You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

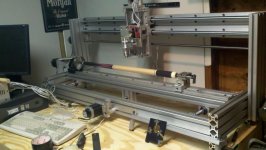

my inlay machine

- Thread starter Trent

- Start date

Heres a pic of my inlay machine and new cue im working on.

View attachment 201780

View attachment 201782

View attachment 201783

View attachment 201784

Congratulations

Sent from my iPhone using Tapatalk

Yeah but you need more travel.

Nice setup Trent.

Nice setup Trent.

Last edited:

I could swear that I've seen that machine some where before  :thumbup:

:thumbup:

Sweetness! :thumbup:

Joe

Joe

Nice setup!

Mines bigger.

I could swear that I've seen that machine some where before:thumbup:

i confess Joe is the father of my baby i helped him concieve it and now im trying to raise it lol

thanks joe

murray we all know yours is bigger

but its how you use it that counts lol

Yeah but you need more travel.

Nice setup Trent.

Maybe he needs the travel to inlay a 70" cue for Earl.

Scott

Maybe he needs the travel to inlay a 70" cue for Earl.

Scott

someone has to corner the market!!:thumbup:

What do you think of the bdtools 4th axis indexer? I asked about it on here last year and got zero replies from anyone that had used it. It would be a bolt on upgrade for me as I am already using a Taig headstock with manual indexing right now.

That's an interesting spindle motor. What are you running it with? Are you a RC guy?

That's an interesting spindle motor. What are you running it with? Are you a RC guy?

theres a power supply next to the machine that runs the motor and i was a RC car guy and now that we have a new indoor track i might get back into it. but thats the motor the wolfgang came with, thing screems and has a good bit of torq (sp)

i had one of the older one on a panto and it worked great this one is quit a bit beefier so i imagine it will work fine. in the future ill upgrade but for now it will do the job.

I was gonna ask the same question looked Like an RC motor to me too. I have been looking at that larger spindle Myself. Can you still only get one collet for them?

Greg

I think so.

I think so.

Thanks, I use 2 different shank sizes, so for me that's the only drawback. I would like to have one on My panto though, and then swap It over when I get a new machine going. It's really a matter of money though, I guess I could get the same size mills in 1/8 too, just more expensive.

Great design , very nice . Jim