never be touched.

What kind of mods have you done? I'm specifically interested in dust collection for this lathe.

Last edited: