Just sucks having to wait till after my wedding.

not to mention it sets a very bad precedent! lol

Mike

Just sucks having to wait till after my wedding.

Well, in all fairness, it does work OK when you slice the tubing down one side then put it on your shaft where the wheels are going to touch, then get a strip of duct tape and go around the tubing to keep it from spinning on the shaft. that way there is no tape residue left on the shaft. I just wanted to show what would happen if people didn't read the instructions and just jump right in. The instructions DO say to use the tubing, but it didn't fit my shaft....so I improvised lol

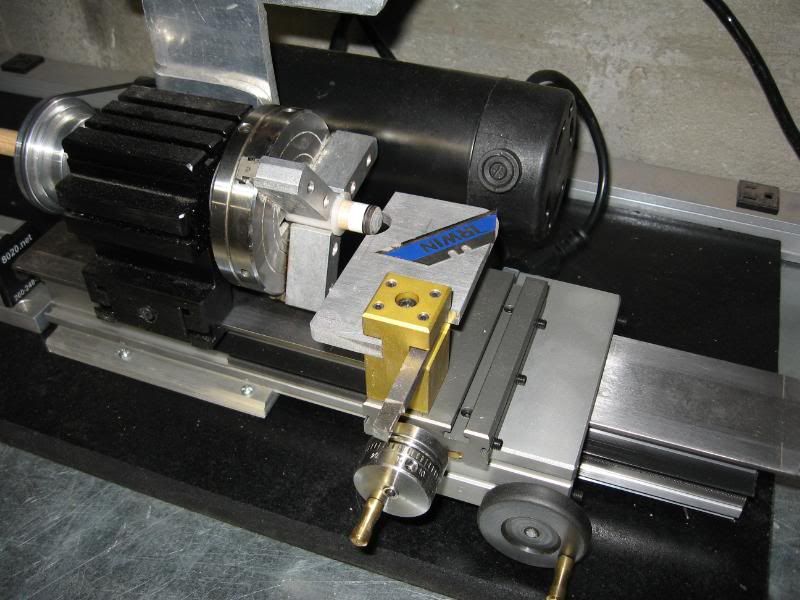

I just bought the "PORTABLE DRILL LATHE FOR POOL CUE REPAIR TIP SHAFT TOOL" for $60. I'm gonna do a full review and post pics as well. I have done a few tips in the past, I'm hoping this will make it a little easier. Now I know this isn't a lathe setup, but I just wanted something to be able to replace tips and do shaft cleaning and slicking.

So far I took it out of the box, and this is what I found out:

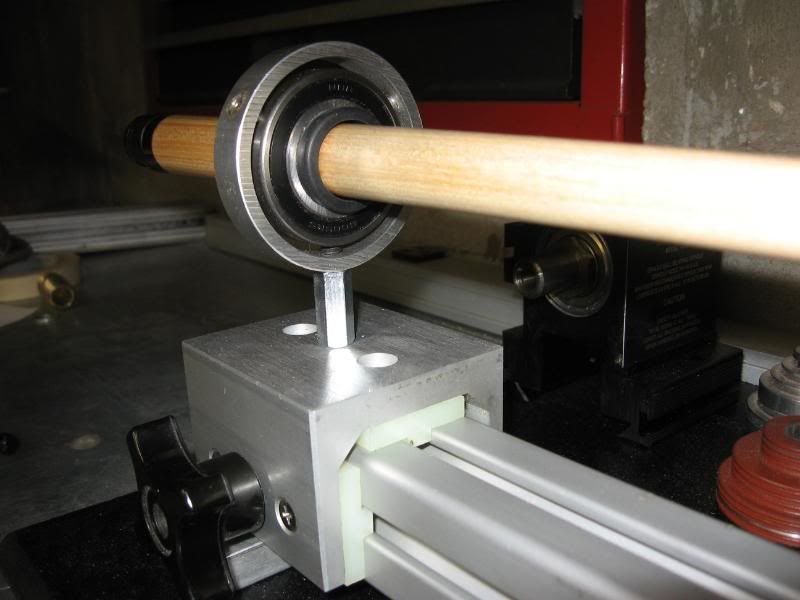

1. The steady rest seems to be a descent setup, don't like the idea of hard rubber wheels though.

2. The drill rest is just a hose clamp and is shakey at best, so I tossed it aside and am using a benchtop vise to hold the drill.

3. I bought a router speed control box for $16 from harbor frieght to adjust the drills speed accordingly

4. I'm not a big fan of the "universal arbors" but I tried it anyway. It actually worked OK and spun the shaft pretty straight. But I'll be buying the correct threaded bolts and cutting the heads off to chuck to the drill, that way I know it's centered.

5. The "collet" is just a piece of plastic tubing, didn't fit my test shaft. So I cut it down the side and wrapped a piece of duct tape around the "collet" to hold it tight. Worked good enough.

6. I wanted to see what it would do if I just used the steady rest with no collet or tape, and sure enough, it wore an indention ring in the shaft. I'll post a pic of that when I get the time to do it lol

I'll be doing a test run of it when my tips and other stuff come in. I'll post pics of the process too, start to finish, using this setup.

Anyone have any ideas on how to fix the indention that wore into my shaft? Also, what RPM should a shaft be turning to trim the tip to the diameter of the ferrule?

That looks nice! I know absolutely nothing about lathes or the parts needed to make oneI'm a noob lol I have an old drill press that I can change the rpm's with by putting the drive belt on a dif pulley....do you think that would work for a motor if I tried to build one of these. Also, what all would I need? sorry for all the questions....like i said, noob lmao Or would you be interested in selling that 1?

AMERICAN COWBOY BILLIARDS

I'm embarassed to say that I too have been burned by AMERICAN COWBOY BILLIARDS. I trusted his 99% rating and didn't look specifically at the reviews of the "cue lathe". His email messages are disgusting to those who have seen this "lathe". I will never buy anything from him again, and advise the same for all shoppers.

Donny Lutz

Author

BCA/ACS Certified Instructor 2

Has anyone else used one of the so-called Cue Lathes that you can buy from 'American Cowboy Billiards' on eBay?

I bought one of these a few months ago, and unless I have unrealistic expectations, it's the biggest piece of junk I've ever seen or used.

Does anyone else have any experience with one of these?

Just ordered one, gonna put it to the test, wanted something light weight for travel. Just to do shaft & tip maintenance, Already have large wood and metal lathes in my shop.

Glad to see you did due dilligence before buying. A wise man listens to others.

Just ordered one, gonna put it to the test, wanted something light weight for travel. Just to do shaft & tip maintenance, Already have large wood and metal lathes in my shop.