Get the correct inserts unless you want the grind down multiple holders....

Randy, this thread is 3 months short of celebrating A YEAR. That is how long I was trying to get the inserts. I would have been thankful for a post like "you need this, go here and buy this, check here how it looks like, etc." But instead I had to do lots of guessing, searching, inquiring, etc. There even were a couple of PMs asking me to share the source had I succeeded in my search. Finally I did, so it's about time to give them an answer.

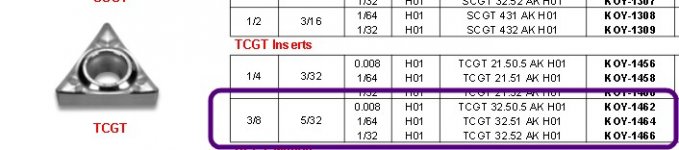

First I was caught by a post JoeyinCali made about how good tcgt-s are. There is a link to it in my opening post of this very thread, but to save time and clicks I will copy one of the images here.

So these were the ones I was looking for. I had nothing but this code to start with.

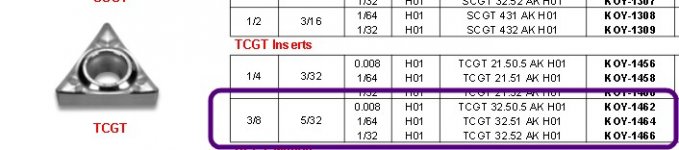

Here is what I finally succeeded to buy

The letters do match, don't they? Hurrah.

I wish I got Dave's attention in the beginning of my quest, I would have at least known "3/8" can be different. Lucky me, he clarified that only after I got new inserts. And noone else ever did mention that.

So I will have to do by trial and error, sometimes like a blind man. And people around could stay and be amazed at how he can't find his way. I just have to be going further.

The TCGT 32.52-AK HO1 fits my 3/8 tool holders

and apparently doesn't fit mine. I got my current toolholder from Unique Prod. and I know it is 3/8 from their catalog:

Like I said, I thought 3/8 holder and 3/8 insert go along well. Hmm...

You see how complicated this is.