So I got the call from the machine shop today that my parts where ready and to come pick then up. I got an early start at 6am and with the help of my Dad got this beast put in place still have a lot to do.

Here is a pic of the welded then Blanchard ground steel base and table top

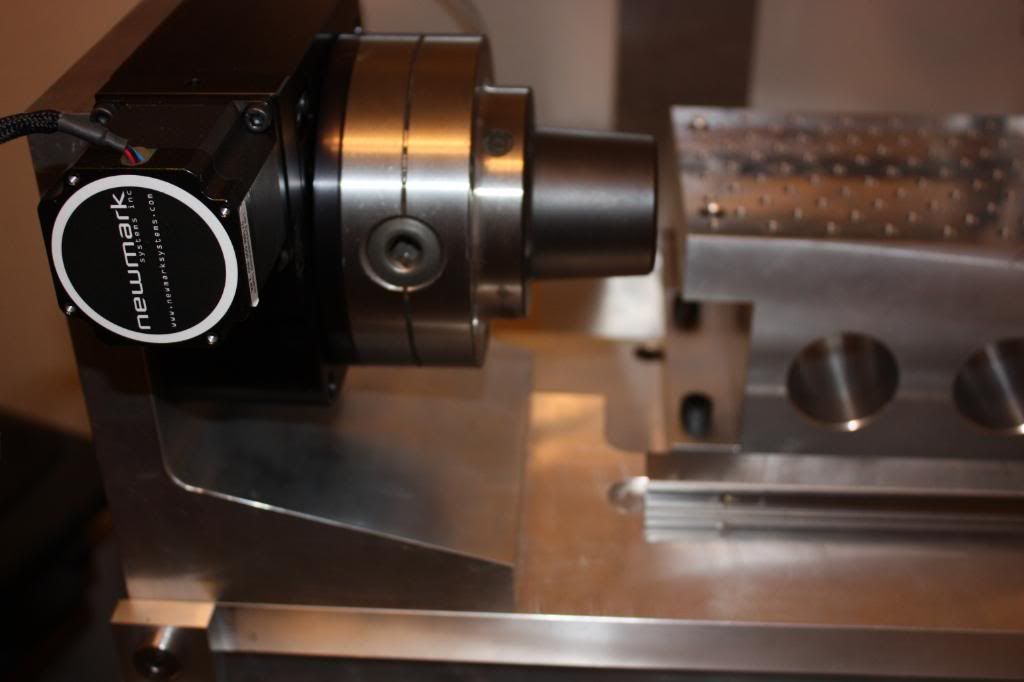

Here is the 1 inch thick Mic6 aluminum base and y axis and kerk lead screw

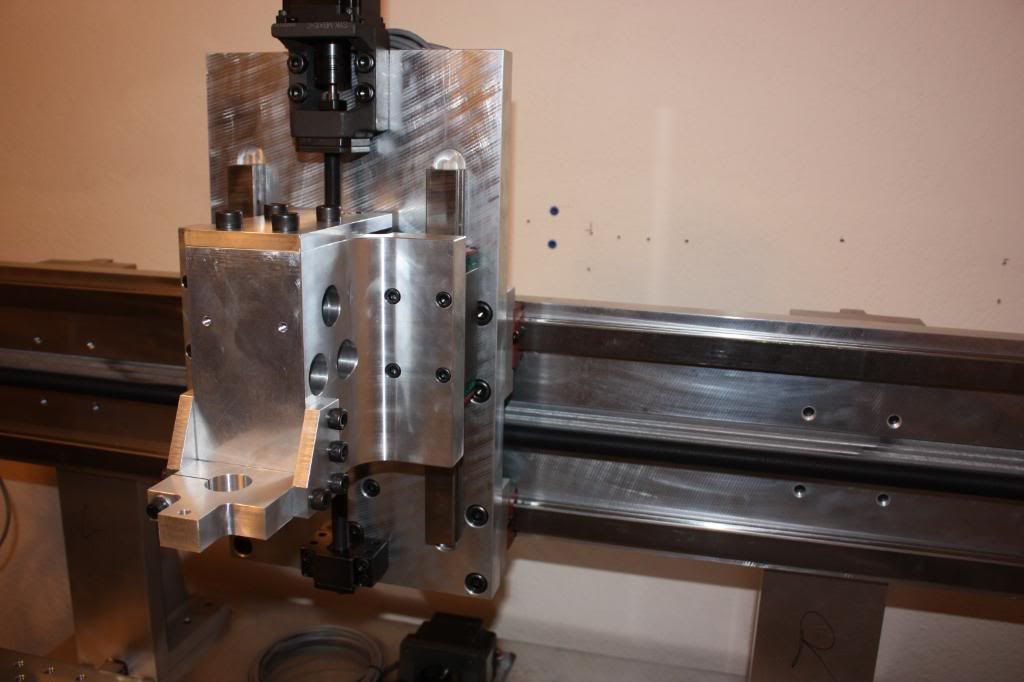

Here is the uprights and the x and z axis

Here is a pic of the welded then Blanchard ground steel base and table top

Here is the 1 inch thick Mic6 aluminum base and y axis and kerk lead screw

Here is the uprights and the x and z axis