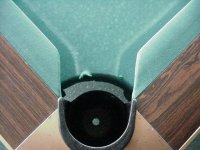

I am talking about the slate covering at the pocket openings close to the slate radius.Are you talking about the slate pocket of the tables? Because that all depends on what kind of tables you're talking about. Or, are you talking about inside the pockets on the facings of the rails? If this is the case, that happens because the facings are either worn out, or 1/8" thick. If the facings were 3/16" neoprene to begin with, that would never happen.

Glen

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simonis Std Green 860 -- their website Fails so I ask the experts

- Thread starter OTLB

- Start date

How long has the cloth been on the tables?

I had noticed in in a place that used Mali coth and I would say it was on for a while... don't know exactly. And a friend of mine tells me two tables at his club were covereed recently in 860 blue and it is happening ther as well. couild it be misuse?

And these are drop pocket tables?

yes sir.drop pockets

OTLB

Banned

as pockets fill up with balls people move them from side to side. They often hammer them in the other pocket and when they do they drop them on against the slate. Also hands wear when they go into the pocket at the edge especially if they have on rings and perhaps a watch. It can also be sharp slate but usually you see this on drop pocket tables. IMO

Last edited:

as pockets fill up with balls people move them from side to side. They often hammer them in the other pocket and when they do they drop them on against the slate. Also hands wear when they go into the pocket at the edge especially if they have on rings and perhaps a watch. It can also be sharp slate but usually you see this on drop pocket tables. IMO

The most recently covered table with the 860 has a lot of one pocket play and the others, just a lot of play.

OTLB

Banned

the greatest amount of stretch occurs near all the sides, including the pockets. This is an issue on drop pocket tables IMO where people rub, scrap, drop balls etc. Does anyone ever see this on ball return tables? I haven't except perhaps if a glue line was left and not properly cleaned off the edge of the slate. So maybe there is more merit to ball return models for this reason. But IMO the cloth should probably been changed before that happens. If pool was like golf many rooms wouldn't have any business because of lack of upkeep. I would never play golf at a course that wasn't maintained but pool rooms seem to get away with it. IMO pool rooms should not replace all the cloth at once but do them in stages for this reason. At least they would have some good tables to play on.

Would also say it occurs more on the side that the cloth is pulled to last, which again IMO causes excessive wear in the ball trough area.

Would also say it occurs more on the side that the cloth is pulled to last, which again IMO causes excessive wear in the ball trough area.

Last edited:

Awwww come on guys, this is NOT a problem on Diamond or Brunswick GC's as they have deeper backs to the pockets...and backing on the slates. When things like this happen, it happens because the manufacture of the tables didn't take into consideration the room needed in the back of the pockets to keep the balls from slamming back into the slate edge when the balls are being pocketed. It has NOTHING to do with reaching your hands into the pockets, nor dropping balls into other pockets to remove some of the overflow of one pocket. Ball returns on some of these tables we're talking about afford the balls to drop deeper into the pockets so as to stop some of the cloth cutting....but come on guys...WHAT kind of tables are we talking about here???? Not ALL tables are built the same!!!

Glen

Glen

Stretching from 1 side to the other -

This is the cloth I mentioned to you Glen.

Hey I know that place, got my A## handed to me there last week by Duane....

place

Duane Tuula, Is a great player and do not feel bad. I have had my ass kicked around by him, plenty. LOL That maybe be why he is a master. He is a great guy and pool player. I can not say enough about him. He has helped the pool community out in the Rockford area , ALOT. Thanks, Ron

Duane Tuula, Is a great player and do not feel bad. I have had my ass kicked around by him, plenty. LOL That maybe be why he is a master. He is a great guy and pool player. I can not say enough about him. He has helped the pool community out in the Rockford area , ALOT. Thanks, Ron

Awwww come on guys, this is NOT a problem on Diamond or Brunswick GC's as they have deeper backs to the pockets...and backing on the slates. When things like this happen, it happens because the manufacture of the tables didn't take into consideration the room needed in the back of the pockets to keep the balls from slamming back into the slate edge when the balls are being pocketed. It has NOTHING to do with reaching your hands into the pockets, nor dropping balls into other pockets to remove some of the overflow of one pocket. Ball returns on some of these tables we're talking about afford the balls to drop deeper into the pockets so as to stop some of the cloth cutting....but come on guys...WHAT kind of tables are we talking about here???? Not ALL tables are built the same!!!

Glen

Tables with the Mali are Gandys and the table with the 860 is a Brunswick GC3. I think some of the wear is from abuse and a combination of all the other reasons given here. I have seen pocket facings on the Gandy wear holes the size of nickels in the cloth too. Any kind of friction will cause wear and I think loose cloth causes more friction too as well as worn out balls.

OTLB

Banned

Tables with the Mali are Gandys and the table with the 860 is a Brunswick GC3. I think some of the wear is from abuse and a combination of all the other reasons given here. I have seen pocket facings on the Gandy wear holes the size of nickels in the cloth too. Any kind of friction will cause wear and I think loose cloth causes more friction too as well as worn out balls.

Again IMO this is mostly wear, abuse etc and cloth should be replaced. Hole starting on right where the ball does NOT hit also. Is this what you mean Majic? Haven't seen this on GC's fitted with new GC IV-V drop pockets though.

Attachments

Last edited:

yes.......thats itAgain IMO this is mostly wear, abouse etc and cloth should be replaced. Hole starting on right where the ball does NOT hit. Is this what you mean Magic

OTLB

Banned

Well, it seems that noone has been doing their homework. Instead of marking cloths just measure how much cloth you have left on the edges of the slate. Example, slate is 57 wide, plus 2 for the thickness of the slate. You started with say 60. How much is left below the slate on both sides?

We should establish the specs for how tight it goes down. What is the min and max.

I have found that gathering data from cloths already on tables to be unreliable for this research.

We should establish the specs for how tight it goes down. What is the min and max.

I have found that gathering data from cloths already on tables to be unreliable for this research.

Well, it seems that noone has been doing their homework. Instead of marking cloths just measure how much cloth you have left on the edges of the slate. Example, slate is 57 wide, plus 2 for the thickness of the slate. You started with say 60. How much is left below the slate on both sides?

We should establish the specs for how tight it goes down. What is the min and max.

I have found that gathering data from cloths already on tables to be unreliable for this research.

Nice thought, but that's like driving a car backwards in order to get where you're going

OTLB

Banned

sometimes the only way to see where your going is to go backwards first. This is an easy way to see how much stretch you have. It is easy to figure it this way. 57 + 2 for the pull down of the slate. example: you start with 60-59 for slate and then theres 5 inches leftover below the slate when you add the two sides together. 4 inch stretch.

Interestingly to me would be the scenario of knowing what a given mechs stretch was before and then comparing it to my tac strip method with the same guy. Regardless though I would love to hear arguments why stetching cloth from both sides with my tac strip method is not as good as pulling cloth from only one side.

Interestingly to me would be the scenario of knowing what a given mechs stretch was before and then comparing it to my tac strip method with the same guy. Regardless though I would love to hear arguments why stetching cloth from both sides with my tac strip method is not as good as pulling cloth from only one side.

Last edited:

sometimes the only way to see where your going is to go backwards first. This is an easy way to see how much stretch you have. It is easy to figure it this way. 57 + 2 for the pull down of the slate. example: you start with 60-59 for slate and then theres 5 inches leftover below the slate when you add the two sides together. 4 inch stretch.

Interestingly to me would be the scenario of knowing what a given mechs stretch was before and then comparing it to my tac strip method with the same guy. Regardless though I would love to hear arguments why stetching cloth from both sides with my tac strip method is not as good as pulling cloth from only one side.

I just finished installing some 760 on a Diamond 7ft bar box, marked the stretch at 2" before I installed it, installed the cloth and stetched it the 2" I marked out for the stretch....now why would I measure the cut off to find out how much I stretched the cloth

Glen