WOW, this is getting deep.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

dedicated coring lathe

- Thread starter jecues

- Start date

Coring

Exactly. Spend a little time aligning your bearing rest, make a few collets and you are good to go.

:scratchhead: Perhaps I'm a bit dumb, but I do not understand the need for a rear chuck. It's a coring lathe. A bearing rest would suffice. Heck, if the dowels were machined to fit snugly in the bearing rest, it would be more accurate than a rear chuck, anyway. Just a simple bushing that slips on the dowel & fits the ID of the spindle would work just fine. Cue making doesn't have to be complicated.

Exactly. Spend a little time aligning your bearing rest, make a few collets and you are good to go.

Exactly. Spend a little time aligning your bearing rest, make a few collets and you are good to go.

Maybe that should be on the next coring DVD.

Last edited:

While some are mentioning using the steady rest in front of the headstock for coring, I do that all the time. But I do not hold the work piece in the steady rest. I put a collet in the steady rest that holds the end of the coring drill. It sits right in front of the piece to be cored and it eliminates any starter holes needing to be drilled or bored.

Last edited:

:scratchhead: Perhaps I'm a bit dumb, but I do not understand the need for a rear chuck. It's a coring lathe. A bearing rest would suffice. Heck, if the dowels were machined to fit snugly in the bearing rest, it would be more accurate than a rear chuck, anyway. Just a simple bushing that slips on the dowel & fits the ID of the spindle would work just fine. Cue making doesn't have to be complicated.

Exactly. Spend a little time aligning your bearing rest, make a few collets and you are good to go.

I dropped the ball on this thread so...

are you saying to cut down fronts to a certain diameter and have collets that fit over these forearms which then can slide them inside the spindle bore; then chuck up on them. This will allow the work piece to be stable and fit snug while inside the spindle to allow a straight line bore. Is that what you are saying?

I dropped the ball on this thread so...

are you saying to cut down fronts to a certain diameter and have collets that fit over these forearms which then can slide them inside the spindle bore; then chuck up on them. This will allow the work piece to be stable and fit snug while inside the spindle to allow a straight line bore. Is that what you are saying?

Well, I turn my stock round to 1 3/8" and have a bearing centered in my rest with a 1 3/8" ID. If you have an undersize, or tapered, piece a collet will take up the difference. I also use a 4 flute end mill to make entrance and exits holes about 1" deep. There is a picture on my website showing this procedure (www.denalicues.com/making a cue page 8).

I don't know about the "spindle bore" you mention. That has nothing to do with using the chuck to hold one end and the center rest the other. Some CM's have the head stock bored out smooth and insert a collet in the far end so they do not need an outboard chuck. I helped KD cues machine out his

headstock bore and it works pretty good although the custom made boring bar was expensive from Valley Tools. Of course there is more than one way to "skin the cat".

Well, I turn my stock round to 1 3/8" and have a bearing centered in my rest with a 1 3/8" ID. If you have an undersize, or tapered, piece a collet will take up the difference. I also use a 4 flute end mill to make entrance and exits holes about 1" deep. There is a picture on my website showing this procedure (www.denalicues.com/making a cue page 8).

I don't know about the "spindle bore" you mention. That has nothing to do with using the chuck to hold one end and the center rest the other. Some CM's have the head stock bored out smooth and insert a collet in the far end so they do not need an outboard chuck. I helped KD cues machine out his

headstock bore and it works pretty good although the custom made boring bar was expensive from Valley Tools. Of course there is more than one way to "skin the cat".

That's what I get for not paying attention. I though someone said they are putting the front in the spindle with a collet or maybe I read that into something.

BTW - nice web site.

and to all -- a great weekend!

I stopped boring a starter hole for the gun drill a few years ago. I made a big delrin donut to hold the gun drill while it slowly starts the hole. Saves lots of time. I got the idea from a famous person....... When I start the drill into the peice, the steady rest and the donut are almost touching the wooden dowel.

Kim

Kim

Last edited:

JC

Coos Cues

You guys inspired me to add a plate and collets to my coring chip collector box. Don't need to use a steady rest since nothing has to turn.

View attachment 413049

View attachment 413050

JC

That is like the chip box that gun drills are made for.

I surmise the ass end still gets bored to prevent blowout?

You guys inspired me to add a plate and collets to my coring chip collector box. Don't need to use a steady rest since nothing has to turn.

View attachment 413049

View attachment 413050

JC

Way too big.

That get it done for.

Got one on the steady rest too.

Less that $15 parts from Home Depot.

Coring holes

Three reasons why I pre-bore my stock prior to boring the core hole:

1. For a "starter" hole I use a 3/4" 4-flute end mill. Insures a dead center start.

2. On the exit end it eliminates blow-out.

3. When the hole has been completely bored I check to see if it bores a step

at the exit hole which would indicate mis-alignment some where in the process.

Both the pre-exit hole and the gun drill hole should be perfectly concentric with no "ledge" being apparent.

With that said there is more than 1 way to skin the proverbial cat.

Three reasons why I pre-bore my stock prior to boring the core hole:

1. For a "starter" hole I use a 3/4" 4-flute end mill. Insures a dead center start.

2. On the exit end it eliminates blow-out.

3. When the hole has been completely bored I check to see if it bores a step

at the exit hole which would indicate mis-alignment some where in the process.

Both the pre-exit hole and the gun drill hole should be perfectly concentric with no "ledge" being apparent.

With that said there is more than 1 way to skin the proverbial cat.

Although I have a nice coring set up it is my least favorite thing to do. I rate it right ahead of getting kicked in the nuts by a donkey.

Although I have a nice coring set up it is my least favorite thing to do. I rate it right ahead of getting kicked in the nuts by a donkey.

Better or worse than putting finish on cues?

harris cue comp

Banned

boring forearms

Why would you limit your lathe to a process that you do infrequently. I core about 200 forearms a year and changeover is minimal.

Good luck

Robert Harris

Why would you limit your lathe to a process that you do infrequently. I core about 200 forearms a year and changeover is minimal.

Good luck

Robert Harris

Why would you limit your lathe to a process that you do infrequently. I core about 200 forearms a year and changeover is minimal.

Good luck

Robert Harris

There is nothing like walking up to a piece of equipment, putting a work piece in it, turning it on and getting the job done without setting up each time. Granted, if you're going to do 200 at a time, then a once a year set-up is nothing. However, if you're going to core on as needed basis, then what the heck. And if you have the money, why not.

I love coring! Heck, would rather do that every day than 'finish' a cue once a week! Sure beats a kick in the nuts from a donkey.

Touche!

There is nothing like walking up to a piece of equipment, putting a work piece in it, turning it on and getting the job done without setting up each time. Granted, if you're going to do 200 at a time, then a once a year set-up is nothing. However, if you're going to core on as needed basis, then what the heck. And if you have the money, why not.

I love coring! Heck, would rather do that every day than 'finish' a cue once a week! Sure beats a kick in the nuts from a donkey.

Touche!

If you have all the money and room in the world to spend on cuemaking equipment, then that is great. HOWEVER, it takes me about 10 mins to setup my main lathe to core.

I DO have a second lathe I bought for coring though, for 1000.00. The argument has been made that buying a new Grizzly is the way to go because of support and parts. That's all well and good, but most of the issues with lathes are documented and it's worth 2000.00+(to me at least) to do some research and buy accordingly. The WORST mistake I EVER made was buying from a dealer. It's a nice(Microweily) 1340, but the guy was/is a dick. I didn't do enough research and overpaid. The NEXT day a Clausing Colchester 1340 came up for the same price. Point is, I should have waited and done more homework.

As far as parts? They CAN be a pain, BUT there are some stocking warehouses in the USA besides Grizzly. Chinese/Taiwan lathes, in general, have 80% of the same parts. Standing side by side only the bed is different between my Lux Matter and Morton Fel. The gears, lights, levers, threading....even the cover plate on the head stock is exactly the same.

Unless you buy a Sharp or a used Clausing, there's nothing that special about any of them and the ones that have issues can be avoided. None of the 3 lathes here have anything that was scraped, except for the underside of the tailstock and maybe a gib. It should also be noted the the Fel and Lux were high end Taiwan lathes and about 10k new.

If you find a Lux, Morton, Fel, I'll send you any mechanical parts you might need. I got ill when I dismantled the gear box, as it looks brand fricken new... The ONE problem, and it's a beyatch, is the cross slide bearing/wheel assembly where the housing that supports the near side of the the lead screw is mounted to the saddle. It's poorly machined and a bad match. This is only an issue if something happens(like having the damn lathe fall over) and you need to replace it. Neither of the replacements fit properly, nor could I modify them enough to make them work. The holes in the housing don't match up just right with the saddle and the surrounding metal is thin. It's obvious the casting/machining was screwed up from the get go and never addressed or I was just sent NOS parts left over before the fix.

Last edited:

Buy them on credit then move to Florida.If you have all the money and room in the world to spend on cuemaking equipment, then that is great. HOWEVER, it takes me about 10 mins to setup my main lathe to core.

I DO have a second lathe I bought for coring though, for 1000.00. The argument has been made that buying a new Grizzly is the way to go because of support and parts. That's all well and good, but most of the issues with lathes are documented and it's worth 2000.00+(to me at least) to do some research and buy accordingly. The WORST mistake I EVER made was buying from a dealer. It's a nice(Microweily) 1340, but the guy was/is a dick. I didn't do enough research and overpaid. The NEXT day a Clausing Colchester 1340 came up for the same price. Point is, I should have waited and done more homework.

As far as parts? They CAN be a pain, BUT there are some stocking warehouses in the USA besides Grizzly. Chinese/Taiwan lathes, in general, have 80% of the same parts. Standing side by side only the bed is different between my Lux Matter and Morton Fel. The gears, lights, levers, threading....even the cover plate on the head stock is exactly the same.

Unless you buy a Sharp or a used Clausing, there's nothing that special about any of them and the ones that have issues can be avoided. None of the 3 lathes here have anything that was scraped, except for the underside of the tailstock and maybe a gib. It should also be noted the the Fel and Lux were high end Taiwan lathes and about 10k new.

If you find a Lux, Morton, Fel, I'll send you any mechanical parts you might need. I got ill when I dismantled the gear box, as it looks brand fricken new... The ONE problem, and it's a beyatch, is the cross slide bearing/wheel assembly where the housing that supports the near side of the the lead screw is mount to the slide. It's poorly machined and a bad match. This is only an issue if something happens(like having the damn lathe fall over) and you need to replace it. Neither of the replacements fit properly, nor could I modify them enough to make them work. The holes in the housing don't match up just right with the slide and the surrounding metal is thin. It's obvious the casting/machining was screwed up from the get go and never addressed or I was just sent NOS parts left over before the fix.

OJ Simpson style after he lost his civil case. Oops!

If you have your lathe set up like Kim does then I think set up time for coring is less than set up time to put a joint in a butt. I don't see set up time as being an issue if your lathe is set up right for easy changeover.

Now if you want to talk about building full splice cues now there is something I wish I could keep machinery set up for.

Now if you want to talk about building full splice cues now there is something I wish I could keep machinery set up for.

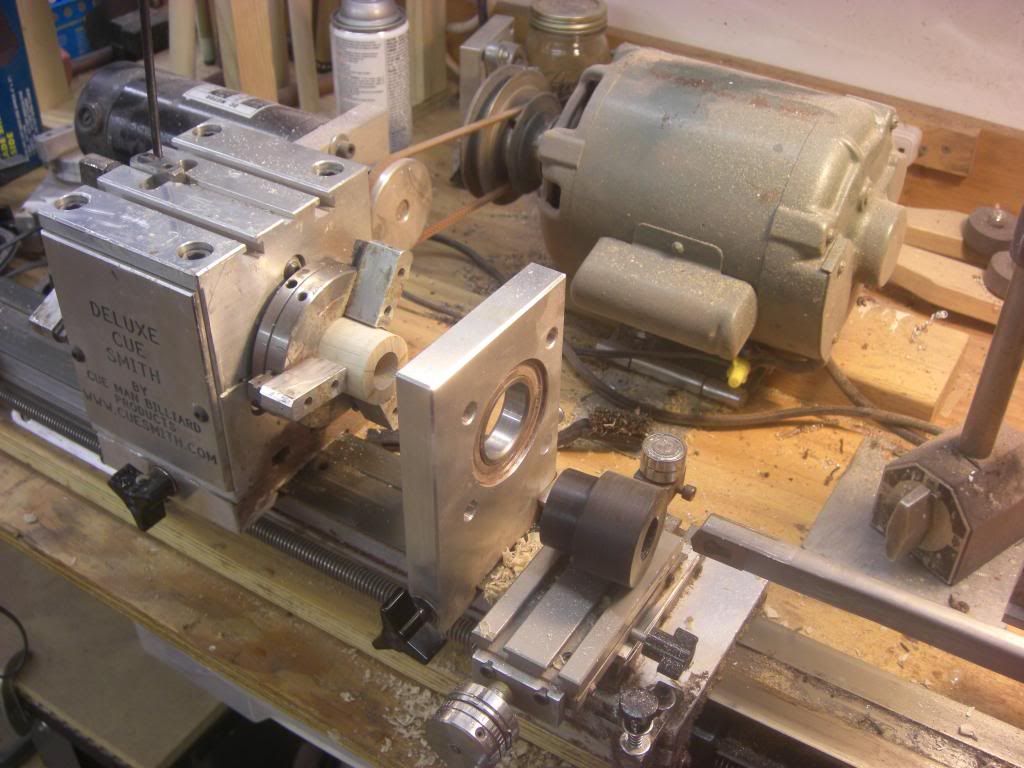

![001 [800x600].JPG 001 [800x600].JPG](https://forums.azbilliards.com/data/attachments/300/300799-57217e6aa318ad55d722de6d103ab893.jpg?hash=VyF-aqMYrV)

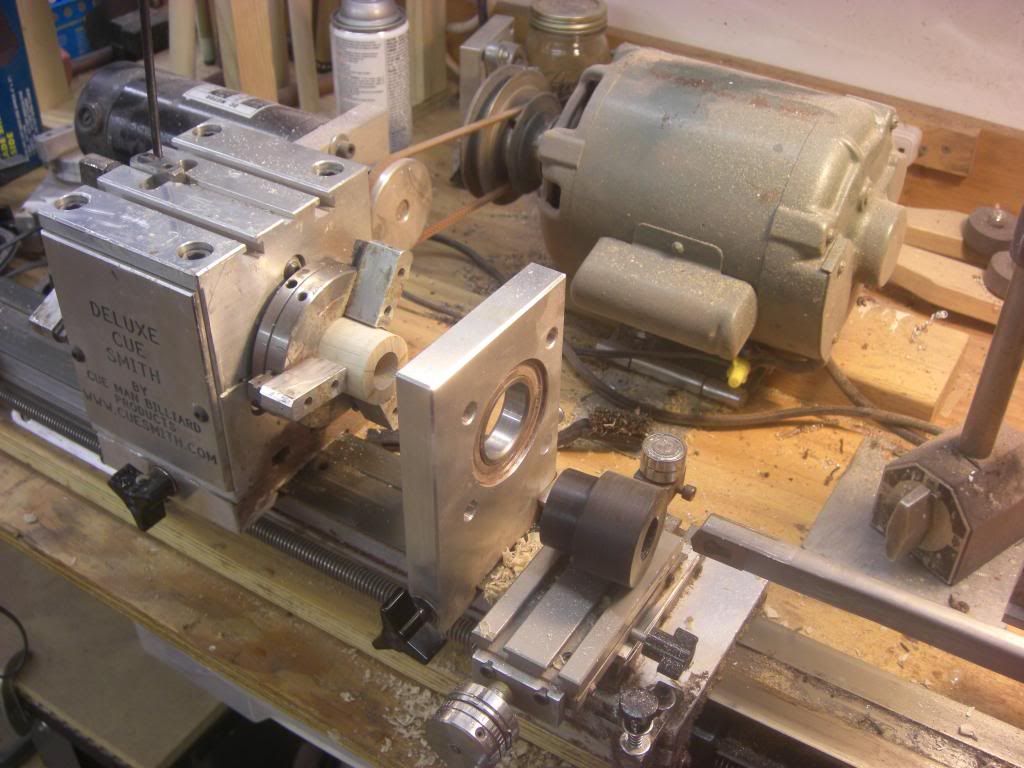

![002 [800x600].JPG 002 [800x600].JPG](https://forums.azbilliards.com/data/attachments/300/300800-de7845b70de20c68cadeeaf17c0c226b.jpg?hash=3nhFtw3iDG)