If you are going to make a claim that something is 'just sound engineering', then prove it. That is what engineers do. They design using known mathematical and physical theories/laws.

Until someone can show me a proof that I cannot refute, then it actually is a marketing fairytale.

Justify any shite that you want to use in whatever way you want, but if you say it is 'engineered' or is better, then be prepared to prove it.

dld

DD,

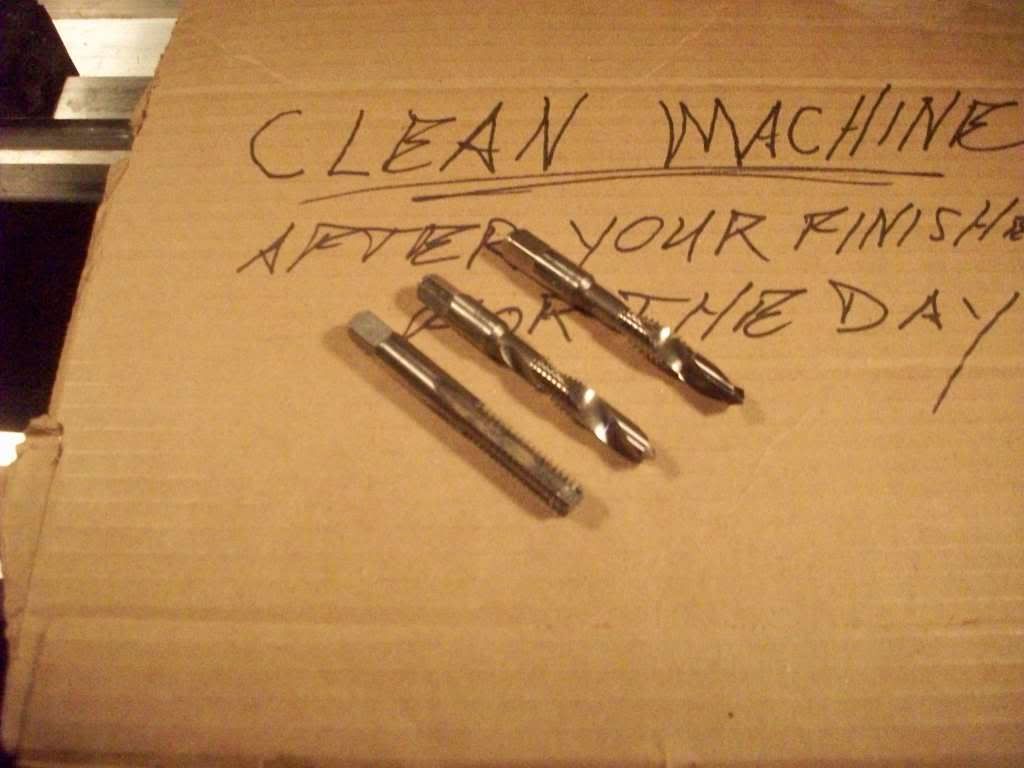

The engineers design the taps and I only use them. I can only control the insert material selection, minor size and embedment length.

I never said better. Just a sound practice I took from Ray Schuler's philosophy or play book. Ray was a graduate engineer and learned the art of building cues from Herman Rambow. He also built cues for 40 years and had an impressive list of world champions who used his cues exclusively including Raymond Cuelemans. His example and advise is something that I miss and surely valued.

Maybe I should have chosen my words better to get a point across. I think that Mezz makes a very good cue and would never say anything bad about their new joining system as I don't have any experience with it. I would like to know more about it however. I would never bash anything without observational experience. That's only fair.

There are different reasons that people use a non standard pin ( not just marketing ) and I was just pointing out my tapping method for an example concerning the subject and the way this thread was going.

I am sure that when Bill Stroud introduced his radial pin concept he had some nay sayers at the time as has been implied here about the Mezz pin. Only time will tell.

Also mechanical torque specifications for threading metals does not apply to threads cut in wood or phenolic insert materials with reference to thread degradation issues that would be applicable in this case.

If people don't try different things in a discipline, progress or improvement opportunities vanish. There is a reason why most CMs are not using an Acme thread anymore.

No one here is going to change their way of doing things because of my post for sure nor was that my motivation. I just wanted to share a point of view and one method or way of getting a job done with a different twist and a desirable outcome. IMO. There a many ways to skin a cat however.

I can tell you this, as someone who has bought a few custom cues in my day and one who builds and sells custom cues, that no one wants to buy a cue that when they screw it together it feels loose until it faces. This has been my observation in this area. Right or wrong, perception is reality and a tighter fit is more desirable to a player. The facing is paramount of coarse. If your concentricity is spot on there is no reason why you can't have a tight threaded fit and great facing.

If you are building cues for players this is something that is important that people do care about.

IMO, "who cares" and cue making should not be in the same sentence if you are putting your name and product out there. Every feature element and every tolerance detail is paramount and very important to the serious cue maker.

Rick

Who cares if you can move the shaft sideways when it isn't tight? The AXIAL force in the joint creates the forces on the joint face to resolve the moment (I'll assume you know the engineering definition of 'moment' or will look it up) created when hitting a ball.

dld