O' Rings

Richard (Wolfgang) told me 3/32" x 2" o' Rings,

They are in the plumbing dept. at most hardware stores.

Mine came with 1/16...

The o'Ring grooves on the pully looks like 3/32".

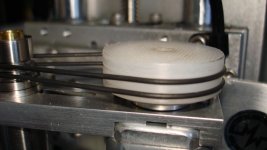

I made this larger O.D. Pully to increase the speed.

Slips on over the original pully.

Material is from a old cutting board.. UHMW in white? (Ultra High Molecular Weight)

I wanted the O.D. Larger, but, this was the biggest I could open my chuck.. mmmm

What are you guys using for belts on the Wolfgang?

Material?

ID?

OD?

Source?

Richard (Wolfgang) told me 3/32" x 2" o' Rings,

They are in the plumbing dept. at most hardware stores.

Mine came with 1/16...

The o'Ring grooves on the pully looks like 3/32".

I made this larger O.D. Pully to increase the speed.

Slips on over the original pully.

Material is from a old cutting board.. UHMW in white? (Ultra High Molecular Weight)

I wanted the O.D. Larger, but, this was the biggest I could open my chuck.. mmmm

Attachments

Last edited: