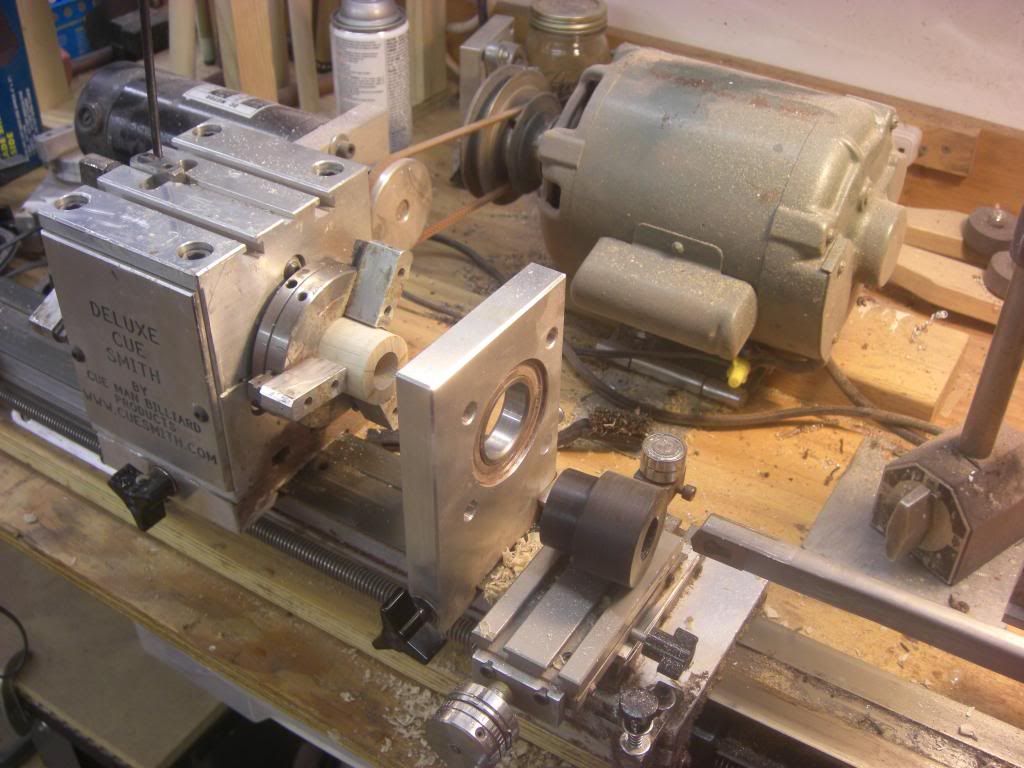

When do we start producing internally fluted low deflection shafts ?

I'm in for $1K and half of the business. :thumbup:

The cats out. True low deflection comes from rifling the hole! Helps guns shoot straighter, why haven't cues taken notice? Rifling+?????=profit right?