Let's see those great cues that are old school style that never get old...

Show what you have,

Thanks,

John

Show what you have,

Thanks,

John

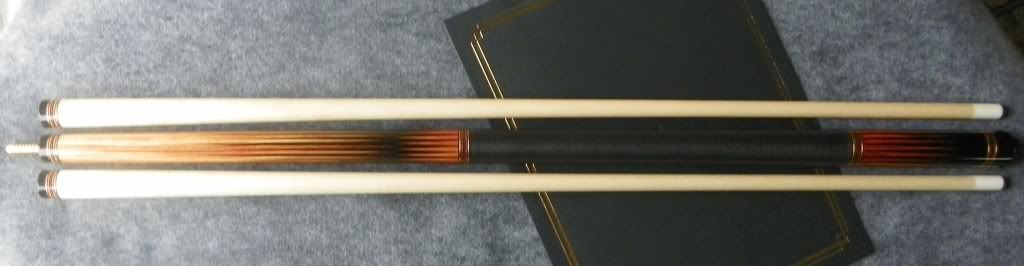

Ebony on Ebony.

Kenny M. told me this cue was all hand cuts before his CNC day. Maybe Mr. Murrell will make a comment on this cue.

Let's see those great cues that are old school style that never get old...

Show what you have,

Thanks,

John

Chris, aka Cueman brought it to my attention that when I say no CNC work there needs to be some clarifications. Here's what he had to say about it.

***************

I would like to clarify a couple of things. There will be almost zero true non cnc cues. For instance almost all joint pins are made CNC. The rub off transfers for the logo is cnc. I did the signature on the cue I presented with CNC as all my signatures are done on the cnc mill. But I did all the butterflies manual as well as the point cap inlays were done with a pantomill. Believe it or not a lot of people cut the v-grooves on their CNC mill and then hand fit the v points and veneers. You might want to clarify all points and inlays have to be done non CNC and are not including logos, joint pins, bumpers or ferrules.

Thanks,

Chris

***************

I agree with Chris' clarifications, what does everyone think??

John

I think this thread is only for cues built in 2011.

If it is for any year I definitely would like to change the cue I presented.

for me , in my little shop, cnc means can not compute

i dont know anything about it, i mean NOTHING, ZILCH, ETC.

dont plan to

im too old to start now

and the world ends next dec.21 anyways

my personal best of 2011

probably my best ever in my humble opinion

i really liked this cue!!!!! :thumbup:

hope steve does too

tikkler's blue butterfly cue in my sig line