Compression = Janka???? that's what I was wondering. How does it resist/withstand compression? We all know the stuff has flexibility. But if you hammer on it parellel to the grain what's it do? I assume thats how its orientated.No, flex is a different property when discussing wood. Janka hardness is a measure of force required for a steel ball to indent a piece of wood to a certain depth.

Modulus of elasticity is the measure of (non permanent) flexing.

Kelly

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

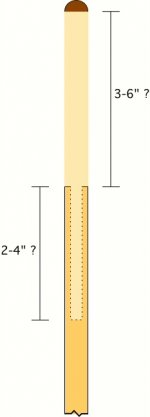

bamboo ferrule

- Thread starter desi2960

- Start date

Compression = Janka???? that's what I was wondering. How does it resist/withstand compression? We all know the stuff has flexibility. But if you hammer on it parellel to the grain what's it do? I assume thats how its orientated.

Janka hardness is resistance to denting.

Compression strength is how much load it can take parallel to the grain.

Bending strength is how much load it can take perpendicular to the grain.

Modulus of elasticity...already mentioned.

http://workshopcompanion.com/KnowHow/Design/Nature_of_Wood/3_Wood_Strength/3_Wood_Strength.htm

Once you get into laminates and such, raw numbers found on the internet may not really apply. I suspect the janka rating for laminated bamboo would be the same, but certainly the other properties would change. Kind of hard to say, each specific engineered piece would have to be tested I would think.

Kelly

Taking it further

So if bamboo is about the same hardness as maple, the hit should have a similar feel; good thing.

Bamboo is half the weight of maple and therefore even lighter still than other traditional ferrule materials, so the deflection would be reduced; good thing.

And bamboo is really strong, good thing.

The low deflection school of thought says to reduce the weight in the front few inches of the shaft, hence Predator's drilled out hole. I believe it's 5 inches, but not sure.

How about taking this all one step further and replacing the entire front 5 or so inches with bamboo using a tenon pointing in the opposite direction. Sound feasible? I have no idea how long to make the tenon, the rest is for the engineers and cue makers. I'm just the idea guy.

Fatz

So if bamboo is about the same hardness as maple, the hit should have a similar feel; good thing.

Bamboo is half the weight of maple and therefore even lighter still than other traditional ferrule materials, so the deflection would be reduced; good thing.

And bamboo is really strong, good thing.

The low deflection school of thought says to reduce the weight in the front few inches of the shaft, hence Predator's drilled out hole. I believe it's 5 inches, but not sure.

How about taking this all one step further and replacing the entire front 5 or so inches with bamboo using a tenon pointing in the opposite direction. Sound feasible? I have no idea how long to make the tenon, the rest is for the engineers and cue makers. I'm just the idea guy.

Fatz

Attachments

Keep in mind Tom that Gooder to Good is akin to Fun and Funner.

Gooder never trumps Bestest.

Gooder Fun is the same as Funner.

Gooder never trumps Bestest.

Gooder Fun is the same as Funner.

Bamboo

I tried making shafts from laminated Tonkin bamboo (same as in fly rods) but

once I had cut it below 15mm it was, for all practical purposes, just like a

fly rod. The modulus of elasticity is poor, however the compression strength

is excellent and it is very light. Here is a comment from my website regarding

bamboo: "A few words about bamboo: I have long been interested in bamboo as a material to use in cues since my frequent trips to Asia showed me the strength of bamboo used for scaffolding in buildings that were 30 stories and more high.

My interest peaked when my grand sons told me they were now using bamboo to make baseball bats. Evidently the ball just flies off the bat, much like it does with aluminum bats. Further research revealed that bamboo has a tensile strength of 28,000 pound per square inch as compared to steel at 23,000 psi. Those figures are for raw bamboo, not laminated which

increases the tensile strength many fold. The best bamboo to use for baseball bats (and pool cues) is called "Tonkin" which comes from Guangdong Providence in China. This is the same species that is used to make flyrods. I was fortunate enough to find a company that made laminates from Tonkin in a 3/4" thickness. By glueing two laminates together I had a 1 1/2" turning square. Further research into bamboo baseball bats revealed that the top-of-the-line baseball bats were cored. That fit my cue making philosophy perfectly because I full length core all my cues, usually with purple heart. The result is a unique cue that has the attributes of a cored bamboo baseball bat. These are strength with just the right amount of flex, the lovely feel and look of bamboo and the "hit" which can be described as "lively". Try one of my hybrid bamboo cues--you will not be disappointed.

I tried making shafts from laminated Tonkin bamboo (same as in fly rods) but

once I had cut it below 15mm it was, for all practical purposes, just like a

fly rod. The modulus of elasticity is poor, however the compression strength

is excellent and it is very light. Here is a comment from my website regarding

bamboo: "A few words about bamboo: I have long been interested in bamboo as a material to use in cues since my frequent trips to Asia showed me the strength of bamboo used for scaffolding in buildings that were 30 stories and more high.

My interest peaked when my grand sons told me they were now using bamboo to make baseball bats. Evidently the ball just flies off the bat, much like it does with aluminum bats. Further research revealed that bamboo has a tensile strength of 28,000 pound per square inch as compared to steel at 23,000 psi. Those figures are for raw bamboo, not laminated which

increases the tensile strength many fold. The best bamboo to use for baseball bats (and pool cues) is called "Tonkin" which comes from Guangdong Providence in China. This is the same species that is used to make flyrods. I was fortunate enough to find a company that made laminates from Tonkin in a 3/4" thickness. By glueing two laminates together I had a 1 1/2" turning square. Further research into bamboo baseball bats revealed that the top-of-the-line baseball bats were cored. That fit my cue making philosophy perfectly because I full length core all my cues, usually with purple heart. The result is a unique cue that has the attributes of a cored bamboo baseball bat. These are strength with just the right amount of flex, the lovely feel and look of bamboo and the "hit" which can be described as "lively". Try one of my hybrid bamboo cues--you will not be disappointed.

So if bamboo is about the same hardness as maple, the hit should have a similar feel; good thing.

Bamboo is half the weight of maple and therefore even lighter still than other traditional ferrule materials, so the deflection would be reduced; good thing.

And bamboo is really strong, good thing.

The low deflection school of thought says to reduce the weight in the front few inches of the shaft, hence Predator's drilled out hole. I believe it's 5 inches, but not sure.

How about taking this all one step further and replacing the entire front 5 or so inches with bamboo using a tenon pointing in the opposite direction. Sound feasible? I have no idea how long to make the tenon, the rest is for the engineers and cue makers. I'm just the idea guy.

Fatz

Hi,

I used to have a bamboo bong that lasted for years. We also put ice water in it and it did not seem to bother it.

Maybe it would be ok for a ferrule. Do Some years of field beta testing before making a final judgment.

I think I would want a banana peel wrap on the handle. Just a joke!

Seriously there are no bad ideas. Bamboo may have some merit if it does not crack in this application.

Good luck and keep us up dated with further info.

Rick G

I used to have a bamboo bong that lasted for years. We also put ice water in it and it did not seem to bother it.

Maybe it would be ok for a ferrule. Do Some years of field beta testing before making a final judgment.

I think I would want a banana peel wrap on the handle. Just a joke!

Seriously there are no bad ideas. Bamboo may have some merit if it does not crack in this application.

Good luck and keep us up dated with further info.

Rick G

Bamboo

Probably too light and not stiff enough (modulus of elasticity as mentioned by Kelly).

Probably too light and not stiff enough (modulus of elasticity as mentioned by Kelly).

Hmmm...makes one wonder how it might be as a cue core.......

.

Probably too light and not stiff enough (modulus of elasticity as mentioned by Kelly).

Interesting.

Relieve me of my ignorance then. What would be the significant difference structurally, weight wise, flex wise, etc between using it on the outside of a hard wood cored cue versus using it as a core in a cue with the hard wood on the outside?

After all, you are using it on the outside sleeved over a core of hard wood, right?

I am assuming it would be radially laminated in such an application, which would, I think, make it substantially stiffer. Then of course it would be surrounded by hard wood.

Forgive my amateurish questions, I am the curious type.

Chop, I like the idea of a bamboo core--it may allow a very structurally sound cue which is easier to be produced in very light weight without sacrificing final diameter.

dld

Not only that but wouldn't generally lighter material also mean that one would be more free to determine where the weight is concentrated?

You may want to ask one of the pool cue history buffs, but I believe bamboo was once used as a ferrule many years ago.

As for using it for a core, it shouldn't affect the stiffness much, but it would alter the hit. I'm not really sure how since lighter cues tend to give a sharper recoil but I'm not sure how to approach the different densities. Softer materials tend to dampen the felt impact, but hardness is often relative to the density. That goes out the window with bamboo.

In sheetmetal structures, a comparatively soft material (some sort of plastic or even balsa wood) can be placed between two thin sheets of aluminum to make a lamination that is almost as stiff as a single thick sheet of aluminum while saving weight. In college we had to build up a lamination using fiberglass, kevlar, and some paper honeycomb. When it was cured, you couldn't bend it over your knee, but it weighed next to nothing.

Bamboo should be much more gooderer than balsa.

As for using it for a core, it shouldn't affect the stiffness much, but it would alter the hit. I'm not really sure how since lighter cues tend to give a sharper recoil but I'm not sure how to approach the different densities. Softer materials tend to dampen the felt impact, but hardness is often relative to the density. That goes out the window with bamboo.

In sheetmetal structures, a comparatively soft material (some sort of plastic or even balsa wood) can be placed between two thin sheets of aluminum to make a lamination that is almost as stiff as a single thick sheet of aluminum while saving weight. In college we had to build up a lamination using fiberglass, kevlar, and some paper honeycomb. When it was cured, you couldn't bend it over your knee, but it weighed next to nothing.

Bamboo should be much more gooderer than balsa.

Last edited:

The amount and quality of technical knowledge you guys have is amazing.

Thank you all for entertaining my thoughts on these matters. I do my best to understand and think that at least qualitatively, at a superficial level, I understand.

I will watch with interest to see what comes of any of this.

Thank you all for entertaining my thoughts on these matters. I do my best to understand and think that at least qualitatively, at a superficial level, I understand.

I will watch with interest to see what comes of any of this.

How did it work out?

Since the original post is over a year old, I'm wondering about your bamboo ferrule experiment.

Did it work ok and what are your final thoughts on it?

Where did you find the material you made it from?

Since the original post is over a year old, I'm wondering about your bamboo ferrule experiment.

Did it work ok and what are your final thoughts on it?

Where did you find the material you made it from?

in am attempt to find the perfect cue, i will try anything at least once. this is my latest brainstorm, i love the no ferrule, but a few customers are afraid and still want a ferrule. bamboo is a very strong light material [ this ferrule weighed 1/2 of a grice ferrule of the same size ]. i played last night for about 3 hrs and i think the hit is about the same as " no ferrule " i like the hit and the look.

now we just have to play for a year or so to see how it is going to stand up over time.

Wow that shaft is dark. So dark ...

I thought the same. Looks like great shaft wood to me.