As you all know, I have been working on a new carriage for taig base dovetail. This carriage has by far met an exceeded my expectations, for smoothness redgidity and the effortless moving motion it requires. this carriage will not only provide much higher snugg fit to the dovetail than the standard carriages it will also give you a scratchless carriage. no more scratched dove tail either, with a 100% UHMW interface between carriage and dovetail, it makes it impossible to scratch the dovetail.

this carriage will be standard on all my new high end Cue Lathes ( Cue Building Lathe, Fully Loaded Repair Lathes, plus all Custom Lathes Built on my H-channel)

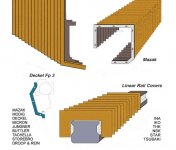

Here are some pictures of the new carriage along with a closeup picture on the new Gear Rack and pinion Gear.

YouTube Link

http://www.youtube.com/watch?v=QHS9AEp7iC8&feature=youtu.be

Regards

Bassel

Custom Cue Lathes

customcuelathes@yahoo.com. gmail.com, & hotmail.com

248-884-4469

this carriage will be standard on all my new high end Cue Lathes ( Cue Building Lathe, Fully Loaded Repair Lathes, plus all Custom Lathes Built on my H-channel)

Here are some pictures of the new carriage along with a closeup picture on the new Gear Rack and pinion Gear.

YouTube Link

http://www.youtube.com/watch?v=QHS9AEp7iC8&feature=youtu.be

Regards

Bassel

Custom Cue Lathes

customcuelathes@yahoo.com. gmail.com, & hotmail.com

248-884-4469

Attachments

Last edited: