I edited diagram 2...

I edited diagram 2 to do just what you describe; I just cut and pasted the screw part of the diagram.....

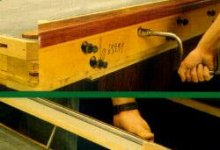

Fig 3 (as you depicted) allows room for a screw up thru the liner/slate into the subrails.

You could do the same in Fig 2 using a much longer screw up thru the frame/liner/slate into the subrail.

If the horizontal rail bolts and anchors are in good shape the rails should play as originally designed

without a need for extra screws. JMO

I edited diagram 2 to do just what you describe; I just cut and pasted the screw part of the diagram.....