How is the wood for a shaft blank cut out of a tree trunk? Is the wood taken from a slice that is perpendicular to the trunk or from wood that runs parallel? If it is perpendicular does a 29" shaft come from a tree that has a diameter of 30 to 32 inches or from one that is at least 60 inches? If perpendicular do the blanks radiate from the center or do they just make the circular slice into a 29 in square and cut as many as they can from that square?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How Are Shaft Blanks Cut From Trees?

- Thread starter TheBook

- Start date

Short and Sweet:TheBook said:How is the wood for a shaft blank cut out of a tree trunk? Is the wood taken from a slice that is perpendicular to the trunk or from wood that runs parallel? If it is perpendicular does a 29" shaft come from a tree that has a diameter of 30 to 32 inches or from one that is at least 60 inches? If perpendicular do the blanks radiate from the center or do they just make the circular slice into a 29 in square and cut as many as they can from that square?

The the is logged.

The bark is removed.

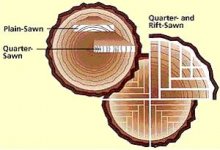

It is then "Quarter-Sawn", which would be sawing the log into 4 pie shaped pieces.

Then the Pie Shaped pieces are cut into boards. After one board is cut, the Pie Shaped piece is "flipped over" and a board is cut from the other side. Then again and again and again, until there is nothing left.

Then those boards are placed in a Kiln to dry.

Then they are cut into 4/4 squares or larger.

Then they are turned round.

Then they are cone tapered.

Then they are "pro-tapered" (whatever that is supposed to mean

And then you have a shaft blank.

BiG_JoN said:Short and Sweet:

The the is logged.

The bark is removed.

It is then "Quarter-Sawn", which would be sawing the log into 4 pie shaped pieces.

Then the Pie Shaped pieces are cut into boards. After one board is cut, the Pie Shaped piece is "flipped over" and a board is cut from the other side. Then again and again and again, until there is nothing left.

Then those boards are placed in a Kiln to dry.

Then they are cut into 4/4 squares or larger.

Then they are turned round.

Then they are cone tapered.

Then they are "pro-tapered" (whatever that is supposed to mean)

And then you have a shaft blank.

Or, in other words, parallel.

Tracy

BiG_JoN said:Short and Sweet:

The the is logged.

...

I think your explanation is incomplete. Where does the tree come from Daddy????

Big Jon

Thanks for the great explanation and time it took to write it.

Some shafts are better than others and a lot has to do with the wood. Some wood is old growth, and some has straight and tighter grain. Is the wood that comes closer to the core better than wood that is from the edge and what about being closer to the base? What makes a piece better for a good shaft?

Thanks for the great explanation and time it took to write it.

Some shafts are better than others and a lot has to do with the wood. Some wood is old growth, and some has straight and tighter grain. Is the wood that comes closer to the core better than wood that is from the edge and what about being closer to the base? What makes a piece better for a good shaft?

A

Arnot Wadsworth

Guest

BiG_JoN said:Short and Sweet:

The the is logged.

The bark is removed.

It is then "Quarter-Sawn", which would be sawing the log into 4 pie shaped pieces.

Then the Pie Shaped pieces are cut into boards. After one board is cut, the Pie Shaped piece is "flipped over" and a board is cut from the other side. Then again and again and again, until there is nothing left.

Then those boards are placed in a Kiln to dry.

Then they are cut into 4/4 squares or larger.

Then they are turned round.

Then they are cone tapered.

Then they are "pro-tapered" (whatever that is supposed to mean)

And then you have a shaft blank.

I agree that it should be done that way but most shaft wood is not quarter-sawn it is flat sawn because it is much cheaper to flat saw.

Straightness or grain tightness are not as affected as much as growth rings and ring direction, not sure if you saw the photo of how a quatersawn piece of wood is cut, if you look at it you will see how a square will have more rings and they usually run straight through the shaft instead of across it.

This is especially true when the dowel originates from the end of a flat sawn board.

Mike

This is especially true when the dowel originates from the end of a flat sawn board.

Mike

One thing that hasn't been mentioned is a cuemaker should take the time and liberty to personally select and check each board he'll use for shafts... hit some miss some... then when you star cutting the boards down to squares hit some and miss some more... when the whole cutting thing ends you'll be surprised just howmuch you end up with... then the turning begins... and you'll be surprised again how much you're left with

Hadj

Hadj

Any more depressing stories bud?hadjcues said:One thing that hasn't been mentioned is a cuemaker should take the time and liberty to personally select and check each board he'll use for shafts... hit some miss some... then when you star cutting the boards down to squares hit some and miss some more... when the whole cutting thing ends you'll be surprised just howmuch you end up with... then the turning begins... and you'll be surprised again how much you're left with

Hadj

And people ask why good shafts cost over $125 now.

JoeyInCali said:Any more depressing stories bud?

And people ask why good shafts cost over $125 now.

One time I was in the middle of coring an ebony half way into the piece... then my girl called... went back an hour later, the dam hole wasn't straight anymore,

From that day on, no more call during coring!

Purdman

Banned

Why?

I have old cues from the 60's and 70's. The shafts are still straight. I am talking about Adams, Scruggs, Phillippi, etc. These old shafts are straight as an arrow. My newer cues shafts have a little wobble to a 1/4 in. wobble. Why are the shafts from the older cheaper cues (Adams) straight and some of the newer ($5,000 and $6,0000 cue shafts) not straight. Explanation please!!!!

Don

I have old cues from the 60's and 70's. The shafts are still straight. I am talking about Adams, Scruggs, Phillippi, etc. These old shafts are straight as an arrow. My newer cues shafts have a little wobble to a 1/4 in. wobble. Why are the shafts from the older cheaper cues (Adams) straight and some of the newer ($5,000 and $6,0000 cue shafts) not straight. Explanation please!!!!

Don

Quarter sawn may make it easier to pick out your boards because you can see how many growth rings and how straight they run over the whole piece rather than just its edges. But I fail to see how it makes any difference how the boards were cut once it is a 1" square.Pancerny said:It is also more expensive to purchase quarter sawn wood because there is a lot more waste...and I mean a LOT more....but it is the better way to cut wood in general. It also usually means more growth rings in the shaft dowel.

Mike

Quartersawn vs. flatsawn sure makes a difference for furniture building when the wood is predominately wide and flat. The show surface of the wood will look completely different for the two types of sawing.

But when the wood is square or round, there will be two flatsawn faces, and two quartersawn faces. And each of the two sets of faces will be the same size (becasue its square). The end product (a round dowel) seems the same in both cases. It doesn't matter how the wood was cut initially.

Or does it? Please clarify how it would make a differnece for the finished round product?

Thanks.

But when the wood is square or round, there will be two flatsawn faces, and two quartersawn faces. And each of the two sets of faces will be the same size (becasue its square). The end product (a round dowel) seems the same in both cases. It doesn't matter how the wood was cut initially.

Or does it? Please clarify how it would make a differnece for the finished round product?

Thanks.

Whether a shaft came from a flatsawn, quartersawn, rift cut, face cut, or any other type of miling makes no difference once the shaft has been turned round. Although it will make a difference to furniture makers and other woodworkers.

Scott

Scott

Donald A. Purdy said:I have old cues from the 60's and 70's. The shafts are still straight. I am talking about Adams, Scruggs, Phillippi, etc. These old shafts are straight as an arrow. My newer cues shafts have a little wobble to a 1/4 in. wobble. Why are the shafts from the older cheaper cues (Adams) straight and some of the newer ($5,000 and $6,0000 cue shafts) not straight. Explanation please!!!!

Don

well to make a long story short the wood available isnt as good as back then

the trees back then grew in the forest competeing with other big trees for water and sunshine , they grew slower and more dense

much of the wood being sold now is from trees that were planted on the

bare ground after they went through and harvested all the timber

those seedlings grew very fast due to no other big trees blocking sun and

sucking all the nutrients and water from the soil