There is a lot of information about powerfeeds and specialized products from Thomson. That said they are not cheap solutions. I have a Acme screw coming and will mount it with an inline motor, there are lots from Dayton.

I will power the motor with a Tattoo power source control with a 3-12 volt smooth adjustment variable speed (no clicking into different speeds)it should work well, just trying to figure how fast the carriage will travel. If the screw is 12 tpi and the motor turned at 100 rpm that is about 8 inches in a minute, seems about right. A 30 inch pass would take about 4 minutes. Maybe I need a little faster. I had a pinion driven feed that engaged the rack and it seemed to take 5 minutes to travel down the length of a cue, and get a clean cut. Any faster wasn't great results. I never had a 6 blade bit, they must be alot better that a standard 2 sided bit. I have a feed nut coming that I will mount to a bracket. Another bracket will face up to the leadscrew one and be joined with a couple threaded knobs. This way the bracket can be run down to the far end when not tapering and the normal carraige knob used to move it. I may add in a length of 8020 aluminum slotted square stock with a linear bearing for the leadscrew bracket to ride in. It may lend stability and keep the travel inline. They provide minimal resistance, and 8020 will not flex. Then again the screw is sturdy enough not to flex much over a 36-40 inch run.

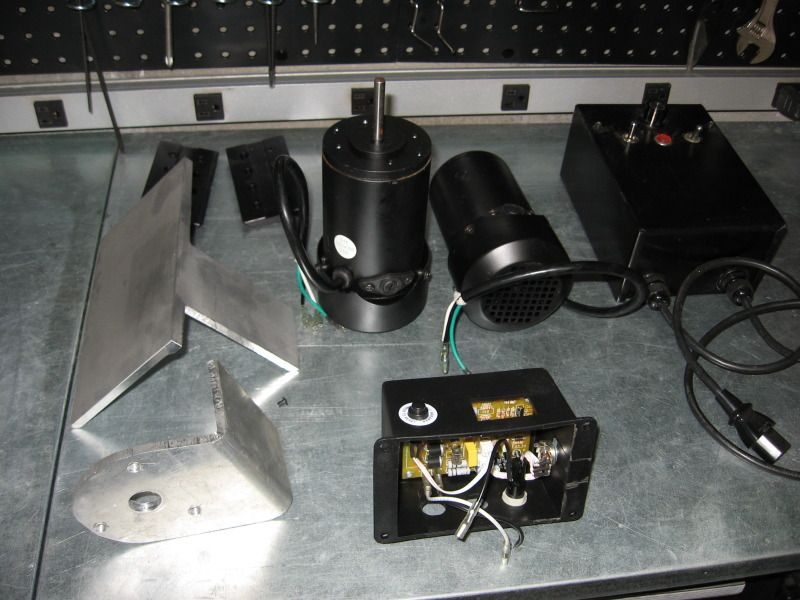

Please post photos of your designs, let me know what motor chices are best for this type of setup. Shouldn't need a ton of power, to move the bit through the work.

For a motor I want it to be adjustible speed and revisible. I dont want a Marathon mutliple pully speed adjustment type setup. I want to mount the motor on the headstock, so it's easy to slide it around the bed.I think 1/2 hp is required for a tapering cuebuilding lathe. I really don't want to have trouble wth boring with a 1/3. So he Penn State 1/2 is agreat price at $110 with control box, it lacks a reverse swith, but easy to add. I see a nice little machine shop motor that is 1/3 hp, has a control box with variable speed and reverse. I have been told the control box is superior to the Penn State. I found a jet lathe motor pretty pricy, bigger 3/4 and 1 HP motors, but no controls. Leaning towards the ease of the Penn State, 1/2 hp and inexpensive, if there were issues I could swap it out, they are widely available.

If you have opinions on motors or suggestions on different ones to consider please let me know.

I have some nice components coming, now I have to power this monster and set up the controls so everything works together well.