Hi everyone.

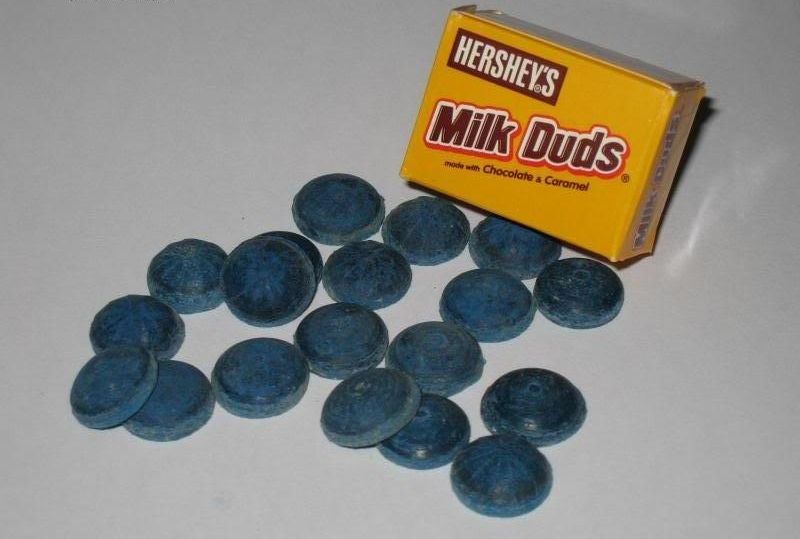

Ive had an issue getting milk duds installed. Especially on tip diameters of that of a 11.75 - 12.5mm

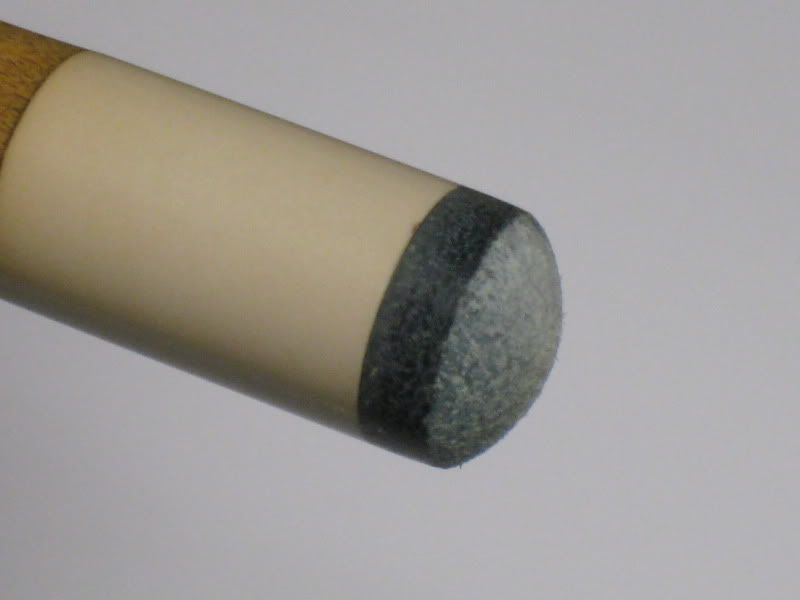

I wouldn't say it's the tip, but some have blown out when cutting them back on the lathe and i get a note saying that it couldn't be done.

Mind you there is next to no one local to me who installs tips so its not like i can shop around for a cue smith.

The last one installed on a turned down 314-2 is really flakey and I'm struggle to get the tip smooth.

Would you guys mind showing me how your milk duds look installed so I know how they should be finished?

Cheers in advance.

Ive had an issue getting milk duds installed. Especially on tip diameters of that of a 11.75 - 12.5mm

I wouldn't say it's the tip, but some have blown out when cutting them back on the lathe and i get a note saying that it couldn't be done.

Mind you there is next to no one local to me who installs tips so its not like i can shop around for a cue smith.

The last one installed on a turned down 314-2 is really flakey and I'm struggle to get the tip smooth.

Would you guys mind showing me how your milk duds look installed so I know how they should be finished?

Cheers in advance.

Last edited: