Arnot,

I am not trying to hurt your feelings but IMO you have this coming by your personall attack of my character. Your only claim to fame is that you are malcontented and always attacking people here. Go back and re-read you past threads and posts. They are all negative about someone or something. You also like to tell young people that they should quit cue making for some reason or another. What's going on in your pea brain? For that you are consistent.

Don't put words in my mouth when I correct your misstatement about other professional who use this style pin. When I stated those names it was to explain that their other top professionals use that style after you said no one did. That is called presenting evidence. You deal in subjectivity constantly and your ego is very revealing.

So when you make an asinine statement and are proved wrong beyond a shadow of a doubt, all you can do is attack me for saying something that is completely germane and true. Name dropping, I think not. I am not, nor will I ever be attacked by the likes of you and take it sitting down. You make it personal. They must have beat you during potty training.

Go back and re read my threads and posts and I think you will find that I try to share and make friends because I was trained me at a young age that you get more bees with honey than you do with vinegar and it is always better to have friends, not enemys.

I have been actively trying to change the culture of this forum in my own small ways through subtle repetition for years now and I think in my own small way it is changing. Except for the likes of your kind. Sharing info, peer check & review and positive influence helps all that play in a sand box well together.

Why because I love cue making and the people who also love it share a lot of the same things. There are many people here who I have relationships with who are also trying the change the culture hear and see you as a distraction and obstructionist. I don't care how many thousands of cues you claim to have made, it gives you no right to undermine other people.

You my friend are disillusioned and use this forum to attack and bully through your own ignorance. You are a Internet Troll personified.

Rick

Thank you for your kind remarks. They certainly speak to your character. Just for the record it appears to me that you are indeed trying to hurt my feelings. Anything someone like you says cannot hurt me because I consider the source.

Regardless of what you say .. I have read many of your post where you drop names in such a way as to imply that you have a close relationship to many other professional (long time and well respected) cuemakers.

If you do anything for someone (such as letting someone use your doweling machine) you milk that thread for all it is worth.

If it is not "self-serving" in some way.. you don't post it.

I don't know why you refer to me as "my friend" when it is obvious that we are not friends.

Really -- A high-res picture of a 3/8-14 pin!! That is not self-serving? And Troll Spray - Designed to remove unwanted trolls from message boards. You are the one trying to make someone leave this board -- Not me.

If the shoe fits, wear it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What threads are really the best???? for putting 2 pieces together as 1,and why not s

- Thread starter HollyWood

- Start date

The timing of my post may be out of sequence considering the turn this

thread is taking but none the less......I'll post it for it's content.

We all need more bastard pins like we need hemorrhoids. Just another pain in the a$$.

Don't you ever wonder why there are only 2 builders who use the 3/8x14???

The "Exclusivity" aspect may be personally appealing and provide a marketing stimulus

but in the real-world (after the sale), it sucks.

Where's the client supposed to have his/her cue serviced? 'Sorry, no gots the adapter'.

Even a simple wrap change can be a nightmare for the C-Tec and ultimately the client.

After the client has been around the block 1/2 doz times looking for someone to work on

their cue, they come to the realization that they have to send it back to you.

What started out as a 1/2 hr service now becomes a week that the client will be without their cue.

Look, builders are free to use any pin configuration that suits their fancy.

Most configurations are adequate and in most cases, specific tooling is readily available.

The sale is one thing. Service after the sale is quite a different matter.

I don't believe that exclusivity has the best interests of the client at heart.

thread is taking but none the less......I'll post it for it's content.

We all need more bastard pins like we need hemorrhoids. Just another pain in the a$$.

Don't you ever wonder why there are only 2 builders who use the 3/8x14???

The "Exclusivity" aspect may be personally appealing and provide a marketing stimulus

but in the real-world (after the sale), it sucks.

Where's the client supposed to have his/her cue serviced? 'Sorry, no gots the adapter'.

Even a simple wrap change can be a nightmare for the C-Tec and ultimately the client.

After the client has been around the block 1/2 doz times looking for someone to work on

their cue, they come to the realization that they have to send it back to you.

What started out as a 1/2 hr service now becomes a week that the client will be without their cue.

Look, builders are free to use any pin configuration that suits their fancy.

Most configurations are adequate and in most cases, specific tooling is readily available.

The sale is one thing. Service after the sale is quite a different matter.

I don't believe that exclusivity has the best interests of the client at heart.

I quit using the radial because at the time I thought it was a fad and would end up a bastard thread. Guess I was wrong. Once I burn through my 3/8-11 I may switch back. May take a while because I mainly do 5/16-14 piloted.

Aren't ball screws designed to have less play and smoother movement ?

They don't bind b/c they have balls that ride them.

In the case of cues, they have non-moving wood threads bound to them so they should stay intact, I think.

You answered your own question in your first sentence. Yes, they were designed to have less play AND smoother movement that requires less work to rotate, hence my decision that I don't want radial threads for my cues. People make good cues with them all the time. I imagine they are easier to center, but applying and holding torque is not what they were designed for. Screws with a standard machine thread are harder to center but were designed for torque. It's a compromise.

Paul,

Holding a minor and cutting a thread is not the same as making a complex 4 axis radial pin geometry. Apples and oranges. In the long run I did save about $ 5.00 per pin but money has never been a motivation for me.

In marketing, "Exclusivity" sometimes separates one from the pack. I did not plan to have a pin that was different than a standard, it just happened that way. Today I am glad it is non standard. Custom Made Cues should have custom feature elements to separate them from other cues. Choices are good for buyers.

Mike Bender and Ed Young aren't losing sales with a non standard pin and I don't think it will hurt my sales. It hasn't so far. People like things that are different.

I have had strangers that never touched one of my cues order a cue from me because they heard I have this pin. Go figure. If they think it makes the cue play better that's OK as long as I tell them it's the shaft contour and balance that does. As I said, I don't think the 14 tpi modified plays better than a 10 or 11 modified.

I also have done a lot of Omega DPK restorations and made over 40 shafts for Omega and Bender Cues for customers. Having this non standard tooling has made me many thousands of dollars. I am sure that someone like Ryan or KJ has this kind of tooling but I bet there is not too many others.

Rick G

Hi Rick

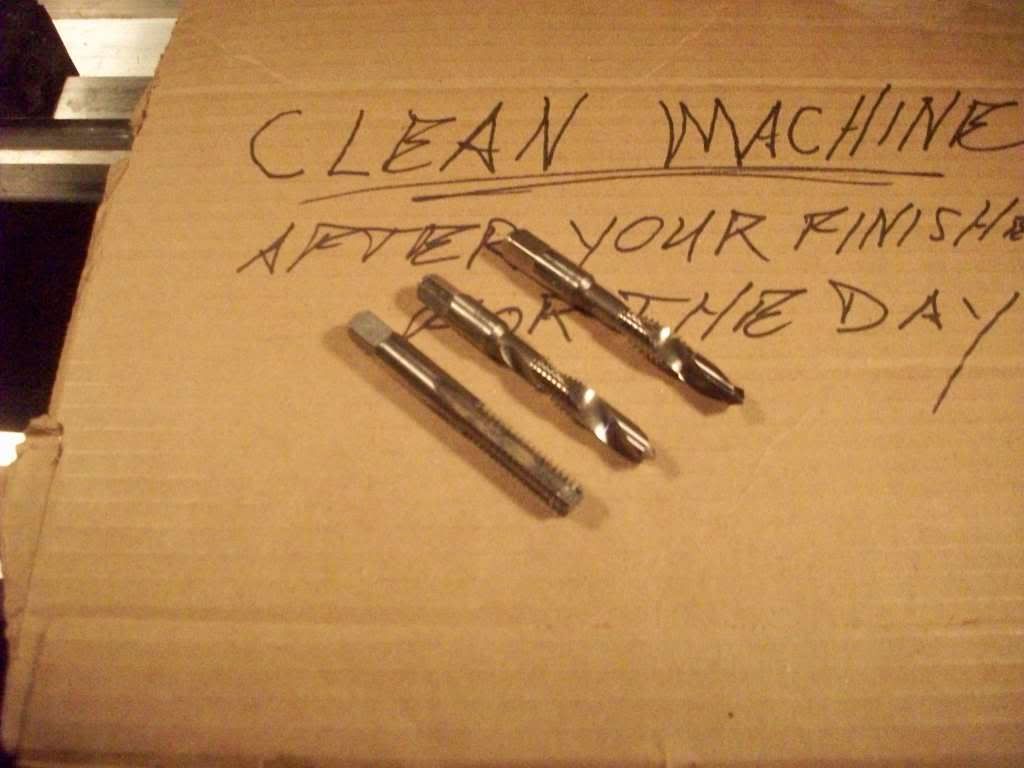

I have 3 taps for this pin, all a little different. But anyways, I take the pin you choose to use in your cues as your right to use it based on your personal, professional opinion. I can respect that. I have nothing against different sized screws, It just means, if you want to work on it, Go shopping or leave it alone. Might be a safe bet, I have more taps and dies than most of this board. I like it.

Last edited:

Mike,

I use three taps also. One ground down on the drill fluke. One standard ( no grinding ) and a bottom tap. Taps are cheap.

The only cues I can't do work on is the Schlmeke thing. But thats a horse of a different color.

Like my coach used to say, "be good at all sports".

I love CNC Drill Taps.

Thanks,

Rick

I use three taps also. One ground down on the drill fluke. One standard ( no grinding ) and a bottom tap. Taps are cheap.

The only cues I can't do work on is the Schlmeke thing. But thats a horse of a different color.

Like my coach used to say, "be good at all sports".

I love CNC Drill Taps.

Thanks,

Rick

Last edited:

Mike,

I use three taps also. One ground down on the drill fluke. One standard ( no grinding ) and a bottom tap. Taps are cheap.

Like my coach used to say, "be good at all sports".

I love CNC Drill Taps.

Thanks,

Rick

I wish they were cheap, Widell and North American zap you with the set up charge, 100 to 150 per tap and 100 for the split dies. But back in the day when only a few of us worked tournaments. They were an important part of shaft sales. The discussion between Cue makers and repair people were very limited,

Last edited:

If you do anything for someone (such as letting someone use your doweling machine) you milk that thread for all it is worth.

If it is not "self-serving" in some way.. you don't post it.

Arnot,

You think you can read people's minds and can make statements about my intentions. You are wrong in so many ways.

Here is the thread that I posted to try to promote Geoff's new business venture which you referenced to. Milking a thread???? Read it then re-read your quote about me being "self serving" above that are your paranoid mind reading words. You don't make any sense and your arguments are again circular, don't hold water and defies logic.

http://forums.azbilliards.com/showthread.php?t=246414

Please show me where I made one statement other than to promote some other guy's business who I believe has fantastic shaft stock. Trying to help someone you respect is not self serving. If I am wrong please explain.

Please note that I have no skin in his game at all.

In an Objectivist's Philosophy, "Self Promotion" is human nature and is a survival virtue of man unless you are collectivist you should embrace this notion and not be offended if someone else practices it. We all self promote and I am no different from the next guy. BTW, I am an Objectivist and proud to be one.

On the internet we are in the public's view and it only makes sense to define yourself in a positive way.

You are never positive! Even when you give sound advice to someone you always find a way to act like an expert jerk.

BTW, stop calling my phone as you are persona non grada in my book.

The last time you called me to tell me I was a liar and that my shafts are no good ( without ever actually ever inspecting one ), I told you to stop call me and hung up. While you were calling me a liar you were suggesting that you called to help me out. I don't need your help.

Quit being a stalker and let it go! What I do is none of your business.

What do you do, get up in the mornings and say, what can I do to piss someone off today. You are a pro , start acting like one.

BTW self defense is also a survival virtue. If you keep pissing on my fire hydrant I will keep defending my self with logical arguments and evidence until you shut up. Want to continue this pissing match, give it you best shot!!!!! I will not back off from the likes of you. Right has might!

Now go ahead and run to Mr. Wilson to report my behavior. That's your style, is it not?

Rick Geschrey

Last edited:

Arnot,

You think you can read people's minds and can make statements about my intentions. You are wrong in so many ways.

Here is the thread that I posted to try to promote Geoff's new business venture which you referenced to. Milking a thread???? Read it then re-read your quote about me being "self serving" above that are your paranoid mind reading words. You don't make any sense and your arguments are again circular, don't hold water and defies logic.

http://forums.azbilliards.com/showthread.php?t=246414

Please show me where I made one statement other than to promote some other guy's business who I believe has fantastic shaft stock. Trying to help someone you respect is not self serving. If I am wrong please explain.

Please note that I have no skin in his game at all.

In an Objectivist's Philosophy, "Self Promotion" is human nature and is a survival virtue of man unless you are collectivist you should embrace this notion and not be offended if someone else practices it. We all self promote and I am no different from the next guy. BTW, I am an Objectivist and proud to be one.

On the internet we are in the public's view and it only makes sense to define yourself in a positive way.

You are never positive! Even when you give sound advice to someone you always find a way to act like an expert jerk.

BTW, stop calling my phone as you are persona non grada in my book.

The last time you called me to tell me I was a liar and that my shafts are no good ( without ever actually ever inspecting one ), I told you to stop call me and hung up. While you were calling me a liar you were suggesting that you called to help me out. I don't need your help.

Quit being a stalker and let it go! What I do is none of your business.

What do you do, get up in the mornings and say, what can I do to piss someone off today. You are a pro , start acting like one.

BTW self defense is also a survival virtue. If you keep pissing on my fire hydrant I will keep defending my self with logical arguments and evidence until you shut up. Want to continue this pissing match, give it you best shot!!!!! I will not back off from the likes of you. Right has might!

Now go ahead and run to Mr. Wilson to report my behavior. That's your style, is it not?

Rick Geschrey

Mr. Geschrey I think you are losing it.

I have only spoken to you on the phone on one occasion and that was to try to help you and you never took the time to listen to what I had to say.

What you call defining yourself in a positive manner is what we call "blowing your own horn". However, in this email I think you might have missed the mark.

It sounds to me like you are the one who wakes up in the morning thinking that wierd stuff about ***** somebody off. I would not want to read your mind.

The more you write the more everybody finds out who and what you are.

Good luck in your life and your work with cues.

Mr. Geschrey I think you are losing it.

I have only spoken to you on the phone on one occasion and that was to try to help you and you never took the time to listen to what I had to say.

What you call defining yourself in a positive manner is what we call "blowing your own horn". However, in this email I think you might have missed the mark.

It sounds to me like you are the one who wakes up in the morning thinking that wierd stuff about ***** somebody off. I would not want to read your mind.

The more you write the more everybody finds out who and what you are.

Good luck in your life and your work with cues.

Not if one knows how to read and notices that I don't make statements I can't back up like you and then refuse to acknowledge true facts as a general principal. You say things about me then when confronted with the facts, you change the subject and ignore the basis. Thats call running away and I would say you are a coward personified. BTW people tend to stop listening when you start telling them they are making untrue statements at the beginning of the call. Unbelievable gall.

The difference between you and I is that if I am wrong, I will say, "I am sorry" and move on. You just keep going lower and lower in to the crap by denying.

You can try to act cool and glib to try and bullshit other people who are observing this circus but guess what, that's a pathological behavior with an underpinning via denial. I really don't care about the circus, this is about me and you.

You are the king of obfuscation. You think I am self serving. I bet you did not reread the post. No Comments?

Here it is again:

Here is your words about a thread I started.

If you do anything for someone (such as letting someone use your doweling machine) you milk that thread for all it is worth.

If it is not "self-serving" in some way.. you don't post it.

Here is the Thread: ( I know you won't look at it because it makes you look like a horse's ass).

http://forums.azbilliards.com/showthread.php?t=246414

Now tell me again it is self serving. I have no skin in the game, I was helping someone with an observational statement.

How about this zinger: AW 101: Say stupid things, draw false conclusions, mind read other people, then put words in their mouth in public.

I am sure that any professional cuemaker has the tooling necessary to do the job correctly. But I don't know of a single professional who uses a 3/8-14 pin. To be the only one who uses a bastard thread like the 3/8-14 says in essence states that all other cuemakers in the world are wrong and he is correct in the 3/8-14 choice. NOT!!!I like the part where you say I think all other cuemakers in the world are wrong even after I said I love the Unilock radial, 3/8 10 & 11. In fact I like all pins and never would hurt someone's feeling even if I did not like their pin. That's just common courtesy, something you are not familiar with.

Every statement you said here puts false words in my mouth, is categorically wrong and has no basis other than your mind projections. Then when I mention 3 Cue Makers that use it you call me a name dropper. I have every right to defend myself and will do it until the day I die if you wish to continue bumping. You have no idea who I am or my resolve concerning character attacks.

Do you know how stupid that makes you look. I personally don't care if you want to be stupid but when you attack me while being stupid, I'll roll in the dirt with you because I am right. Not just a little right, 100% right.

What really pissed me off is when you tried to break the spirit of a new cue maker who made his own wrap press. Telling him he should get out of cue making if he could not afford to buy one. Many other decent people gave him Kudos about his device. You went on to tell him how many thousands of wraps you have put on with yours. Ego check!! I on the other hand told him that I liked the feature of a wider roller foot print and left any negative thoughts I had to myself knowing that all designs have a evolution curve. I accentuated the positive while you tried to break his spirit with your negativity. That must have made you feel real powerful.

You know it is a mortal sin to make false testimony against thy neighbor.

Now go ahead and tell me I am the one who's full of crap. Or maybe it could be you.

Rick Geschrey

Last edited:

First of all you need anger management counseling because you are out of control -- just like you were when I spoke with you on the phone.

Secondly, this is about your choice of joint pins; the 3/8-14. I will quote KJ's post in part:

We all need more bastard pins like we need hemorrhoids. Just another pain in the a$$.

Don't you ever wonder why there are only 2 builders who use the 3/8x14???

The "Exclusivity" aspect may be personally appealing and provide a marketing stimulus

but in the real-world (after the sale), it sucks.

Where's the client supposed to have his/her cue serviced? 'Sorry, no gots the adapter'.

Even a simple wrap change can be a nightmare for the C-Tec and ultimately the client.

After the client has been around the block 1/2 doz times looking for someone to work on

their cue, they come to the realization that they have to send it back to you.

What started out as a 1/2 hr service now becomes a week that the client will be without their cue.

Look, builders are free to use any pin configuration that suits their fancy.

Most configurations are adequate and in most cases, specific tooling is readily available.

The sale is one thing. Service after the sale is quite a different matter.

I don't believe that exclusivity has the best interests of the client at heart.

If you really cared about your customer, you would use a pin which would benefit them rather than add to your hype about exclusivity. Out of all the cuemakers in the world only you and one other have chosen to use the 3/8-14 pin which in my opinion does not make you right and the rest of the cuemakers wrong -- it means that you might reevaluate your reasons for using that pin.

In this thread you have shown your maturity with your picture of "Troll Spray", Hi-Res pictures of a joint pin and taps, words like asinine, jerk, pissing, pissing someone off, stalker, pissing on my fire hydrant, calling me a coward personified, cool and glib, and bullshit.

Instead of attacking me with profanity why don't you stay on point and tell us what is so good about your pin choice other than it makes you exclusive. I cannot think of a single reason for your choice of pins when compared to the Radial Pin (tm), 3/8-10 and 3/8-11, 5/16-14 and 5/16-18 of which all of these pins are available "off the shelf" with drivers and and sanding mandrels. Having items available off the shelf is good for the customer because any cuemaker or repair person can work on their cues. They are not locked in to you when they need a new shaft or other repair as KJ pointed out.

Cuemaking is not all about what is good for the cuemaker; the customer is more important in my opinion.

Have a nice day Sir,

Secondly, this is about your choice of joint pins; the 3/8-14. I will quote KJ's post in part:

We all need more bastard pins like we need hemorrhoids. Just another pain in the a$$.

Don't you ever wonder why there are only 2 builders who use the 3/8x14???

The "Exclusivity" aspect may be personally appealing and provide a marketing stimulus

but in the real-world (after the sale), it sucks.

Where's the client supposed to have his/her cue serviced? 'Sorry, no gots the adapter'.

Even a simple wrap change can be a nightmare for the C-Tec and ultimately the client.

After the client has been around the block 1/2 doz times looking for someone to work on

their cue, they come to the realization that they have to send it back to you.

What started out as a 1/2 hr service now becomes a week that the client will be without their cue.

Look, builders are free to use any pin configuration that suits their fancy.

Most configurations are adequate and in most cases, specific tooling is readily available.

The sale is one thing. Service after the sale is quite a different matter.

I don't believe that exclusivity has the best interests of the client at heart.

If you really cared about your customer, you would use a pin which would benefit them rather than add to your hype about exclusivity. Out of all the cuemakers in the world only you and one other have chosen to use the 3/8-14 pin which in my opinion does not make you right and the rest of the cuemakers wrong -- it means that you might reevaluate your reasons for using that pin.

In this thread you have shown your maturity with your picture of "Troll Spray", Hi-Res pictures of a joint pin and taps, words like asinine, jerk, pissing, pissing someone off, stalker, pissing on my fire hydrant, calling me a coward personified, cool and glib, and bullshit.

Instead of attacking me with profanity why don't you stay on point and tell us what is so good about your pin choice other than it makes you exclusive. I cannot think of a single reason for your choice of pins when compared to the Radial Pin (tm), 3/8-10 and 3/8-11, 5/16-14 and 5/16-18 of which all of these pins are available "off the shelf" with drivers and and sanding mandrels. Having items available off the shelf is good for the customer because any cuemaker or repair person can work on their cues. They are not locked in to you when they need a new shaft or other repair as KJ pointed out.

Cuemaking is not all about what is good for the cuemaker; the customer is more important in my opinion.

Have a nice day Sir,

You answered your own question in your first sentence. Yes, they were designed to have less play AND smoother movement that requires less work to rotate, hence my decision that I don't want radial threads for my cues. People make good cues with them all the time. I imagine they are easier to center, but applying and holding torque is not what they were designed for. Screws with a standard machine thread are harder to center but were designed for torque. It's a compromise.

I haven't found any difference in centering any screw but I do know that a Uni-Loc Radial with an undersized tap makes the tightest fit of any screw out there and with the very high quality finish on the pin, it stays snug for many years. You get what you pay for.

I'm can't figure out what the problem is with a screw that has less play, rotates more smoothly, and stays tightly closed. You don't have to torque the hell out of them to get them perfectly closed. As a separate observation, you can play pool with a cue that has a half inch gap between the shaft and butt with a Radial, they fit that well.

First of all you need anger management counseling because you are out of control -- just like you were when I spoke with you on the phone.

Secondly, this is about your choice of joint pins; the 3/8-14. I will quote KJ's post in part:

We all need more bastard pins like we need hemorrhoids. Just another pain in the a$$.

Don't you ever wonder why there are only 2 builders who use the 3/8x14???

The "Exclusivity" aspect may be personally appealing and provide a marketing stimulus

but in the real-world (after the sale), it sucks.

Where's the client supposed to have his/her cue serviced? 'Sorry, no gots the adapter'.

Even a simple wrap change can be a nightmare for the C-Tec and ultimately the client.

After the client has been around the block 1/2 doz times looking for someone to work on

their cue, they come to the realization that they have to send it back to you.

What started out as a 1/2 hr service now becomes a week that the client will be without their cue.

Look, builders are free to use any pin configuration that suits their fancy.

Most configurations are adequate and in most cases, specific tooling is readily available.

The sale is one thing. Service after the sale is quite a different matter.

I don't believe that exclusivity has the best interests of the client at heart.

If you really cared about your customer, you would use a pin which would benefit them rather than add to your hype about exclusivity. Out of all the cuemakers in the world only you and one other have chosen to use the 3/8-14 pin which in my opinion does not make you right and the rest of the cuemakers wrong -- it means that you might reevaluate your reasons for using that pin.

In this thread you have shown your maturity with your picture of "Troll Spray", Hi-Res pictures of a joint pin and taps, words like asinine, jerk, pissing, pissing someone off, stalker, pissing on my fire hydrant, calling me a coward personified, cool and glib, and bullshit.

Instead of attacking me with profanity why don't you stay on point and tell us what is so good about your pin choice other than it makes you exclusive. I cannot think of a single reason for your choice of pins when compared to the Radial Pin (tm), 3/8-10 and 3/8-11, 5/16-14 and 5/16-18 of which all of these pins are available "off the shelf" with drivers and and sanding mandrels. Having items available off the shelf is good for the customer because any cuemaker or repair person can work on their cues. They are not locked in to you when they need a new shaft or other repair as KJ pointed out.

Cuemaking is not all about what is good for the cuemaker; the customer is more important in my opinion.

Have a nice day Sir,

Now I don't care about my customers. Change the subject and run off at the mouth again with blind and asinine assumptions. They have a choice to buy whatever cue they want and know what pin is on my cue when they make a transaction. As for profanity, there is a time and place for it, and I think this is the time and place for such narratives and descriptions when dealing with such a jerk like you. You deserve to know how I feel about you and I don't like Marcus of Queensberry rules when I fight.

A+B=C Not A+B equals whatever rolls off your tongue at the time to try to mud the waters. Did you ever attend a school in your life? Your logic and thinking is flawed big time and you are hurtful to others. Any comments about the "you should get out of the business" to the guy who made the wrap press. Silence I bet!!!! Feeling proud of yourself! I don't think you can find a quote to hide behind on that one. Or was that just a slip of the tongue or a tongue and cheek humor statement.

You are still in denial and want to change the subject about why you choose to attack my character. That is why I continue to defend myself from your lies and BS. All this other stuff you bring up is just changing the subject. Again, over and over. Now you are hiding behind something someone else said as some kind of chicanery. I guess you didn't re read your bullshit thread and my posts that you mis-quoted me on and started mind reading, because therein lies the truth.

Any comments KJ said was his opinion and said in a respectful manner as is always his way. It's OK to disagree it's not OK to call people names and demean them.

Since you drew first blood attacking my character and I never call people names or attack, I get a free pass on this one because you are such a A** Hole.

Go ahead and keep bumping this thread. It is now up to 900 viewers. Let see if we can get it up to 10,000.

My question to you is how many pool cue students do you think will sign up if you keep acting like such a jerk to people on AZ. If you want to start fires, remember gas is the accelerator. Just think of me as the gas can stupid.

I am a published author and love to write. If you want to do "War and Peace", keep on bumping with your false statements and innuendoes. I'll keep throwing my tomatoes at a bad vaudeville act.

I am having a nice day BTW,

Rick Geschrey

PS:

I was asked by Macguy why I did not use a standard pin:

Here is my reply to him that somehow made you go after me. Please notice that I did not say any thing about my pin being better and I also said I wish to use the Unilock radial but was kinda forced into this pin:

Just curious, why would you have these pins made? Why not just use a 5/16 x 14 or 18 to make a flat faced joint? Or any of the larger pins for that matter that are already out there?

Mac,

I see your point and it is a very logical question. The reason I went with this pin is a long story. Sometimes in life you go down a road that you don't choose and in the end it turns out to be a better road trip.

When I first started in my cue making journey I had been doing a lot of cue repair at my pool hall and when I made my first cues I used the Unilock Radial Pin and liked it's engineering attributes. I am a huge fan of anything to do with Bill Stroud's philosophy in cue making. Bill, David and Burton are my favorite Cue Makers.

When I started to make the financial commitment to purchasing plant equipment and tooling to build a Cue Shop I teamed up with my mentor Ray Hernandez. Ray was the last cue maker to work in Waconda, Il. at the Omega DPK shop. When Ray and I started our partnership he told me flat out that he was not coming onboard unless we used the 3/8 x 14 pin and he did not want to use anything else.

Many years ago my friend and neighbor (the late) John Wright was involved in the start up of Omega and I remember him telling me about this pin as it was a thread design change from David's modified.

I listened to Ray and I am glad I did. Ray is a retired tool and die engineer and he had the tooling made for the screw machine production and changed the nose contour geometry so our pin was not an exact copy of Omega's pin. Only the thread features matches Omega or Mike Bender's Pin.

Downside is I had to make my own maintenance pins as they are not available commercially. No big deal. Upside is "exclusivity" as this pin is only used by a few cue makers as far as I know. These pins are triple chrome plated brass and when these run out I have plans to go to Monel without plating.

I don't think it performs better than a 3/8 X 10 or 11 modified, it's just a 14.

Rick G

After having 500 units produced I am pretty much committed to this pin. All of my cues have it and only a few of my first cues had the Radial Pin like JW.

Last edited:

I haven't found any difference in centering any screw but I do know that a Uni-Loc Radial with an undersized tap makes the tightest fit of any screw out there and with the very high quality finish on the pin, it stays snug for many years. You get what you pay for.

I'm can't figure out what the problem is with a screw that has less play, rotates more smoothly, and stays tightly closed. You don't have to torque the hell out of them to get them perfectly closed. As a separate observation, you can play pool with a cue that has a half inch gap between the shaft and butt with a Radial, they fit that well.

That settles that .

Mr. Geschrey do you only like me when I agree with you?

I will admit that I was surprised when I found this post you made on 7-4-2010:

"Hi,

Arnot's cues look and play great but what's more relevant is that he is a great guy and very helpful to other cue makers who wish to listen. Truly a "class act" as a person!

Rick Geschrey "

I will admit that I was surprised when I found this post you made on 7-4-2010:

"Hi,

Arnot's cues look and play great but what's more relevant is that he is a great guy and very helpful to other cue makers who wish to listen. Truly a "class act" as a person!

Rick Geschrey "

Mr. Geschrey do you only like me when I agree with you?

I will admit that I was surprised when I found this post you made on 7-4-2010:

"Hi,

Arnot's cues look and play great but what's more relevant is that he is a great guy and very helpful to other cue makers who wish to listen. Truly a "class act" as a person!

Rick Geschrey "

That was before you spewed poison in my direction for the 2nd time for no good reason. Now that you bring this up, I will be truthful by saying I was trying to use some child or reverse psychology to curb your aggressive negativity but I guess it didn't work. As I said before, myself and others here would like to see people use these threads in a more positive direction. You just don't fall under that kind of culture as an individual I guess.

I must have had some kind of self promotion in mind when I said these nice things about you and your product. Yea Right!

I see many of your cues come thru my pool room and have inspected them and they are very nice but if they were sucko, I would not comment at all. This was never about your talent as a CM.

Again, you are a pro, start acting as such and stop the personal attacks and negativity. I think we all would be better off.

I will never standby and let you attack me in public with lies, name calling, and mind reading untruths. You have tried to change the subject of my "calling you out" in every post you have made thereafter. I have stayed on the topic without a single response that makes any sense from you. Obfuscation? Thats standard operational procedure for pathological liars. If it acts like a duck, walks like a duck and quacks like a duck, well I think we all know what it is.

Rick

Last edited: