You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

dedicated coring lathe

- Thread starter jecues

- Start date

I have been thinking of buying a lathe just for coring so I can leave it setup, as it is very hard on my Hightower and is a little underpower. Does anyone having any suggestions on a direction to start researching. Thanks JIMM

buy a 1340 machine lathe and sell the Hightower to offset?

I have been thinking of buying a lathe just for coring so I can leave it setup, as it is very hard on my Hightower and is a little underpower. Does anyone having any suggestions on a direction to start researching. Thanks JIMM

Craigslist.

Look for old American steel with 1 3/8 spindle hole or bigger .

12 by 24 would be the minimum size you'd want.

Some of them can be had for 1K or if you look hard enough.

1Hp motor is a good start.

I core on my 12 by 36 Eisen.

Even that stalls a little if I drill too fast. The motor is 1 1/2 Hp 220V.

But, it sure drills nice . And not messy b/c I have a dust shoot near the chuck.

I core .700" , .758" and .883" as needed.

I can only imagine the stress on your saddle or tailstock on your lathe when you core .

Last edited:

If you are just going to do coring and leave it set-up then a 12 x 36 is your best bet. I would only purchase a Grizzly because you can get parts for them and quickly as Grizzly stocks most parts. With other lathes it is a job trying to get parts and buying used off Craigslist usually proves to be anything but a bargain.

If you want to begin working quickly, buy new. If you want to fix other people's problems and your time is worthless, then a used lathe is the way to go.

That's my 2 cents.

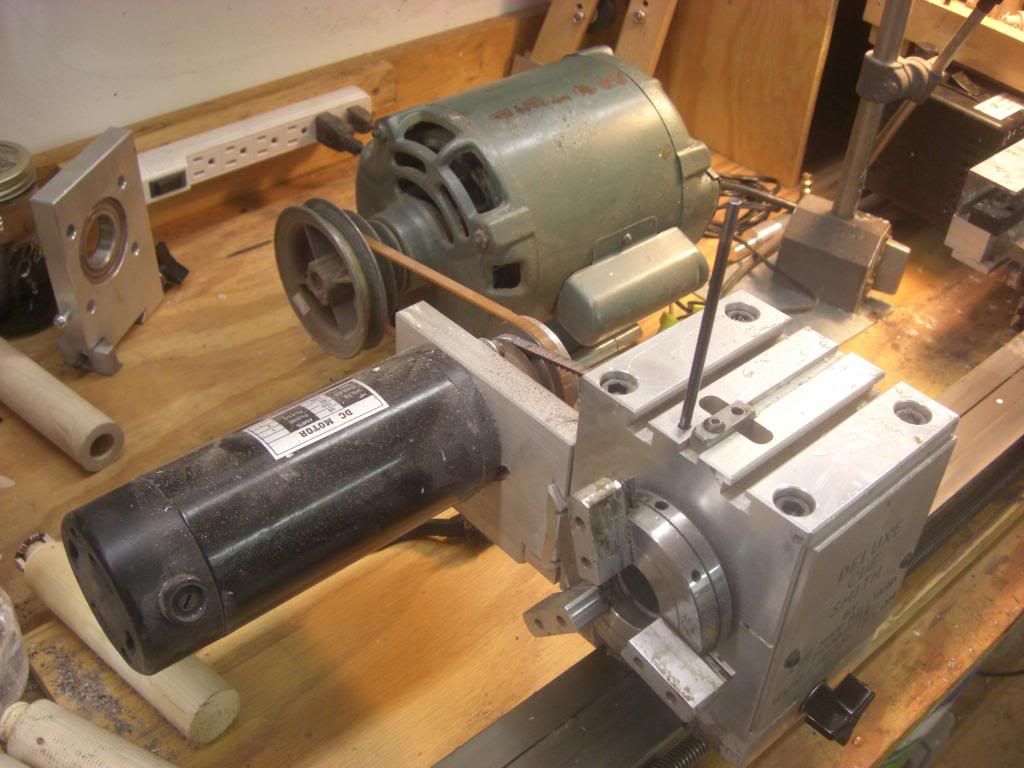

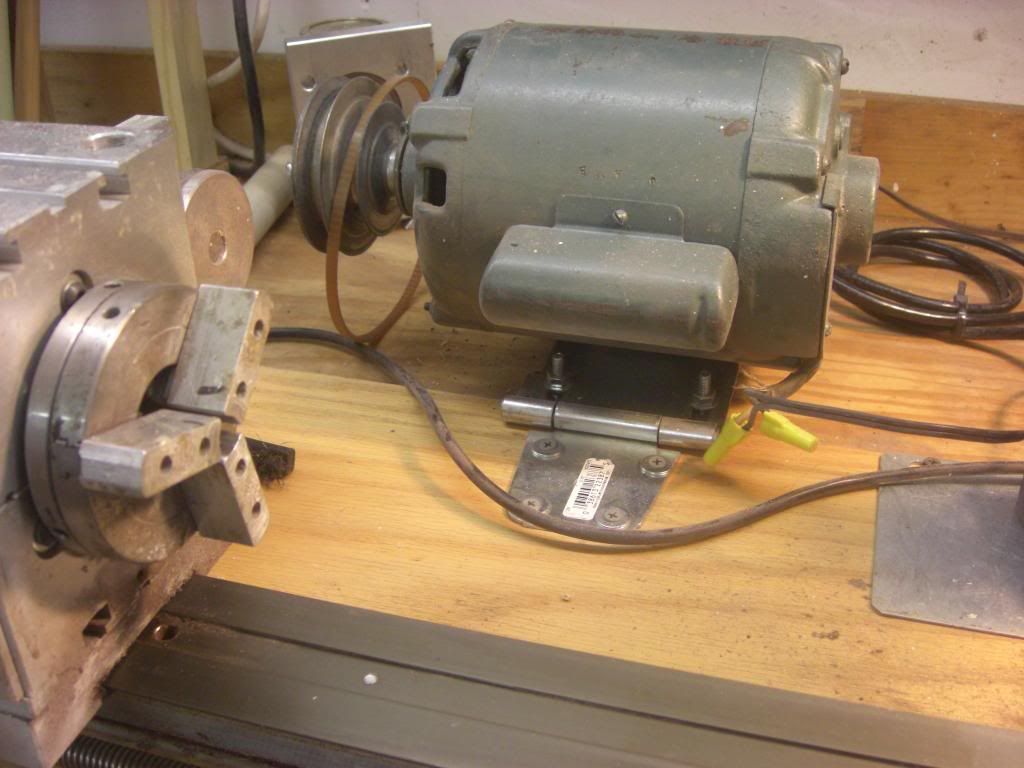

Here's my set-up

If you want to begin working quickly, buy new. If you want to fix other people's problems and your time is worthless, then a used lathe is the way to go.

That's my 2 cents.

Here's my set-up

Don't buy new if all you want is a lathe JUST for coring. That is just ludicrous. There are parts that can be broken that would make it DIRT cheap. What I meant is a 1340 can do everything that the Hightower can, plus core easily. Chris made a suggestion regarding motors that would make that moot.

PM me if you'd like my help finding a reasonable and suitable machine for about 1/4 the price of a new Grizzlly.

Replace that weak ass motor Joey

PM me if you'd like my help finding a reasonable and suitable machine for about 1/4 the price of a new Grizzlly.

Replace that weak ass motor Joey

JC

Coos Cues

If you are just going to do coring and leave it set-up then a 12 x 36 is your best bet. I would only purchase a Grizzly because you can get parts for them and quickly as Grizzly stocks most parts. With other lathes it is a job trying to get parts and buying used off Craigslist usually proves to be anything but a bargain.

If you want to begin working quickly, buy new. If you want to fix other people's problems and your time is worthless, then a used lathe is the way to go.

That's my 2 cents.

Here's my set-up

Might as well spend a little more and buy a 40 inch lathe then. Later on you will have more flexibility if you decide not to leave it set up for coring all the time. Plans change.

JC

Lathe

Amen to that. It just takes a few minutes to set up a 36 or 40" lathe for

coring.

Might as well spend a little more and buy a 40 inch lathe then. Later on you will have more flexibility if you decide not to leave it set up for coring all the time. Plans change.

JC

Amen to that. It just takes a few minutes to set up a 36 or 40" lathe for

coring.

Amen to that. It just takes a few minutes to set up a 36 or 40" lathe for

coring.

I agree with all this.

1. unless you get it for a grand or so, 36 inches is an unwise compromise.

2. I'd plan on coring, billet parting, and threading as well with a DEDICATED coring lathe. All things being equal, you shouldn't have to move anything once it's dialed in parallel with the ways.

3. Last 2 1340's I bought for 1600.00 and 1000.00. The 1600.00 was on Ebay and was exceptional until it fell over while trying to get it into my garage. The 1000.00 one is going to be my coring, billet parting, and threading lathe. That said, it's fully functional and could do everything else.

4. If you find a 1340 Morton, Lux Matter, ect I have parts.... :-(

5. With the exception of the bed, they seem identical. The Lux has a VERY beefy bed. They make the 1340 Microweily I have look like a toy.

Attachments

Heck, I have a 3/4 HP motor that used to be on my Logan lathe.

Comes with a switch. I'd sell it cheap if you pay shipping.

I was gonna use it for belt sander.

Comes with a switch. I'd sell it cheap if you pay shipping.

I was gonna use it for belt sander.

coring lathe

First off i wont get rid of my hightower lathe, I love this lathe just looking to cut down on setup time and have more power for coring i have about ai have a shop that is 35x60 i have plenty of room. All of you have very good ideas i have some info now to reasearch. Thanks for everyones input. JIMM

First off i wont get rid of my hightower lathe, I love this lathe just looking to cut down on setup time and have more power for coring i have about ai have a shop that is 35x60 i have plenty of room. All of you have very good ideas i have some info now to reasearch. Thanks for everyones input. JIMM

I would have to agree with buying the 13 x 40 if for only one thing. The title of the thread is, "dedicated coring lathe". Additionally, the OP reinforces the title by stating, "thinking of buying a lathe just for coring so I can leave it setup".

Therefore, why spend the extra money when all he wants is a lather for coring and the 36" is more than sufficient.

As far as buying new -vs- used -- if you have the time to search it out, pick it up, clean it, probably fix what is wrong with it and God only knows what else, buying used can at times be a nightmare with unforeseen obstacles.

Are you a cue maker or a used machinery expert and repair man? If you want to get right into cue making and your time is worth something then new is the only way to go. Of course, if you're on a budget, then used may be your only choice. Sometimes it's worth waiting and save up for the new equipment. You already have a Hightower, so make a few extra cues, sell them and you'll have the funds for the new equipment.

If you have to buy used, you go and search it out, run around town looking at machines only to find them in rotten condition.Then, if you're luck enough to find one and make the necessary repairs - how much time did you spend on all that? Time is money.

Additionally, many "cue makers" work in total chaos and are totally chaotic in their approach so listening to these 'experts' offering their opinions is a recipe and advise for failure.

You can buy used. You can buy new. If you decide to go new, take it ftom someone who has the experience with Grizzly. They work and they work well. They offer support. And most importantly, they stock the parts. We've had our machines almost 20 years and in that time we've made 4 repairs.

For repairs with Grizzly, we'd call them, explain the problem and a technician would call us back within a couple hours. He'd stay on the phone with us, we'd try different things and he'd narrow it down. Moments later we're paying for the purchase of the part and in 3 days we're up and running.

We had to repair one of our non Grizzly lathes. We called the supplier who was clueless. We got the runaround and finally a technician who said it was the 'discombobulator' and they didn't stock it. The part was $45 plus shipping from Taiwan. We were offered to pay $110 for overnight shipping. We opted for regular shipping and 30 days later we had the part. The reason we opted for regular delivery is that we purchased 4 of them as we saw the future and knew we'd wear the part out again. Plus, we weren't in any great rush as we have multiple lathes so it wasn't a big deal to wait for the part on this particular lathe. Since then we've replaced this one particular part twice. Two more to go. :grin:

And there is nothing like the smell of a new lathe. Kinda like buying a new car. :thumbup:

Conclusion: do what you think is best for you.

And to the OP -- great Logo! Best of luck to you.

Therefore, why spend the extra money when all he wants is a lather for coring and the 36" is more than sufficient.

As far as buying new -vs- used -- if you have the time to search it out, pick it up, clean it, probably fix what is wrong with it and God only knows what else, buying used can at times be a nightmare with unforeseen obstacles.

Are you a cue maker or a used machinery expert and repair man? If you want to get right into cue making and your time is worth something then new is the only way to go. Of course, if you're on a budget, then used may be your only choice. Sometimes it's worth waiting and save up for the new equipment. You already have a Hightower, so make a few extra cues, sell them and you'll have the funds for the new equipment.

If you have to buy used, you go and search it out, run around town looking at machines only to find them in rotten condition.Then, if you're luck enough to find one and make the necessary repairs - how much time did you spend on all that? Time is money.

Additionally, many "cue makers" work in total chaos and are totally chaotic in their approach so listening to these 'experts' offering their opinions is a recipe and advise for failure.

You can buy used. You can buy new. If you decide to go new, take it ftom someone who has the experience with Grizzly. They work and they work well. They offer support. And most importantly, they stock the parts. We've had our machines almost 20 years and in that time we've made 4 repairs.

For repairs with Grizzly, we'd call them, explain the problem and a technician would call us back within a couple hours. He'd stay on the phone with us, we'd try different things and he'd narrow it down. Moments later we're paying for the purchase of the part and in 3 days we're up and running.

We had to repair one of our non Grizzly lathes. We called the supplier who was clueless. We got the runaround and finally a technician who said it was the 'discombobulator' and they didn't stock it. The part was $45 plus shipping from Taiwan. We were offered to pay $110 for overnight shipping. We opted for regular shipping and 30 days later we had the part. The reason we opted for regular delivery is that we purchased 4 of them as we saw the future and knew we'd wear the part out again. Plus, we weren't in any great rush as we have multiple lathes so it wasn't a big deal to wait for the part on this particular lathe. Since then we've replaced this one particular part twice. Two more to go. :grin:

And there is nothing like the smell of a new lathe. Kinda like buying a new car. :thumbup:

Conclusion: do what you think is best for you.

And to the OP -- great Logo! Best of luck to you.

Last edited:

good luck with that

Last edited:

Coring lathe

Started doing research on the grizzly. For 2850 I can have a new lathe or I can buy a used lathe for a grand plus 250 shipping plus 6 hours to clean it up and probably 500 miscellaneous parts to get it to where I want it. I guess that I'm leaning towards joe suggestion of buying new. Not to mention grizzly has great support. As I have there band saw and table saw. Thanks for the honest opinions. Jimm

Started doing research on the grizzly. For 2850 I can have a new lathe or I can buy a used lathe for a grand plus 250 shipping plus 6 hours to clean it up and probably 500 miscellaneous parts to get it to where I want it. I guess that I'm leaning towards joe suggestion of buying new. Not to mention grizzly has great support. As I have there band saw and table saw. Thanks for the honest opinions. Jimm

Started doing research on the grizzly. For 2850 I can have a new lathe or I can buy a used lathe for a grand plus 250 shipping plus 6 hours to clean it up and probably 500 miscellaneous parts to get it to where I want it. I guess that I'm leaning towards joe suggestion of buying new. Not to mention grizzly has great support. As I have there band saw and table saw. Thanks for the honest opinions. Jimm

That spindle bore is 1.4 and where are you going to mount the motor?

You are going to need the same parts: rear chuck or something for support and a boring bar/bxa tool post and holders.

Started doing research on the grizzly. For 2850 I can have a new lathe or I can buy a used lathe for a grand plus 250 shipping plus 6 hours to clean it up and probably 500 miscellaneous parts to get it to where I want it. I guess that I'm leaning towards joe suggestion of buying new. Not to mention grizzly has great support. As I have there band saw and table saw. Thanks for the honest opinions. Jimm

You certainly won't regret it and all you need is a rear chuck, boring bar, air set-up and dust system. You'll be hours ahead and $$$$$ ahead by purchasing new not to mention the new lathe smell.

Good luck as you're on your way. Post some pics when it happens.

That spindle bore is 1.4 and where are you going to mount the motor?

You are going to need the same parts: rear chuck or something for support and a boring bar/bxa tool post and holders.

It's gonna be interesting to see how that rear chuck is going to help in coring 12"-13" pieces.

:scratchhead: Perhaps I'm a bit dumb, but I do not understand the need for a rear chuck. It's a coring lathe. A bearing rest would suffice. Heck, if the dowels were machined to fit snugly in the bearing rest, it would be more accurate than a rear chuck, anyway. Just a simple bushing that slips on the dowel & fits the ID of the spindle would work just fine. Cue making doesn't have to be complicated.

:scratchhead: Perhaps I'm a bit dumb, but I do not understand the need for a rear chuck. It's a coring lathe. A bearing rest would suffice. Heck, if the dowels were machined to fit snugly in the bearing rest, it would be more accurate than a rear chuck, anyway. Just a simple bushing that slips on the dowel & fits the ID of the spindle would work just fine. Cue making doesn't have to be complicated.

You haven't seen "custom rear chuck " for coring.

It's grabbing air during coring.

Last edited: