I was having trouble getting really good pressure on rings and things when using my hightower lathe. I know that you guys with big metal lathes can crush a cue with one of those. So I made a fixture that will put things together with real pressure. Remember pressure is no substitute for proper fit up of parts. Too much pressure can squish too much glue out of the joint but I don't get any glue lines anymore.

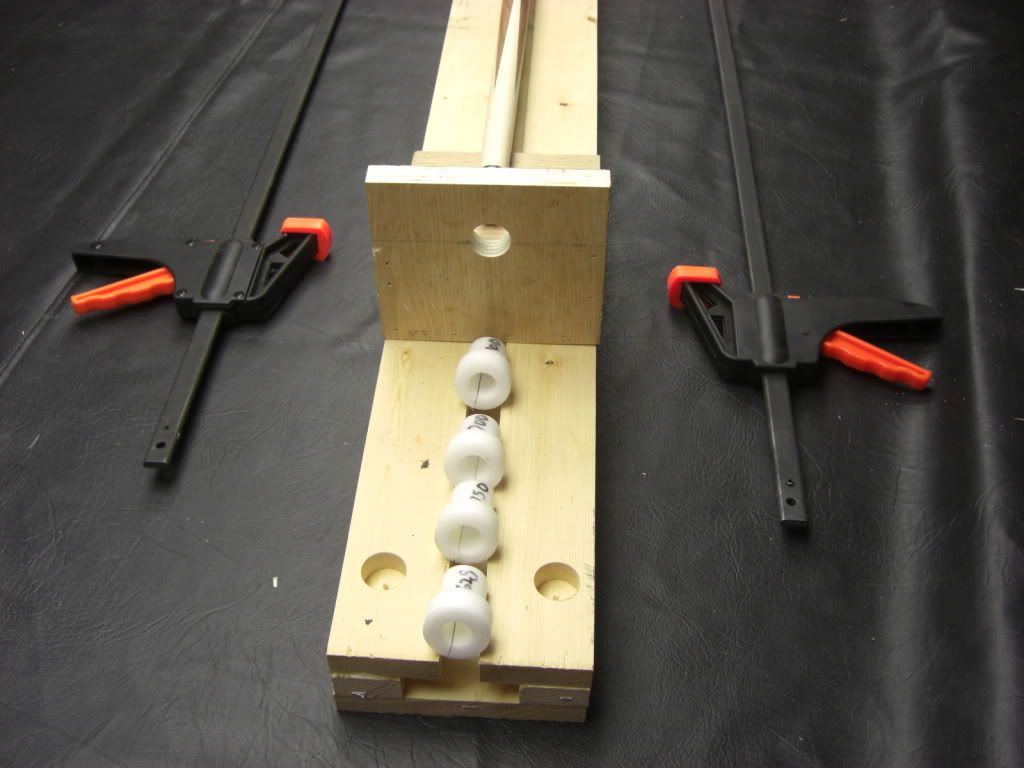

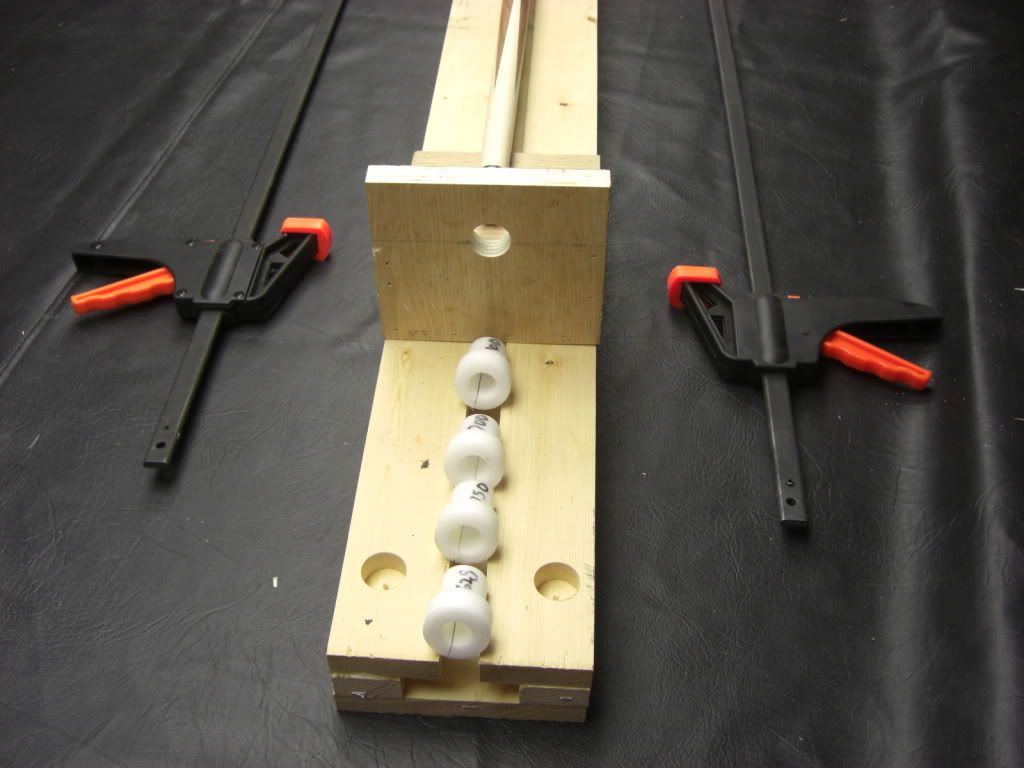

I made the inserts from delrin to fit the different sizes of dowels that I use. They are slit length wise in the band saw and I lightly wipe them with cue wax so they don't stick to the epoxy and they will come off easily.

It is glued together with tite bond and a few shots from my brad nailer.

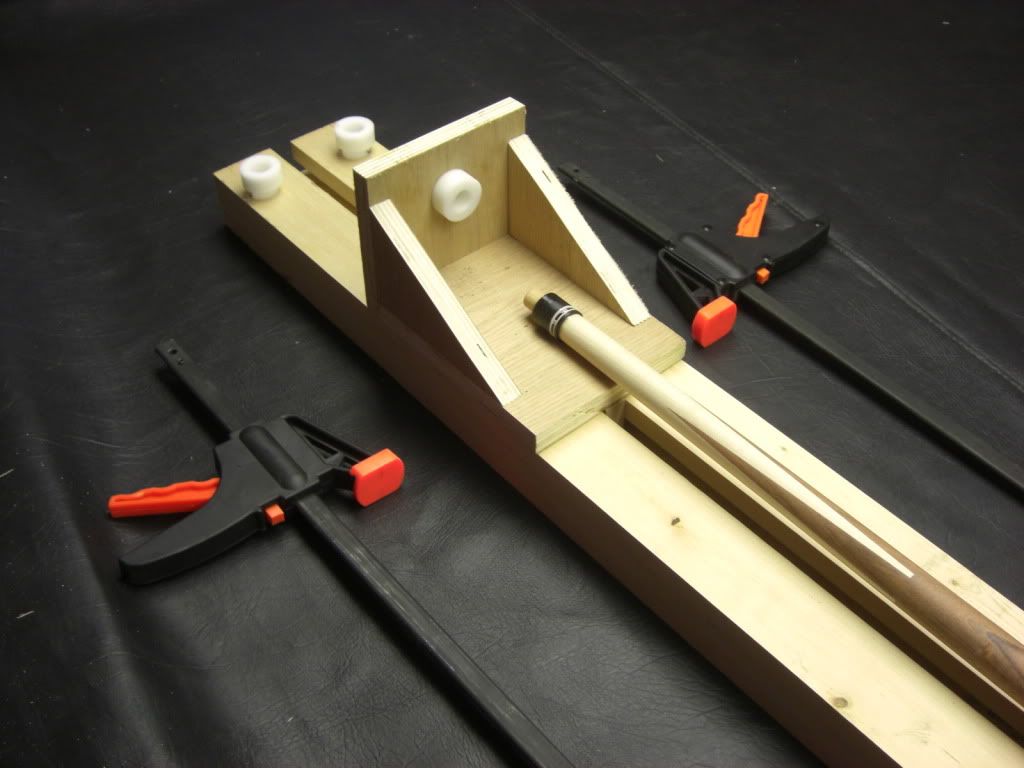

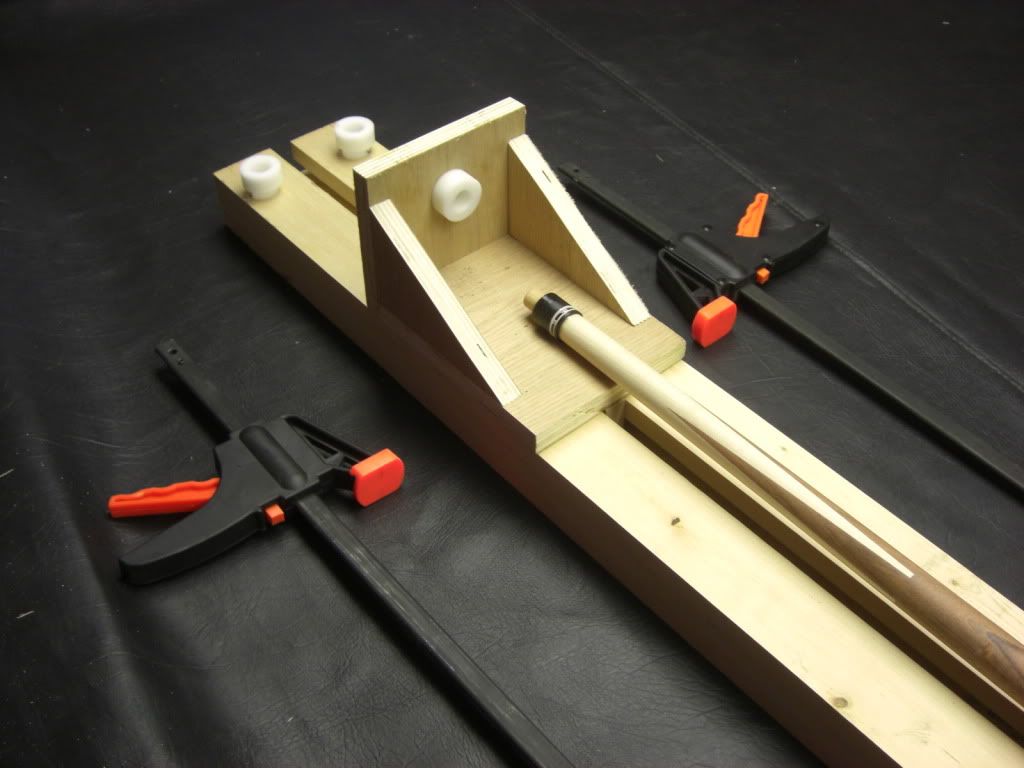

The full fixture with a cue in it,,,,

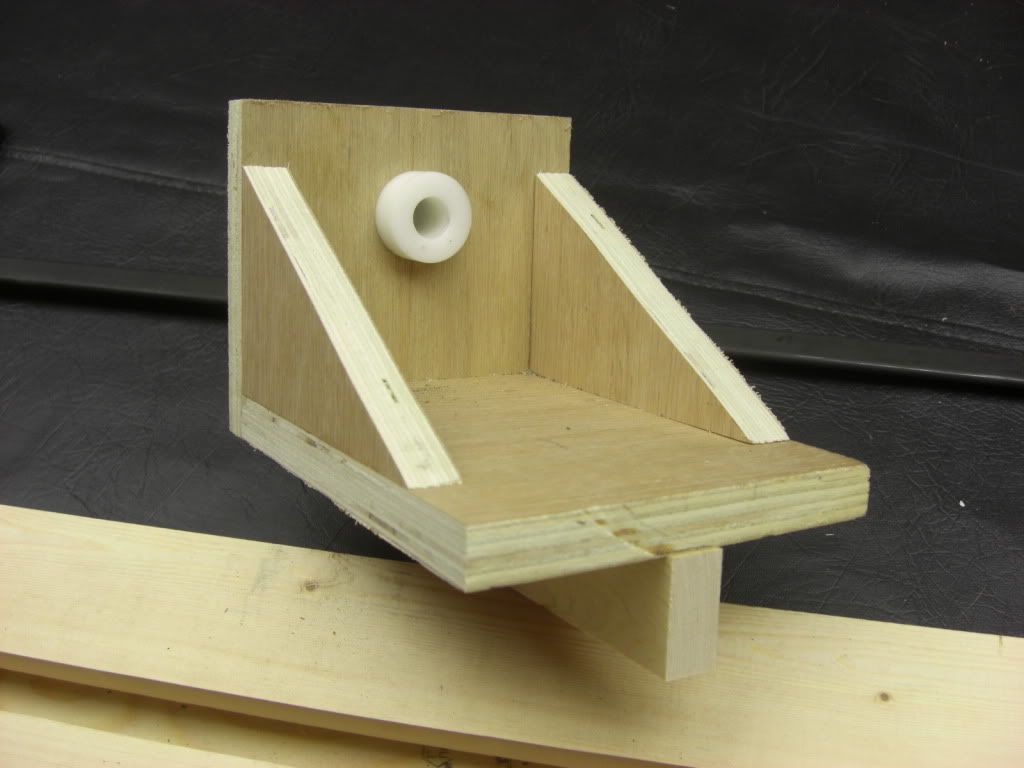

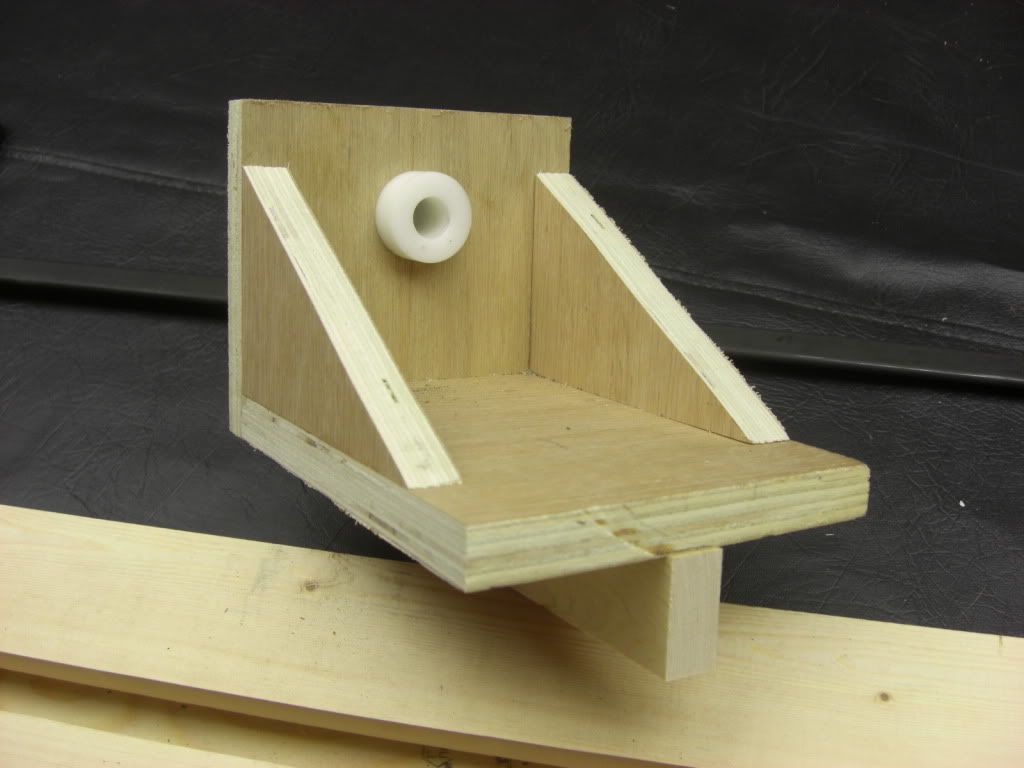

The solid end that does not move.

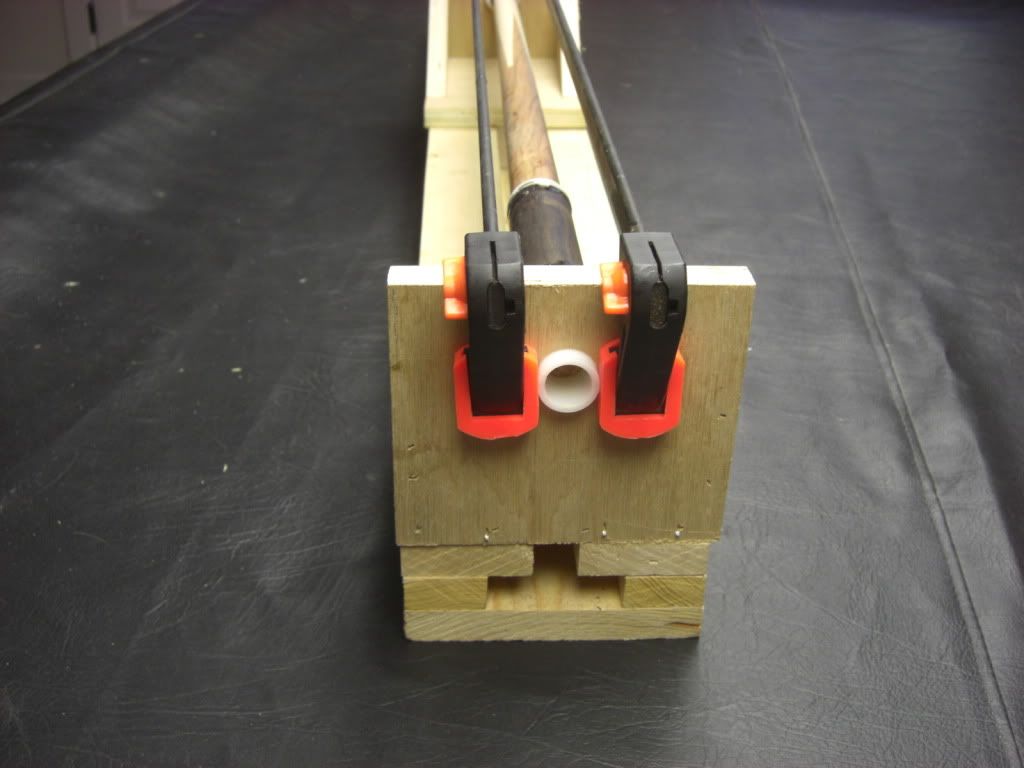

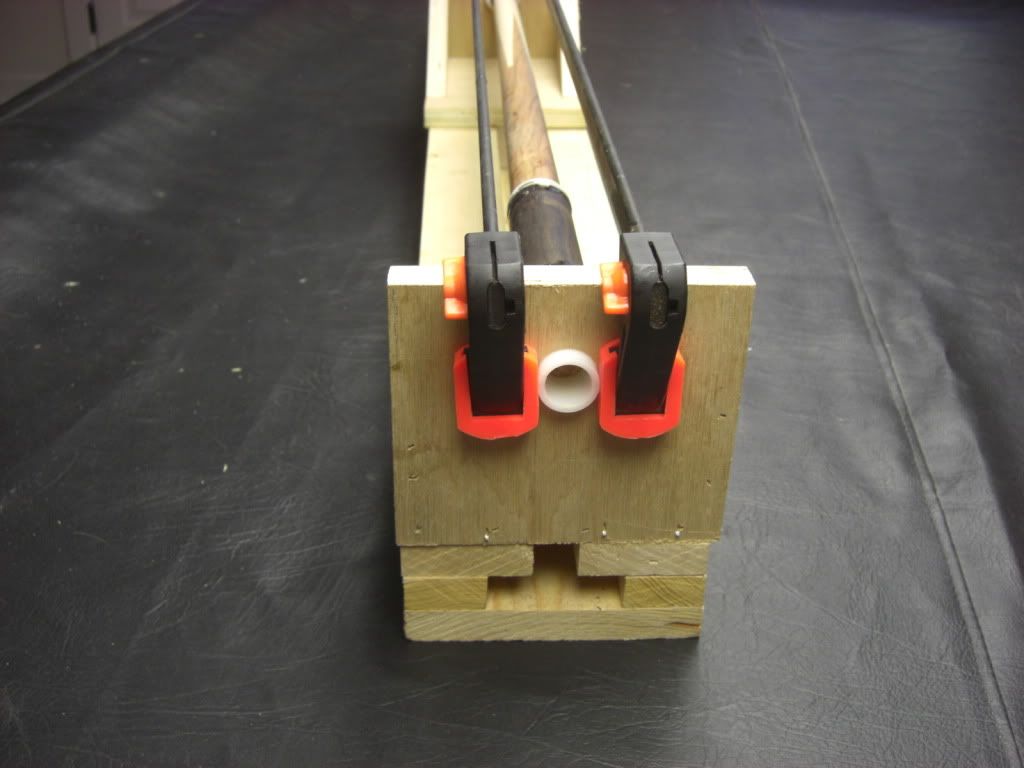

The end that slides.

The delrin inserts that match the dowel size.

The sliding end.

I use 2,,,,,, 36 inch bar clamps from HF - $9 each.

The delrin inserts slip into a 1 in hole from a forstner bit.

If anyone wants measurements, PM me for a sketch.

Kim

I made the inserts from delrin to fit the different sizes of dowels that I use. They are slit length wise in the band saw and I lightly wipe them with cue wax so they don't stick to the epoxy and they will come off easily.

It is glued together with tite bond and a few shots from my brad nailer.

The full fixture with a cue in it,,,,

The solid end that does not move.

The end that slides.

The delrin inserts that match the dowel size.

The sliding end.

I use 2,,,,,, 36 inch bar clamps from HF - $9 each.

The delrin inserts slip into a 1 in hole from a forstner bit.

If anyone wants measurements, PM me for a sketch.

Kim

Last edited: