Actually, I don't think so. I like the difference of opinions as long as its reasonably civil, as it has been. Everyone has made very good points. Do I take every word as a nugget of wisdom... we no. But, they all help me determine what I want to do, how I want to do it, or at least a good starting point. As other people have mentioned in other threads there's a difference between building in Arizona compared to say Florida. So what works for one might not work for another. This thread has been a big help getting me started with coring. I have a plan and even though I will probably modify it as the years go by I think it will work for me for quite a while.

Thanks to all

Bruppert,

Civility is a wonderful thing and should be the basis for peer check and review as well as the spirt of sharing in this forum. We all get smarter when we share ideas, whether we use those ideas or chuck them in the old memory bank. It is that simple.

Your AZ, FL comparison is what I feel is the prime directive for full coring cues. I myself build every style and design of cues including SPs, PJs, 4 pts, 5 pts and CNC floating point cues. Other than the SPs everything is cored.

I have shipped my full cored cues to many different regions of the world and I have never had someone say, "the cue is warped or has a slight wobble in it". I have read horror stories of Big Name cue makers who have built big dollar CNC design cues and when they shipped them the customer was not happy because the handle or forearm moved and the cue warped.

This is preventable. It is the nightmare scenario that I wish to avoid because I know how I would treat that customer. He would get is money back in exchange for the cue, Or I would build him a new one. Building cues for making money is very important but it is way down the list for my personal priorities.

When I am not working on cue orders I am advancing my CNC cue building skill sets because that is where one can get higher dollar values for their effort, IMO. By coring these cues I can sleep at night and this logic is so clear to me I can't understand why more people don't do it. Cultures and long standing habits are so ingrained in some people they don't see the forest for the trees and thats ok, one must do as they please.

If you are indeed embarking down this full coring road I can offer this info that may help you.

Purchase Kiln Dried wood for your stock and let that wood acclimate in your shop for at least a few weeks before coring it.

For two years I "acid beta tested" the full coring method and I broke all of the traditional methods for storing and handling stock on purpose. I did not hang them, left them lean up against outside walls in the winter and other things that would make A-Joint CMs puke. When I cored these pieces, glued them to dowels and tapered them my results were 90% + no warps.

Since going to 100% kiln dried stock and storing them in a proper fashion for my warpage is 0. I had 2 warp last year but they were not processed with Kiln Dried wood. Root Cause Defined,Lessons Learned and Corrective Actions Taken. The downside is that there are some woods like Tulipwood that is not kiln dried for some reason. Whats more after gluing up a forearm to the dowel I can turn it from 1 3/8" to .940 in less than ten minutes and the stability is not compromised. :duck:

Use laminated dowels, PH or maple only. These things must be treated with kit gloves like you treat your shaft wood and seasoning is your friend. With the laminate stock it is a little different and you can process them much faster. If your dowel is not running true do no use it.

Use GG or Accel water activated expansion poly glue to properly gap fill the annulus differential between the core and the dowel. If you use epoxy to glue the core it will work but both Darrin Hill and myself observed that about 1 or 2 out of ten will buzz from striation gaps especially if the glue soaks in to very fibrous woods. The expansion glue is where it is at and the half life on that stuff is measured in thousands of years.

Anyone who wants to criticize someone who does not use an A-Joint bolt on their cue is operating with a closed mind. No one is forcing them to change nor should they. Between you and I, I think full cored cues play lights out and offer a more consistent hit because of the construction method. I am not the guy who started this protocol and I don't know who did. What I do know is that I played with one of Steve Lomax's cues at my pool hall and loved it's feel, stat.

Weight an balance is a no brainer with full coring and you never have to even think about it until the cue is at final tapered size with 95% of woods used for cues. You can nail the weight and the balance point perfectly every time with very little effort. PM me when you are dealing with W&B and I will give you some important details i have learned and documented.

Good Luck Bruppert in the path you are traveling down and enjoy your journey. It should prove fruitful to your end results and goals.

To those who wish to throw stones without respect or civility, go for it, because it only helps feed more informercials you don't like. LOL. Anyone who disagrees with anyone here and does it with respect is ok with me and I love the feedback and would value their friendship as a peer any day.

Good Cue Making,

Rick

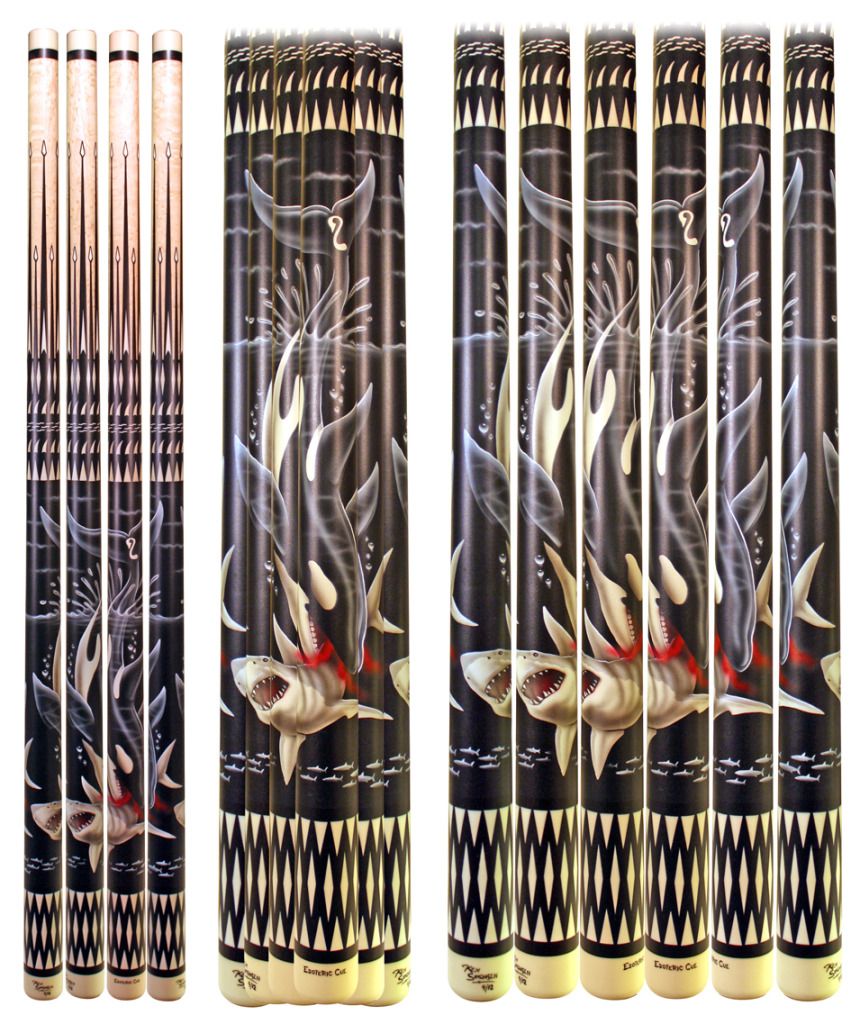

Here is a 12 pointer and my first Big CNC Cue. I built it this year on a full core set up. I put a lot of time in on this baby and I don't worry about the end user calling me dropping the W Bomb. ( Call me stupid for this logic ) I have been doing cue repair for over nine years and believe me I have seen wraped cues from some of the biggest so called Top Tiered CMs so many times it is a joke. If the handle or the forearm moves I don't care what kind of crafsmen you are, people don't like warped cues!!! Full coring virtually takes this situation out of the equation. At least with the procedures I follow and track performance thereof!!

Paying an Artist to render his talents which is a very expensive proposition added to my to my time and materials to build a cue like this, so full coring is my way to hedge the bet and a big time insurance policy on this capitol investment, for sure!! Why even risk a warp, it does not make any sense!

[/SIZE][/I][/B]