It may be the camera angle, but in the end shot pic, the hole looks to be off center. I could see this resulting on more stress on one side of the shaft. On a hard shot this might cause the damage you experienced. Just a guess on my part. Also, this happened in November as indicated by the first post. Could the shaft have been in a cold car before this happened? A guy I know here snapped his shaft on a break shot right after he started playing. It was winter and he had left his cues in his car for a day beforehand.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is this Ferrule Cracked? Maybe a Little Bondo Wood Filler?

- Thread starter Cardigan Kid

- Start date

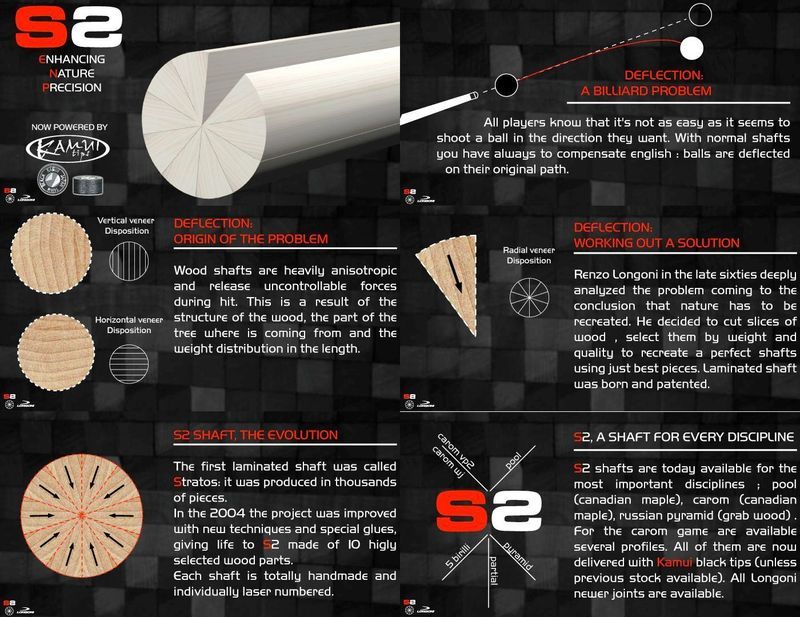

I thought the laminated shafts looked like this:

View attachment 422827

This scares me:

View attachment 422829

The pie laminated shafts do look like that, at least before their centers are hollowed out as is the case with the first few inches of Predator shafts and others. There are also other lamination methods in use though, such as flat lamination used by quite a few cue makers (plywood is flat laminated), and the OB cues lamination method which is best to go look up a picture of on their website as it is a bit complicated and hard to describe.

If I am understanding you it sounds like you are scared of the second picture because it has been hollowed out, which is actually pretty common in low deflection shafts (although in this particular case it was just done to install a new tenon I believe so it was "filled back in" with a wooden dowel which was left hanging out to make the new tenon with). What is concerning to me is what the previous poster pointed out, that the hole is quite a bit off center (so presumably the tenon will be just as off center unless enough material is removed to get in centered in which case a small and weak tenon may be left and would be the new concern).

It may be the camera angle, but in the end shot pic, the hole looks to be off center. I could see this resulting on more stress on one side of the shaft. On a hard shot this might cause the damage you experienced. Just a guess on my part. Also, this happened in November as indicated by the first post. Could the shaft have been in a cold car before this happened? A guy I know here snapped his shaft on a break shot right after he started playing. It was winter and he had left his cues in his car for a day beforehand.

You are correct. The hole was definitely off center.

The camera lens on my phone wouldn't focus on it unless I had it at an angle a bit.

And the shaft was in a room temperature basement for the short time I was playing with it. Never in a frozen car or humid environment, and I agree the elements do a number on wood.

Thanks, I appreciate your insight.

I think I just underappreciate the power of engineered wood.

I think I just underappreciate the power of engineered wood.

The pie laminated shafts do look like that, at least before their centers are hollowed out as is the case with the first few inches of Predator shafts and others. There are also other lamination methods in use though, such as flat lamination used by quite a few cue makers (plywood is flat laminated), and the OB cues lamination method which is best to go look up a picture of on their website as it is a bit complicated and hard to describe.

If I am understanding you it sounds like you are scared of the second picture because it has been hollowed out, which is actually pretty common in low deflection shafts (although in this particular case it was just done to install a new tenon I believe so it was "filled back in" with a wooden dowel which was left hanging out to make the new tenon with). What is concerning to me is what the previous poster pointed out, that the hole is quite a bit off center (so presumably the tenon will be just as off center unless enough material is removed to get in centered in which case a small and weak tenon may be left and would be the new concern).

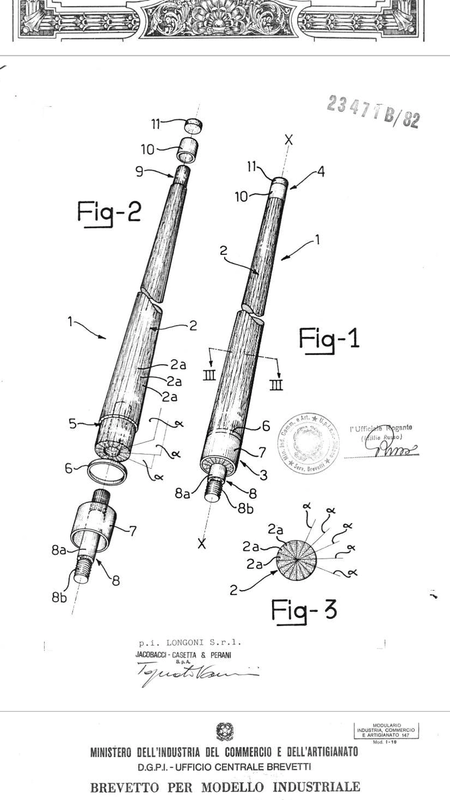

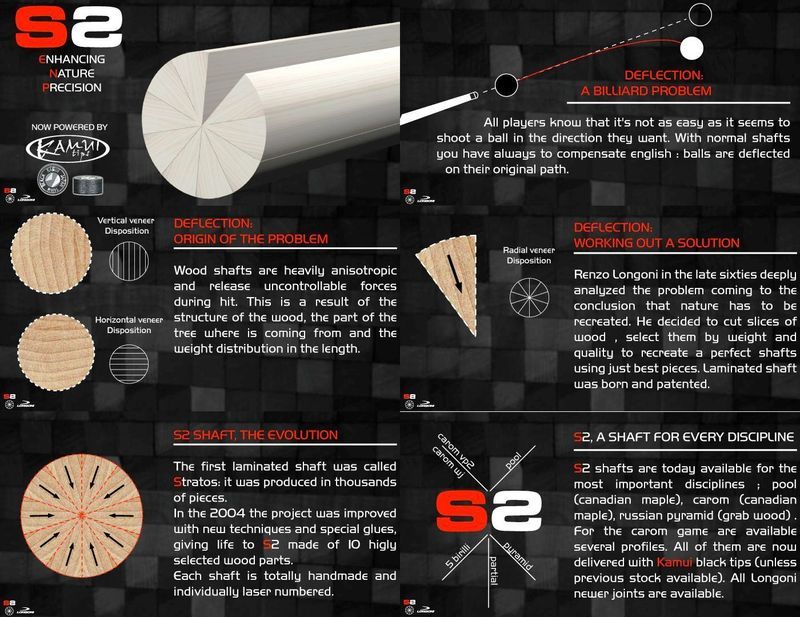

That was a big revelation into the Longoni S2 shaft.

I was told by the dealer rep that they did not hollow out their shafts like predator, instead utilizing a spliced construction with no void or filler material.

So when goinginto the damaged area to try to construct a new tenon-the end just popped off and to our surprise, there's a three inch hollow void in the shaft. The used a mini dowel with the tenon inserted as a plug (and off center as the picture shows).

Dan would end up installing a new wooden dowel taking up the entire off center void, and creating a new tenon from that (only this time he would have it centered). Also he showed me how if correctly done, there is no way you should have a small void between the tenon and the ferrule top.

It was quite the learning experience. Again, no comment from Longoni, maybe due to patent infringement on other cue makers low deflection methods?

Still on their site, nothing is mentioned about a hollow void in their shafts.

Last edited:

This is been one of the best post I've read on this forum. Very informative and I actually think I learned something. Thanks for the story and the good pictures.

That's what is so valuable about this forum.

The learning never stops.

This was all a learning experience for me, so I'm glad I could share it with you.

Play well!

This is not really engineered wood at all. All their "engineering" process allows them to do is use wood that would otherwise be unusable as shaft wood. Sure it allows them to keep weight down by using lighter wood, thus creating lower squirt, but it does so at the expense of structural integrity. If that wasn't bad enough, they then go ahead and drill out most of this wood creating a thin walled hollow section full of glue joints waiting to fail. I'm not at all convinced that they even consulted any real engineers during this " engineering" process. I have never seen a solid maple shaft fail during normal use in a pool hall. I have seen many "engineered" shafts fail. In fact I have seen this exact type if ferule failure a dozen times or more, not to mention how many glue joint failure cracks I have seen.

Last edited:

That was a big revelation into the Longoni S2 shaft.

I was told by the dealer rep that they did not hollow out their shafts like predator, instead utilizing a spliced construction with no void or filler material.

So when goinginto the damaged area to try to construct a new tenon-the end just popped off and to our surprise, there's a three inch hollow void in the shaft. The used a mini dowel with the tenon inserted as a plug (and off center as the picture shows).

Dan would end up installing a new wooden dowel taking up the entire off center void, and creating a new tenon from that (only this time he would have it centered). Also he showed me how if correctly done, there is no way you should have a small void between the tenon and the ferrule top.

It was quite the learning experience. Again, no comment from Longoni, maybe due to patent infringement on other cue makers low deflection methods?

Still on their site, nothing is mentioned about a hollow void in their shafts.

I always understood, atleast from a patent perspective that Longoni is just a high end predator. Are they not a brother/sister type operation?

In terms of pie cutting, pie splicing and boring out the Center is a terrible thing unless splines are used as reinforcements. Would you want to spin a snare drum on a late joined simply by wood without splines? I've seen someone try it and they ended up with pieces of wood go in under his shoulder and out the other side.

Sent from my iPhone using Tapatalk

Last edited:

I always understood, atleast from a patent perspective that Longoni is just a high end predator. Are they not a brother/sister type operation?

In terms of pie cutting, pie splicing and boring out the Center is a terrible thing unless splines are used as reinforcements. Would you want to spin a snare drum on a late joined simply by wood without splines? I've seen someone try it and they ended up with pieces of wood go in under his shoulder and out the other side.

Sent from my iPhone using Tapatalk

^^^^^^^^^^^^^^:thumbup:^^^^^^^^^^^^^^^

This is not really engineered wood at all. All their "engineering" process allows them to do is use wood that would otherwise be unusable as shaft wood. Sure it allows them to keep weight down by using lighter wood, thus creating lower squirt, but it does so at the expense of structural integrity. If that wasn't bad enough, they then go ahead and drill out most of this wood creating a thin walled hollow section full of glue joints waiting to fail. I'm not at all convinced that they even consulted any real engineers during this " engineering" process. I have never seen a solid maple shaft fail during normal use in a pool hall. I have seen many "engineered" shafts fail. In fact I have seen this exact type if ferule failure a dozen times or more, not to mention how many glue joint failure cracks I have seen.

You're exactly right.. You can label it as "engineered" but it's not. Engineered would be crossbanding the layers so each layer would resist the other. The engineering part kicks in using materials with specific adhesives and using substrates that are holding the correct moisture content to avoid expansion.

IMO

OB>Longoni, so good move there OP

I owned several Longoni shafts. The PRO 2's are good, but the S shafts are terrible. I could feel the pie lamination's coming apart, and the ferrule material shrunk.

It makes me cringe inside when I see people re-tapering shafts. No doubt the thinner sidewalls contributed to this issue. Regardless of that the ferrule install was sloppy, as is the off center hole.

Thanks for sharing the pics and story! It's good to see and learn this sort of thing.

OB>Longoni, so good move there OP

I owned several Longoni shafts. The PRO 2's are good, but the S shafts are terrible. I could feel the pie lamination's coming apart, and the ferrule material shrunk.

It makes me cringe inside when I see people re-tapering shafts. No doubt the thinner sidewalls contributed to this issue. Regardless of that the ferrule install was sloppy, as is the off center hole.

Thanks for sharing the pics and story! It's good to see and learn this sort of thing.

I repaired a broken ferrule on a S2 shaft last week. There was a slight gap between the ferrule an the tennon, very little glue to take off and the threads on the tennon was almost non existent.

I cleaned up the ferrule and live tooled new threads. I used the new Tomahawk ferrule material, came out real nice.

I have repaired Predator shafts in a similar way to the shaft in the pictures, it seems to work fine. Why he didn't care to center that shaft before working on it beats me though...

I cleaned up the ferrule and live tooled new threads. I used the new Tomahawk ferrule material, came out real nice.

I have repaired Predator shafts in a similar way to the shaft in the pictures, it seems to work fine. Why he didn't care to center that shaft before working on it beats me though...

I repaired a broken ferrule on a S2 shaft last week. There was a slight gap between the ferrule an the tennon, very little glue to take off and the threads on the tennon was almost non existent.

I cleaned up the ferrule and live tooled new threads. I used the new Tomahawk ferrule material, came out real nice.

I have repaired Predator shafts in a similar way to the shaft in the pictures, it seems to work fine. Why he didn't care to center that shaft before working on it beats me though...

Dan was wondering the same thing when he saw it. No excuse for not getting everything centered before boring out the void.

It was remarkable to watch Dan work and correct the issue. When he was done everything was centered up for the ferrule.

I also had Dan replace the ferrule on the backup S2 shaft I had. This one also had a gap, but not as bad as the damaged one. Also both tennons were not threaded. Dan threaded the tennon and installed a more durable ferrule.

You folks who repair cues are a credit to the sport. Thank you for all that you do.

Hi Members,

It's not often that I read through a complete thread without seeing a bunch of misleading information or half truths.

This tread was enjoyable to read and had honest information form people who actually know what there talking about.

I just wanted to say thanks for being genuine and for sharing your educated points of view

Appreciate you all very much,

It's not often that I read through a complete thread without seeing a bunch of misleading information or half truths.

This tread was enjoyable to read and had honest information form people who actually know what there talking about.

I just wanted to say thanks for being genuine and for sharing your educated points of view

Appreciate you all very much,

Hi Members,

It's not often that I read through a complete thread without seeing a bunch of misleading information or half truths.

This tread was enjoyable to read and had honest information form people who actually know what there talking about.

I just wanted to say thanks for being genuine and for sharing your educated points of view

Appreciate you all very much,

:thumbup:

Great thread.

.

From the pictures, it is difficult to see that the original (broken) ferrule was threaded. Can you please confirm this is the case, or was it a slip-on with teeth angled to grab the wood?

Also, dealing with the Italian way of doing business on some transactions can be very frustrating. Even more frustrating is that you cannot assess penalties or interest on overdue bills or delinquent product. We dealt with this constantly when I was in Microsoft procurement.

Also, dealing with the Italian way of doing business on some transactions can be very frustrating. Even more frustrating is that you cannot assess penalties or interest on overdue bills or delinquent product. We dealt with this constantly when I was in Microsoft procurement.

From the pictures, it is difficult to see that the original (broken) ferrule was threaded. Can you please confirm this is the case, or was it a slip-on with teeth angled to grab the wood?

Also, dealing with the Italian way of doing business on some transactions can be very frustrating. Even more frustrating is that you cannot assess penalties or interest on overdue bills or delinquent product. We dealt with this constantly when I was in Microsoft procurement.

Yes, that tennon was a smooth tennon with a threaded ferrule. Also the unbroken one I had the ferrule replaced was the same as well. I was told that this is not necessarily a bad thing provided that the tennon length matches the depth of the ferrule and that enough epoxy/glue (I forgot the proper term used) to fill the voids between the threads and wood.

On the broken shaft in the photos there was the slightest traces of glue from the lower threads and the base of the ferrule. Nothing at all in the top face of the tennon.

But as Dan displayed (and I wish I took photos of the process) threading a tennon is an extra step that ensures the quality of the ferrule, and he made it look quite easy with the proper tooling and decades of experience.

And I absolutely concur on the Italian business transactions and with the information you provided, we see that it extends to other areas of business other that cue making.

I've played with Longoni Carom cues for years, Have never had an issue. I played with the, 'Pro 69' shaft.

Of all the mass produced carom cues, the Longoni's have always been the most solid for me.

Of all the mass produced carom cues, the Longoni's have always been the most solid for me.