I guess being honest and telling the truth is funny right?

[...]

It has nothing to do with "being honest and telling the truth". It has to do with incorrectly using words that really don't fit the context, are spelled phonetically, are chosen because they sort of sound like the word you think you want to use, or are archaic and only meant to try to make yourself sound a lot smarter than you are.

And that is indisputably funny. I mean, pretty much everything about you is funny, but that particular failing of yours is especially funny. Downright hilarious, actually

For example, in one of your recent dissertations about yet the latest skill you claim to have mastered you wrote:

scdiveteam said:"I took two college classes in Dimential Metroloygy."

"Dimential Metroloygy"? What the hell is that? Do you mean dimensional metrology?

AND

scdiveteam said:"It also gained me axis to the clean room inspection lab."

"Axis"? It gained you "axis"? I guess you mean access...?

Face it Rick, you're kind of semi-literate, and I suspect you know this. So you try to compensate by using words and phrases that you aren't really familiar with, but think make you sound intelligent. The problem is, even if you did know how to use them in a sentence it still comes off as idiotic.

To use an example that has been addressed many time before, where any normal cuemaker might say, "I glue the joint pin in with a high-quality epoxy", YOU write:

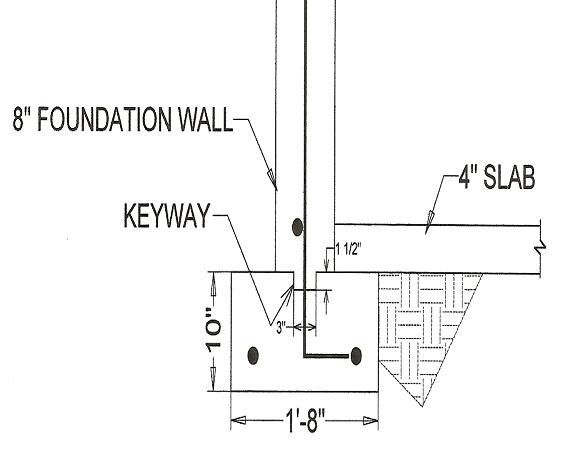

scdiveteam said:" 6,500 psi epoxy also and the structural encapsulation within the annulus with the threads acting a keyway anchorage embedment zones." [...]

Let's break that little bundle of bullshit down, shall we?

"6,500 psi epoxy" What exactly does that mean, Rick? Are you providing the psi rating for your epoxy's compressive strength, tensile strength, flexural strength, or bond strength? These are the four aspects of epoxy that are measured and rated, and they are very different from each other. More importantly, who do you think gives a damn about any of the psi ratings for your epoxy? It's not like you formulate it yourself.

"structural encapsulation" Really, Rick? Do you think no one realizes that when you have a sloppy, oversize cavity the epoxy is going to goosh all around the pin and harden in place?

"annulus"? I get what you're trying to describe, but from a mechanical engineering aspect "annulus" is not the right word - it's simply not used to describe any part of a machine thread. You could say "minor diameter" or "thread root", but "annulus" is simply incorrect.

"keyway anchorage embedment" Oh my God. Why not just use the word "anchor" and be done with it?

You constantly accuse others of "obfuscation". For those who are not completely familiar with that word, we go for a moment to Wikipedia:

Wikipedia said:Obfuscation (or beclouding) is the hiding of intended meaning in communication, making communication confusing, willfully ambiguous, and harder to interpret. The word comes from Latin obfuscatio, from obfuscāre ("to darken"), from ob ("over") and fuscāre ("to make dark"), from fuscus ("dark").

Your writing is the very essence of obfuscation, and the rest of us find it irritating - but funny. Very, very funny. You are the very embodiment of Oswald Bates, and for that I thank you.

TW

Last edited: