You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simonis Std Green 860 -- their website Fails so I ask the experts

- Thread starter OTLB

- Start date

So are you saying a sideways stretch of 2 on a Diamond box is the max for. 760

You could push it to 2 1/4" but I wouldn't recommend it, but yes

and what was the length?

I don't measure the length, I stretch the first end about 80% of what I could stretch it, then I stretch the opposite end as tight as I can, then restretch the first end as tight as I can. You see John, you can't put a stretch mark on an end to end stretch before it's stretched from side to side, because when it's stretched side to side first, the ends bow inward towards the side pockets. So if I measured a 2" stretch for the ends, by the time the cloth is stretched side to side that 2" end stretch would require another 2" stretch just to get back to where I marked it for the first 2" stretch, meaning a 4" overall stretch end to end.

Glen

Well done

Nice work realkingcobra those are perfect.Rep to you on knowing your sh*t!:thumbup:

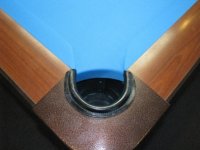

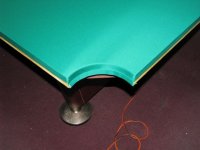

When you can do pocket work like this ALL the time, on any kind of table with backing under the slate, why look for a better way of finishing off the pockets?

View attachment 86479

View attachment 86480

OTLB, post some pictures of the pocket work you did on your GC4 Snooker table, I'd be interested in seeing how you've finished off the pockets on that table:wink:

Glen

Nice work realkingcobra those are perfect.Rep to you on knowing your sh*t!:thumbup:

RKC can you show how you install without any staples on the sides of the slate? Very clean installation.

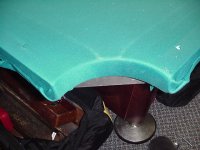

Here, this is a picture of the backer on Fatboy's Gold Crown 5, that has never been stapled.

Attachments

OTLB

Banned

here is my pic. of course yours has staples, thats how you do the pockets. Actually the pocket area is the best for glue, the sides of the slate liners can be done over and over etc by stapling. Its the pockets that take alot of abuse from staples and adding more will only degrade the liner in that area and be the cause of problems in the future.

Attachments

Last edited:

here is my pic. of course yours has staples, thats how you do the pockets. Actually the pocket area is the best for glue, the sides of the slate liners can be done over and over etc by stapling. Its the pockets that take alot of abuse from staples and adding more will only degrade the liner in that area and be the cause of problems in the future.

It's not the staples that tear up the MDF/Particle board backer under the pockets

Glen

PS. My pockets and sides of the slate still look much cleaner than yours

Last edited:

Interestingly to me would be the scenario of knowing what a given mechs stretch was before and then comparing it to my tac strip method with the same guy. Regardless though I would love to hear arguments why stetching cloth from both sides with my tac strip method is not as good as pulling cloth from only one side.

When you start from one side and pull to the other, you have less variable. You know that the grain of the felt should be straight and true down that first edge. You mark a line on the opposite side of the felt at the distance you plan to stretch the cloth, and you pull the cloth to that line. Using this method, you know that the grain of the cloth will be as close to straight as possible, without much hassle. When pulling back and forth from both sides, how close to straight do you really think that grain is going to be? Even if you draw a line down both sides of the cloth before you start to show the distance you want to stretch to, you are still asking for trouble. You don't have a fixed point to start from.

I am not, in any way, saying that your method of the tac strips is bad, but I do not agree with pulling from both sides. You asked for an argument. I am just sharing my knowledge that stems from basic machining principles, as I am a machinist by trade. Though, I do know a little about table work as I did re-felt and re-cut the pockets on my Brunswick Gold Crown a couple of months back.

Geoff

Was curious if anyone else has been marking cloths?

I mark my cloth all the time this way I know what im doing plus it keeps the dog from peeing on my table by me marking it first he knows who owns it.

do you mark the top side or the bottom side? yes

do you mark it for length of stretch? yes

does marking the cloth for stretch achieve anything? yes

craig

OTLB

Banned

actually pulling against the warp threads side to side causes more variation for a ball rolling the length of the table and that is why I like end to end. When pulling side to side after starting the cloth it is anchored so you are not causing problems. Actually stretching cloth on the bias is what your eluding to and which by is the maximum in stretching techniques.

Trimming cloth on a table is not the smartest thing you can do. Why do it? so it looks good before you put the top on?? Glen show pics of your pockets after the table is done.

Trimming cloth like that only means that it will be a pain in the ass if the table cloth has to be used again but I know you don't care about that. If you leave overhang and want to move the table or someone sells it they can still use the same cloth over easily.

Marking cloths to determin how much stretch is enough is what I am talking about. When I put on bed cloths I don't mark anything and do it by eye and feel.

And Glen, send me one of those bed cloths and lets all see if I can put it on with my tac strips, if I can it would mean automatically that I got more stretch than you because you already trimmed it. Glen have you ever tried taking your cloth off and using it again after you trimmed it???? I always try to leave as much hanging just in case the guy sells the table or moves it.

If you take a piece of cloth, where is the greatest amount of stretch? is it at the end that your pulling to or the end that the cloth is anchored???????

Trimming cloth on a table is not the smartest thing you can do. Why do it? so it looks good before you put the top on?? Glen show pics of your pockets after the table is done.

Trimming cloth like that only means that it will be a pain in the ass if the table cloth has to be used again but I know you don't care about that. If you leave overhang and want to move the table or someone sells it they can still use the same cloth over easily.

Marking cloths to determin how much stretch is enough is what I am talking about. When I put on bed cloths I don't mark anything and do it by eye and feel.

And Glen, send me one of those bed cloths and lets all see if I can put it on with my tac strips, if I can it would mean automatically that I got more stretch than you because you already trimmed it. Glen have you ever tried taking your cloth off and using it again after you trimmed it???? I always try to leave as much hanging just in case the guy sells the table or moves it.

If you take a piece of cloth, where is the greatest amount of stretch? is it at the end that your pulling to or the end that the cloth is anchored???????

here is my pic. of course yours has staples, thats how you do the pockets. Actually the pocket area is the best for glue, the sides of the slate liners can be done over and over etc by stapling. Its the pockets that take alot of abuse from staples and adding more will only degrade the liner in that area and be the cause of problems in the future.

Your right glue should be used and in the pockets with as few a staples if any to extend the longevity or life of the table for resale value and less wear and tear on a wood substrate. As for fit and finish customer's love the french cuff, cobra flap, panty liner it looks finished and professionally done, and thats what customers want to look better then there friends or better then the last time a mechanic came out.

As for the picture if its current of your work It doesnt look right looks like it's ready for a hem and a zipper to be installed in the slate backer board.Please cut the holes out that cutting an x in the holes leads to more repair work down the road cloth or threads get caught up in the the threads of the rail bolts cause friction or a chance to strip out the inserts from cloth getting jammed into the holes from the bolt going up. this is probably the first photo of your work I didnt like most look great but this photo is awful as a finished product. Just what I see.

Craig

OTLB

Banned

Your right glue should be used and in the pockets with as few a staples if any to extend the longevity or life of the table for resale value and less wear and tear on a wood substrate. As for fit and finish customer's love the french cuff, cobra flap, panty liner it looks finished and professionally done, and thats what customers want to look better then there friends or better then the last time a mechanic came out.

As for the picture if its current of your work It doesnt look right looks like it's ready for a hem and a zipper to be installed in the slate backer board.Please cut the holes out that cutting an x in the holes leads to more repair work down the road cloth or threads get caught up in the the threads of the rail bolts cause friction or a chance to strip out the inserts from cloth getting jammed into the holes from the bolt going up. this is probably the first photo of your work I didnt like most look great but this photo is awful as a finished product. Just what I see.

Craig

Craig thats not it, fyi Threaded rod is used on a GC V and they go down through the cloth not up.

Stapling in the same place every time whith your folds will wear out the liner faster than anything. You probably add another 15 staples you don't have to. My ways looks clean and once again show pics when its done not half way as noone can see that.

If the slate doesn't have a backer then all of a sudden my way looks good. Customers may appreciate it but I see no need and I bet not many mechs spend time on this. Of course there aren't many mechs in this forum anyways so sometimes I am not sure what the hell I am doing here anyways.

Last edited:

I know that but name another table that uses threaded rod most use bolts, so what your doing is lazy not consistant from table to table no 2 or 3 customers get the same quality of work. So you save 3 minutes and are constantly trying something new with every customer. When the balls dont roll straight from an inconsistant streach you sell them a new set and tell them howe to maintain there table.

And your right there are now genuine certified mechanic's here on this forum...but there are 10-20 on here that add up to 200+ years of experince on whats good, bad, great and awful to do to a table.

I'm certified by Imperial tables, Glen and Donnie are certified/ authorized Diamond mechanics i'm working on it myself took a break from doing it as my other job i'm a contractor with all major cable companies. Last thing I want to do is climb telephone poles allday then move 300lbs slates at night .

AS matter of fact i'll be in Palm springs working for 2 months roughly on a new starter contract. Called Donn ie told him i'm in his back yard if he needs help call me i'll be close by and if not maybe we can get together for lunch and talk shop to see if there are any bugs to work out since he see's more tables and brands then I do. Show him some tools i made or use and see what he uses to.

........

And your right there are now genuine certified mechanic's here on this forum...but there are 10-20 on here that add up to 200+ years of experince on whats good, bad, great and awful to do to a table.

I'm certified by Imperial tables, Glen and Donnie are certified/ authorized Diamond mechanics i'm working on it myself took a break from doing it as my other job i'm a contractor with all major cable companies. Last thing I want to do is climb telephone poles allday then move 300lbs slates at night .

AS matter of fact i'll be in Palm springs working for 2 months roughly on a new starter contract. Called Donn ie told him i'm in his back yard if he needs help call me i'll be close by and if not maybe we can get together for lunch and talk shop to see if there are any bugs to work out since he see's more tables and brands then I do. Show him some tools i made or use and see what he uses to.

........

OTLB

Banned

I know that but name another table that uses threaded rod most use bolts, so what your doing is lazy not consistant from table to table no 2 or 3 customers get the same quality of work. So you save 3 minutes and are constantly trying something new with every customer. When the balls dont roll straight from an inconsistant streach you sell them a new set and tell them howe to maintain there table.

And your right there are now genuine certified mechanic's here on this forum...but there are 10-20 on here that add up to 200+ years of experince on whats good, bad, great and awful to do to a table.

I'm certified by Imperial tables, Glen and Donnie are certified/ authorized Diamond mechanics i'm working on it myself took a break from doing it as my other job i'm a contractor with all major cable companies. Last thing I want to do is climb telephone poles allday then move 300lbs slates at night .

AS matter of fact i'll be in Palm springs working for 2 months roughly on a new starter contract. Called Donn ie told him i'm in his back yard if he needs help call me i'll be close by and if not maybe we can get together for lunch and talk shop to see if there are any bugs to work out since he see's more tables and brands then I do. Show him some tools i made or use and see what he uses to.

........

have fun in the forum

Trimming cloth like that only means that it will be a pain in the ass if the table cloth has to be used again but I know you don't care about that. If you leave overhang and want to move the table or someone sells it they can still use the same cloth over easily.

If I know someone is going to be moving the table and want's to reuse the cloth, I straight line the cloth to the bottom of the backer board and trim there, then the cloth can be reused, otherwise I don't worry about it, as I don't worry about working in the always moving market place

Marking cloths to determin how much stretch is enough is what I am talking about. When I put on bed cloths I don't mark anything and do it by eye and feel.

You can't teach eye and feel to someone else

[/QUOTE]And Glen, send me one of those bed cloths and lets all see if I can put it on with my tac strips, if I can it would mean automatically that I got more stretch than you because you already trimmed it.[/QUOTE]

That would mean you'd be stretching the cloth another 2" plus inches to get it to attatch to your tac strips....not going to happen

[/QUOTE]Glen have you ever tried taking your cloth off and using it again after you trimmed it????[/QUOTE]

Yes, I have, and did it

[/QUOTE]If you take a piece of cloth, where is the greatest amount of stretch? is it at the end that your pulling to or the end that the cloth is anchored???????[/QUOTE]

The cloth in your hands stretching, because you have to stretch all the way through the cloth to stretch the attatched end, so it amounts to an equal stretch from point A to point B

Glen

have fun in the forum

Quiting again John? Let me tell you something John, your tack strip idea is not a new one. Long ago before I switched to using glue I had the idea of using tack strips, even tried them for a while, but they just didn't work, especially when I ran into tables that the backer boards were broken up or missing, or on bar tables that don't have any way of attaching the tack strips.

I think you miss the point of using glue to install the bed cloths, so let me point it out to you. First of all, tack strips are not marketable, whereas glue is, which means SALES! It's called royalties for the rest of my life, and with the sale of glue to install bed cloths/cushions...I can start the process of pulling mechanics together from around the world to support a system that any mechanic can install the bed cloths on ANY pool table built today...or yesterday! With the common denominator of glue, we can then start the formation of a mechanic's union so to speak, and start the process of helping to straighten out our industry...by way of communication, and advanced training...so that we ALL pull together instead of fighting against each other...and continuing the separation of mechanics.

I just spent 3 days with a mechanic by the name of Jack Zimmerman from out of the Indianapolis area that drove 4 hours out to the Chicago area just to learn from me...AND paid him $500 for the help he provided...on 3 Gold Crown 4's!!!! Now, what have YOU done lately to try and work with another mechanic to pass on YOUR knowledge? Jack was just blown away with what he saw and learned, and before he even left to go back home, he bought the same glue tray and 3" roller that I use because HE is going to start installing the bed cloths with glue instead of staples...or tack strips!

Why you ask?...Because it's a better system, that's why. And to top it off, he couldn't believe how tight HE could install the Granito 2000 tournament cloth...stretching it 4" side to side, and he learned how to finish the side pockets without having to fight the pocket flaps to get it done right...and yes, he learned how to do the RKC pocket folds

The one thing I see most about you John....is you're all about me, me, me...and I, I , I, as there is no US in your game plan! Keep up the good work John, and I have never said you did bad work...I just don't see your work setting you apart from anyone else's work that I've seen over the last 26 years

Glen

Helpful

Thanks, Ron

Good Job, Glen. I am sorry we did not hook up.As you know when we talked. I will not be doing tables for a while. The economy has forced me to take a new direction. I have always admired you and have learned a lot from you. I will continue to read post and stay in the billiard world. I hope you can get more mechanics to start using your method. That way when the economy pics up and i start doing table work again, My job should be easier.:thumbup::thumbup::thumbup:Quiting again John? Let me tell you something John, your tack strip idea is not a new one. Long ago before I switched to using glue I had the idea of using tack strips, even tried them for a while, but they just didn't work, especially when I ran into tables that the backer boards were broken up or missing, or on bar tables that don't have any way of attaching the tack strips.

I think you miss the point of using glue to install the bed cloths, so let me point it out to you. First of all, tack strips are not marketable, whereas glue is, which means SALES! It's called royalties for the rest of my life, and with the sale of glue to install bed cloths/cushions...I can start the process of pulling mechanics together from around the world to support a system that any mechanic can install the bed cloths on ANY pool table built today...or yesterday! With the common denominator of glue, we can then start the formation of a mechanic's union so to speak, and start the process of helping to straighten out our industry...by way of communication, and advanced training...so that we ALL pull together instead of fighting against each other...and continuing the separation of mechanics.

I just spent 3 days with a mechanic by the name of Jack Zimmerman from out of the Indianapolis area that drove 4 hours out to the Chicago area just to learn from me...AND paid him $500 for the help he provided...on 3 Gold Crown 4's!!!! Now, what have YOU done lately to try and work with another mechanic to pass on YOUR knowledge? Jack was just blown away with what he saw and learned, and before he even left to go back home, he bought the same glue tray and 3" roller that I use because HE is going to start installing the bed cloths with glue instead of staples...or tack strips!

Why you ask?...Because it's a better system, that's why. And to top it off, he couldn't believe how tight HE could install the Granito 2000 tournament cloth...stretching it 4" side to side, and he learned how to finish the side pockets without having to fight the pocket flaps to get it done right...and yes, he learned how to do the RKC pocket folds

The one thing I see most about you John....is you're all about me, me, me...and I, I , I, as there is no US in your game plan! Keep up the good work John, and I have never said you did bad work...I just don't see your work setting you apart from anyone else's work that I've seen over the last 26 years

Glen

Thanks, Ron