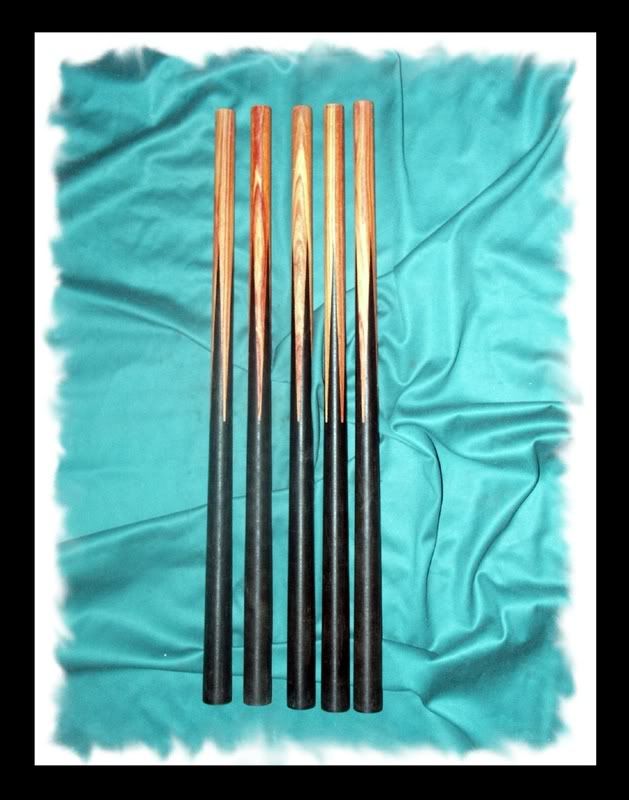

I recently acquired a 4 point purpleheart into purpleheart cue. Jerry Rauenzahn did the conversion of the John Davis blank. The cue is very forward balanced, especially with the new shaft Jerry made me for it (4.3 ounces). The cue has a 5/16x14 SS half-joint and is just hits great, extremely accurate, very solid.

My question is, when a conversion is done, is there a certain synergy that can take place between the raw material of the cue and its final construction? Can the whole be greater than the sum of its parts?

How much is the cuemaker and how much is the blank?

TIA for any input or feedback on this.

My question is, when a conversion is done, is there a certain synergy that can take place between the raw material of the cue and its final construction? Can the whole be greater than the sum of its parts?

How much is the cuemaker and how much is the blank?

TIA for any input or feedback on this.