I have a new hightower lathe on it's way, Just wondering whats the best size tool bit handle to use, I had a lathe from Todd before and It had a small 1/4 tool bit on it. I hated it being that small it felt like it was a toy.

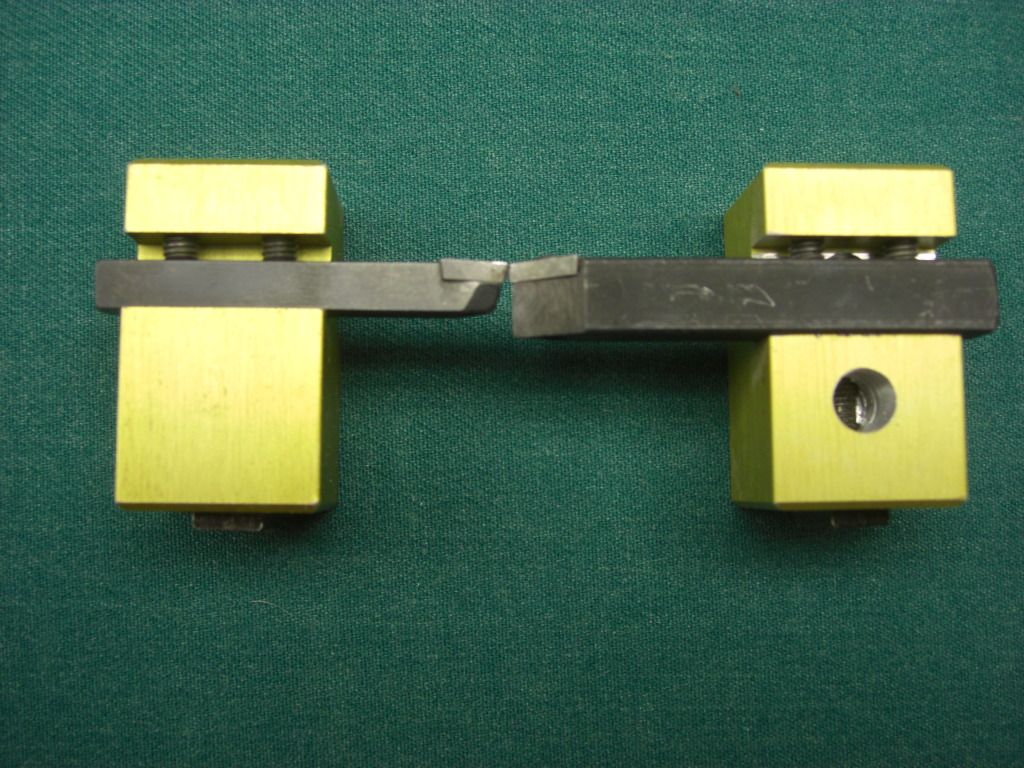

I think the Hightower lathe comes with the same size. I want to change to at least a bigger size like 3/8. I plan on buying a 5 piece set of handles and some nice carbide inserts. I know I will have to change the tool handle block, Just wondering how Big I can go, I think 3/8 would be better then the standard 1/4, Should I go bigger then 3/8, Do you think 1/2 is to big for this small taig based lathe. What do you guys use that have hightower lathes, Thanks for any help,

I think the Hightower lathe comes with the same size. I want to change to at least a bigger size like 3/8. I plan on buying a 5 piece set of handles and some nice carbide inserts. I know I will have to change the tool handle block, Just wondering how Big I can go, I think 3/8 would be better then the standard 1/4, Should I go bigger then 3/8, Do you think 1/2 is to big for this small taig based lathe. What do you guys use that have hightower lathes, Thanks for any help,