JC

Coos Cues

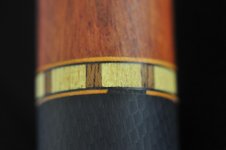

I recently acquired a veneer ring punch from Deco and this is the first cue I tried it on. Fortunately this cue is being built as a father/daughter project with my 5 year old. She picked out every part of it from the wood pile. The butt sleeve is bloodwood (handle paduak) and the cap is juma. There are 2 .015 black fiber rings outside the stitch ring. I am trying to figure out what happened to the orange veneer ring. There are 6 other ones on the cue that look fine. I took the first rough cut and noticed it and now I have cut it down to final size hoping to find that missing orange spot. So I guess it's going to remain a flaw on this cue when she hands it down to her grand daughter some day.

But I'm trying to figure out what went wrong so I don't do it again. I glued it with west systems and a clamp putting the final rings on along with the cap after I faced the sleeve which I glued on first. I don't think it broke out when I slid it together but I'm not sure why it would be solid black in there instead of clear epoxy if it had. Any tips on using veneer rings would be appreciated.

Thanks,

JC

But I'm trying to figure out what went wrong so I don't do it again. I glued it with west systems and a clamp putting the final rings on along with the cap after I faced the sleeve which I glued on first. I don't think it broke out when I slid it together but I'm not sure why it would be solid black in there instead of clear epoxy if it had. Any tips on using veneer rings would be appreciated.

Thanks,

JC