I have a number of people who have contacted with questions and I made a long reply to someone this morning so I thought I would post as sort of an FAQ. Perhaps this might help some who Is digging for answers.

Hi, Its been awhile since I sent you the email and I seen your reply not long ago so it's taken me awhile to respond.

BK Sure has been a while I certainly don't remember emailing you.[/B]

I have a old I think a A.E. Schmidt table that was made in the early 1900's. It looks very much like yours, I think yours is a Brunswick if I remember right.

BK Well, I have found information since that would indicate it is other than a Brunswick. I guess back when these tables were put out it was quite common for Brunswick dealers to swap the labels on other brands with their own label making their market dominance seem bigger. So, it would seem I have a table that was made by a competitor with a similar look to a Brunswick. I am told my table is perhaps a JE Came or Oliver Briggs. There were several manufacturers around at that time that were employees of Brunswick that broke out their own.

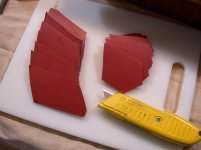

This table also has the wooden pocket blocks and I think I have those figured out, I'm buying the blocks for all the pockets from Classic Billiards.

BK I know for my table buying those blocks would have been a waste of money as they would have needed to be modified so much that I would have been better off to just make something up. Apparently when these tables were made they did not have a tool to actually cut that radius properly, (at least that is what I have been told). So I really had to fit those blocks for each corner radius as I went being careful to ensure I had the pocket shelf at a constant depth. If you look at my post Diary of an Antique Brunswick in the AZB forums you will see how I used a router with an attachment to cut the blocks level with the table. This was very accurate to the point where when done I could see where someone in the past had done sanding and sanded into the slate causing a little bit of a gully from the pocket shelf out into the slate. I am curious if Ken has recommended to you how to adhere these blocks?

The cost of the bolts I need and the barrel nuts is killing me because of the cost, found some nuts for 3.00 but that's all so I have to give into the 7.00 a nut price.

BK I know the feeling I needed one bolt and one nut by the time it got to my door it was 30 bucks. If I ever bought another table I would not consider it a minor issue to not have the fasteners because some lost the box they were in! There are other people who do table restoration work around the country and I am sure they all have some parts laying around but just don't have them up on a website. Perhaps with a few calls you could save yourself a few bucks. I know Mueller's has some bolts but make sure they will fit. They may even be one to call as they do some table restoration work I think.

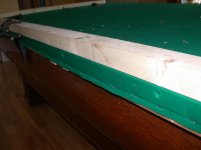

My main problem right now is what to do with all the staple and tack holes around the outside of the slate wood and also the areas where the pockets nailed into the ends of the rails mine is really chewed up and of course some of the wood is missing around the end of the rails where the pockets bolt in .

BK On the backer boards under the slate you can snap a caulk line a 1/2" back from the edge. Set your skill saw to a cutting depth very close to the slate like maybe an 1/8" or a little less and cut that edge off. Get some poplar wood and rip off 1/2" strips and just nail them on with some glue. Now you have some virgin edge to staple to.

My rails were a different story due to the balls hitting the facings the ends of my rails looked like a fence post that had been hit with a sledge hammer too many times. Also my pocket openings were well over 5" with quite an angle in the mouth of the pocket so I trimmed back the end of the rail changing the angle and then built it back out using plywood which was nailed and glued. As far as the areas where the pockets were nailed to I didn't really have to do anything.

As of now I'm using flexible epoxy for the areas where you have to tack into, as said this epoxy is flexible enough to take the tacks and a harder epoxy for the other parts of the rails. What did you do to take care of this. I had thought of doing that but ended up just not doing that repair and everything was fine.

Finally your table looks great and I hope mine turns out to look half as good. Thanks Dennis

BK Well everybody that plays on it loves it. The pockets are a bit tight but fair. When I recloth the table the only modification I will make is to shorten the pocket shelf as they are just too deep to the point that if a ball is hanging the cue ball just does not go in the direction you might expect because of the nipples. The other thing I am planning on is replacing the rubber. The rubber I used is the Championship Tour Edition and is just does not really bounce well. The cloth I used was very reasonable and a good value but I have had some issues with it so next time it is Simonis for me.

I had a lot of time into my table between the research and the extent and quality I was trying to obtain. I have talked to a couple of restoration pros and they have said that more work goes into making the table play correctly and correcting mistakes made over the years than anything thing else they do.

I hope all this helps and good luck with your project.