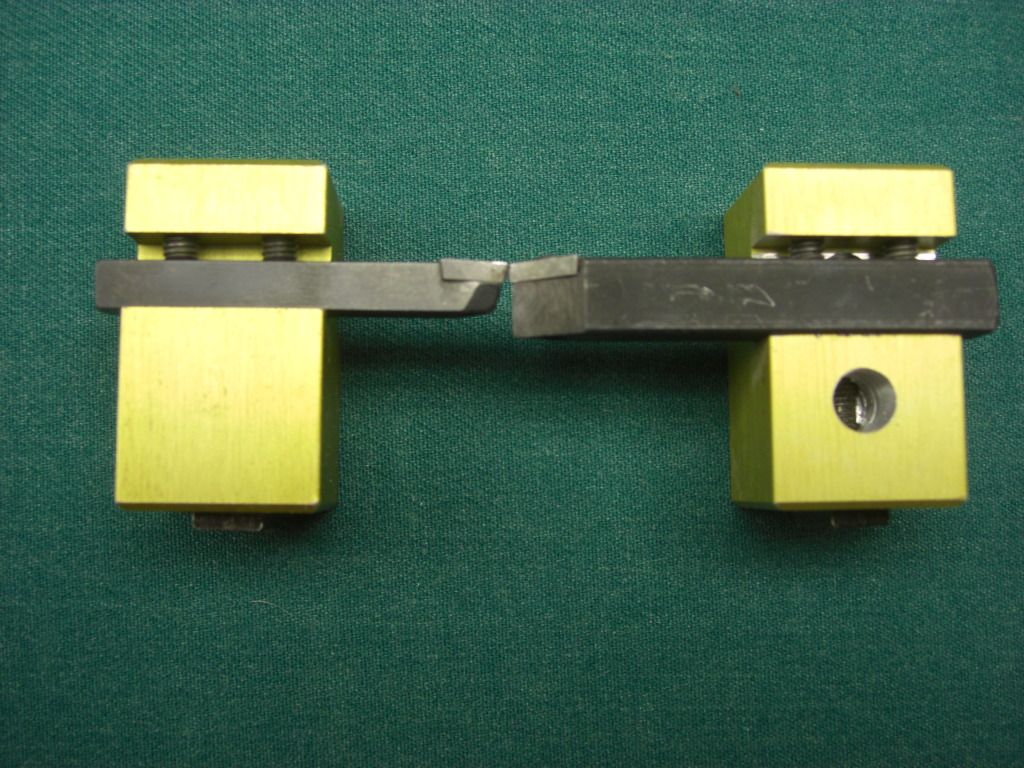

yep guys you are correct and your eyes serve you right, the cutter is 3/8 originally. To be able to use it in our holder we had to cut some flesh off the cutter so it gets lower than the center. Then we adjust the height. The cutter is on center. So that is wrong direction here, I'm more concerned if the angle is true.

Do you suggest I should turn the cutter counter-clockwise? How much? (A picture is worth thousand of words, like they say?)

The metal thing in my pics which is in the head stock is actually a dead center (chucked by the dead center end).Chuck up a dead center in the head stock. The tip of the cutter should touch the tip of the dead center.

Too much of which angle? With this single cutter we have to make two cuts: first cut the shaft/ferrule to be flat, then trim the tip side when it's glued on. As can be seen on the pictures, my priority is first angle being minimal. Which in turn makes second angle big.You do have too much angle. The cutting edge should be more square to the work piece.

Do you suggest I should turn the cutter counter-clockwise? How much? (A picture is worth thousand of words, like they say?)