Hey folks,

Just wanted to share with you guys my project for the last couple of weeks.

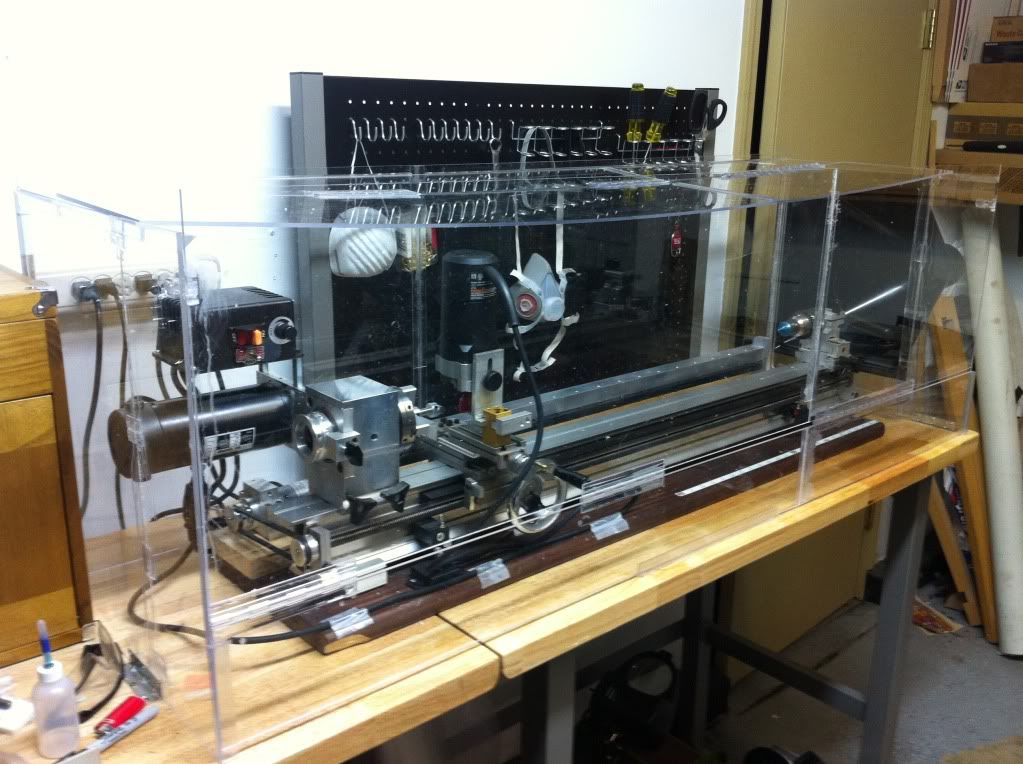

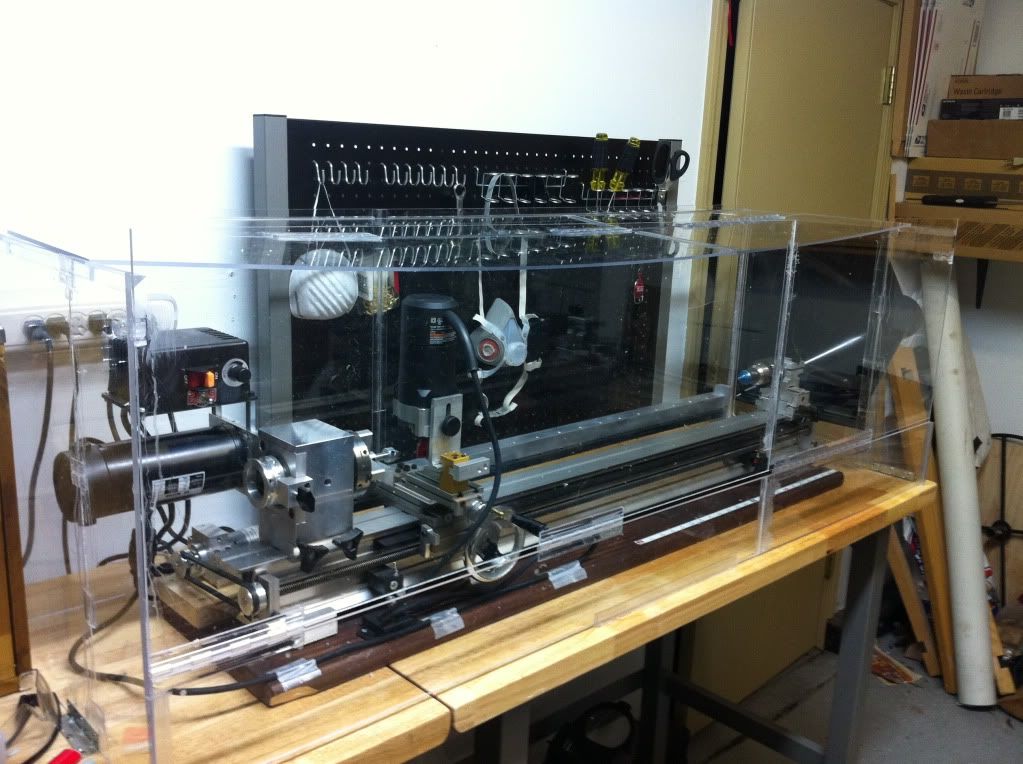

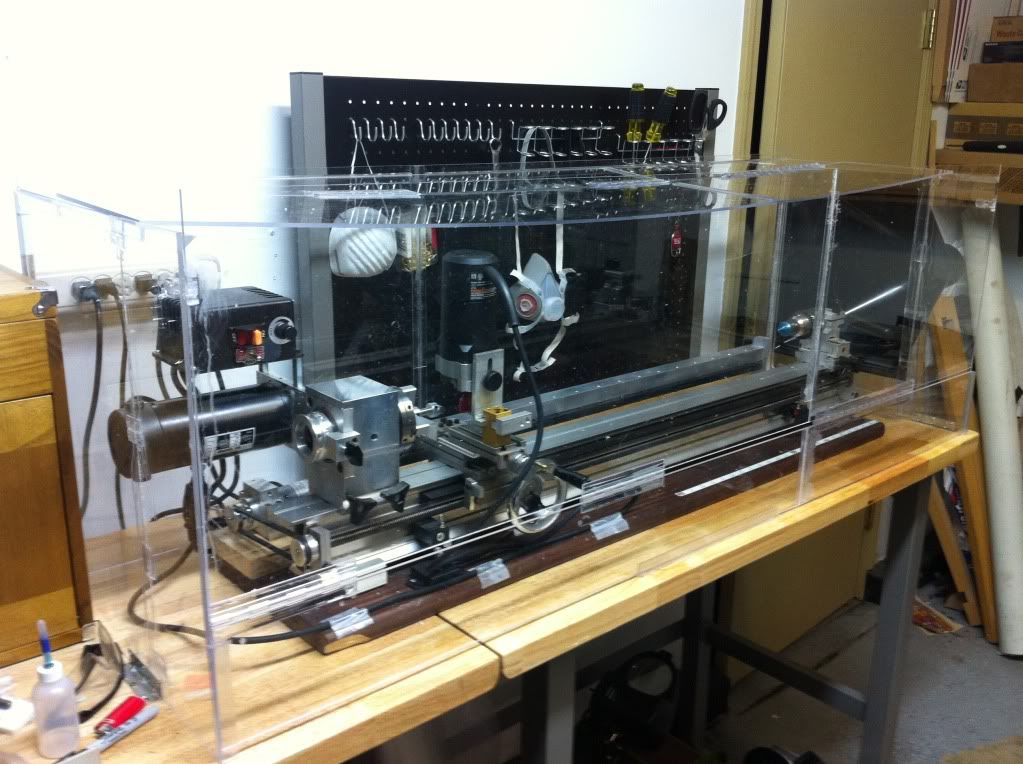

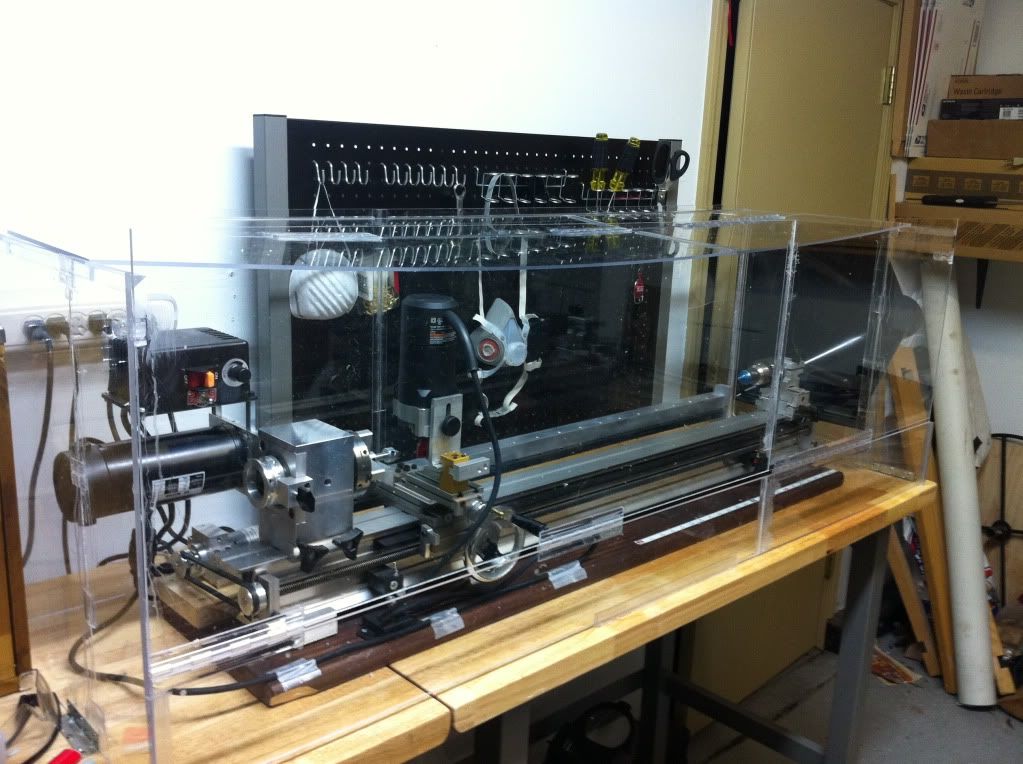

Trying to contain dust and have it sucked up, at least most of it.

Made out of plexi-glass from TAP Plastics, about $150.00... Plus a few more things I did not measure right and some accessories, I would say the project is about $200.00 now.

I have a Delta 1HP Dust Collection system, might not be enough power but was all I could afford right now, off of Craigslist for %150.00 and was like new - like new the Delta is not far from $400.00.

Anyway, still needs a few tweaks on the top cover that will be done later in the week.

You can use this setup with any Hightower Lathe, Custom Cue Lathe or other similar bench top cue lathes.

My father in law helped me a bit on this project as well :thumbup:

A big thank you for the advice from my friend Jacob AZ'er LGSM3. I know the idea is not new, but I did it on my own.

Just wanted to share with you guys my project for the last couple of weeks.

Trying to contain dust and have it sucked up, at least most of it.

Made out of plexi-glass from TAP Plastics, about $150.00... Plus a few more things I did not measure right and some accessories, I would say the project is about $200.00 now.

I have a Delta 1HP Dust Collection system, might not be enough power but was all I could afford right now, off of Craigslist for %150.00 and was like new - like new the Delta is not far from $400.00.

Anyway, still needs a few tweaks on the top cover that will be done later in the week.

You can use this setup with any Hightower Lathe, Custom Cue Lathe or other similar bench top cue lathes.

My father in law helped me a bit on this project as well :thumbup:

A big thank you for the advice from my friend Jacob AZ'er LGSM3. I know the idea is not new, but I did it on my own.

Last edited: