You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

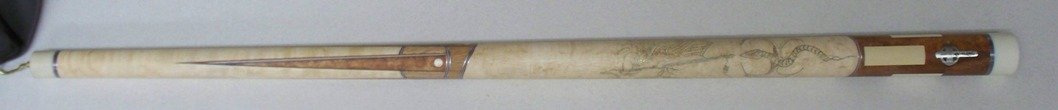

New cue ... new way to look at 4 points...

- Thread starter Piercyexclusive

- Start date

Quite interresting. I applaud your out of the box thinking. I like the last one best. Keep up the good work.

Mr H

Thanks got one more to show in a few hours doing the last touch up on it

Piercyexclusive, sent you a PM

as for the angles I already thought of the sliding and the angles will not move I have secured them not just with a core but by other interior means ......... as far as strength of the cue I think it's strong enough. Miter hand saw not electrical saw..... they were cut on a jig with a miter HAND saw cause there seems to be more glue lines with a miter(electrical) saw and as far as a mill goes I don't have the means to use one of those yet.hand saw with a few minutes of sanding = less glue visibility

I had figured as much.....good choice on hand mitering.

The problem with an electric miter saw is that the blade has some run out on the tip....it wobbles somewhat left to right as it spins.....

POSSIBLY you could try it with a much smaller blade i know they make down to at least a 5 3/8" blade....if you can fit it to the saw, with a smaller blade you could possibly attain the higher tolerance you need.

If you could make a milling attachment for your lathe you could build a taper bar that would let you chuck up on center and make that slanted cut with a router precise and in a more timely fashion.

Don't Forget about a bandsaw either.....you could build a miter jig for the bandsaw....that would probably be the tripple nutz for what your doing there. Hell if you can build points on one I'm sure it wouldn't take long to figure out a jig to accomplish that cut.

Last edited:

Being a member of the ACA isn't always a good thing.............from what I've heard.

Good luck, and keep the love for what you're doing. That alone will result in a superior product that sombody will buy.

dave

Good luck, and keep the love for what you're doing. That alone will result in a superior product that sombody will buy.

dave

I am glad to see someone interested in doing some new designs.

I am sick to death of the same old traditional copy of a copy of a copy.

Keep looking for a new way to approach cuemaking.

Sincerely,

Bill Stroud

Josswest

Not to put you on the spot...or "inlay"....or anything...but the vibe I am getting from this thread is that he is learning as he goes and adding equipment as he goes.....

I know you guys don't like to give away trade secrets and such...but wouldn't it be nice if this (obvious) young talent got to meet and "workshop" with a legend in the cue building business.....I wonder what that would produce???????

Not to put you on the spot...or "inlay"....or anything...but the vibe I am getting from this thread is that he is learning as he goes and adding equipment as he goes.....

I know you guys don't like to give away trade secrets and such...but wouldn't it be nice if this (obvious) young talent got to meet and "workshop" with a legend in the cue building business.....I wonder what that would produce???????

I appreciate what you said and you know I have in the past tried to talk to a few people about this "working and learning and giving" but again and again I was never distinguish enough for them. The my ideas were to radical. then I haven't been in business long enough. I even called some of them to just ask basic questions and left messages they never returned one call I made...... well only one .... jim buss. but a very brief conversation that added to my inspiration that my dad had given me; to do things my way. but should someone want to collaborate with me, man. that would be awesome. I would be humbled by any offer.

So, how much are these two cues? I haven't read the whole thread, so you may have already answered this, but... what joint do you use or are there options?, what are the measurements (0.xx") at the joint the butt?, how much do they weigh?, are the shafts maple?, what ferrules (if any)? are you selling them locally? Very creative functional art here, thanks for sharing.

Very nice! I like the addition of the inlays. Unique look. I really enjoyed talking with you this evening. I am excited about the opportunity to own one of your works of art! Fantastic work. Looking at your pictures I really like the point design on the bottom pictures of your 12:32PM post (2nd prototype pics) and the last ones you just posted at 10:19PM.

Thank you for answering my questions earlier.

For those going through this thread, know that this guy will answer any question you have. Fantastic personality and focused on what he does - which is create some outstanding and unique custom cues!

Thank you for answering my questions earlier.

For those going through this thread, know that this guy will answer any question you have. Fantastic personality and focused on what he does - which is create some outstanding and unique custom cues!

RunoutKing

Registered

I like the way that looks. It's different from all the other cues out there and I always like originality.:thumbup:

So, how much are these two cues? I haven't read the whole thread, so you may have already answered this, but... what joint do you use or are there options?, what are the measurements (0.xx") at the joint the butt?, how much do they weigh?, are the shafts maple?, what ferrules (if any)? are you selling them locally? Very creative functional art here, thanks for sharing.

tell me what you want.....what you ask for is what you will get. ex.....what joint size do you want? what joint do you want? what type of shafts do you want? what pin do you want? what weight would you like? what ferruls do you want?

I am a custom cue maker I'll do what you would like me to do.

this is some really great work...

you have any with an angled joint collar, or shafts where the collars are angled as well?

I can make what you want...:wink: if interested feel free to call If not here leave a message with a good time to call. thanks

Marshall

MitchellThomas

Registered

its about time great design

got some pics of the cues that I am building for a couple of people who bought a cue from me.......will be posted tonight. and for those who will be there at the gem city classic to see my cues and test it pm for a # to call me at so that you can call when you get there and want to meet up. this is also so that I make sure everyone who wanted to test the cue out can before I give them to the respective owners on the 11th. what I bring will most likely be the ones that will be going out. can only make so much in so little time.....wish I had more of it. thanks.