Hello, I would like to ask your help on how to set up for threading

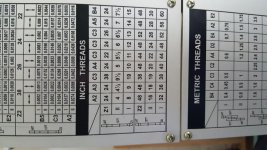

Mainly 5/16 18 for ferrule tenon and 3/8 10 for shaft thread and joint....too many knobs ... I never done this before... this is my lathe set up... thanks in advance. ...

Mainly 5/16 18 for ferrule tenon and 3/8 10 for shaft thread and joint....too many knobs ... I never done this before... this is my lathe set up... thanks in advance. ...