The building will be going up soon and it is time to draw up the inside. My shop is going to be 36' x48' and I got a 36' porch on the front so it doesnt look like a garage. I will have a bathroom and kitchenette in it and a 12x36 space that will be a showroom. But anyone have any ideas for the shop. I would like to have airlines and dust collection at each of my work stations but have not had time for the research of it yet. I hope to have everything moved over and up and running before thanksgiving.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What do I need in my new workshop.

- Thread starter jecues

- Start date

what all equipment do you have? and if you subtract the showroom the shop is going to be 24x12???? what all will you have in a show room that big? pool tables?

If I understand right his shop space sill be 36x36 unless the porch is included in the square footage. But you are right that we need to know what he already has in order not to re-invent the wheel when making suggestions on what to get.

Maybe start out with a Redhead , alway good to have " shop helper ".

Boobies!

Somehow I almost knew you would say that Jim.

Somehow I almost knew you would say that Jim.

Rockler has a good selection of dust collection systems... http://www.rockler.com/search_results.cfm?srch=usr&filter=dust&submit.x=13&submit.y=9

The shop size is 36'x36 I have been building cues for about 2 years with great luck in my area with about 45 cues out know I built my stock up for 2 years before building my first cue. I have a dlx cue smith a stand alone inlay machine and in the next couple of days I will have my grizzly milling machine with power feed plus all of the standard wood working tools needed drill press bandsaw plainer router belt sander I am looking for something that cuemakers have developed for there shop or something they wish they did. I have heated concrete floors and air conditioning and that is about all I have got for the shop

If you don't have a metal lathe, I suggest getting one.

The shop size is 36'x36 I have been building cues for about 2 years with great luck in my area with about 45 cues out know I built my stock up for 2 years before building my first cue. I have a dlx cue smith a stand alone inlay machine and in the next couple of days I will have my grizzly milling machine with power feed plus all of the standard wood working tools needed drill press bandsaw plainer router belt sander I am looking for something that cuemakers have developed for there shop or something they wish they did. I have heated concrete floors and air conditioning and that is about all I have got for the shop

Git! GIT, GIT, GIT.

I have the option of coat or no-coat. :thumbup:

Add an attached closet to the outside, or wall up a closet inside the shop in a corner that is vented to the outside as it is best to put your dust collector "outside" of the shop. This will reduce noise in the shop, create more space inside, and improve the air quality in the shop. I recommend a good cyclone dust collector. While you are at it, you can put your shop compressor in the same place for more noise reduction. Then you can get a hanging air filter for the inside of the shop.

Kelly

Kelly

well you can mount your dust collector out side to save room or in a corner, if your going to spary find a corner and build a small room for spraying.

also ive found that if you have the space put your lathes back to back in the middle of the room makes it esy to go from operation to operation after all the lathes and inlay machine are put in the middle then line the walls on the out side with work benches for saws sanders and whatever else. and keep wood storage the benches and hang wood in progress above the benches.

you will have plenty of room to work with and i would second the metal lathe option.

also ive found that if you have the space put your lathes back to back in the middle of the room makes it esy to go from operation to operation after all the lathes and inlay machine are put in the middle then line the walls on the out side with work benches for saws sanders and whatever else. and keep wood storage the benches and hang wood in progress above the benches.

you will have plenty of room to work with and i would second the metal lathe option.

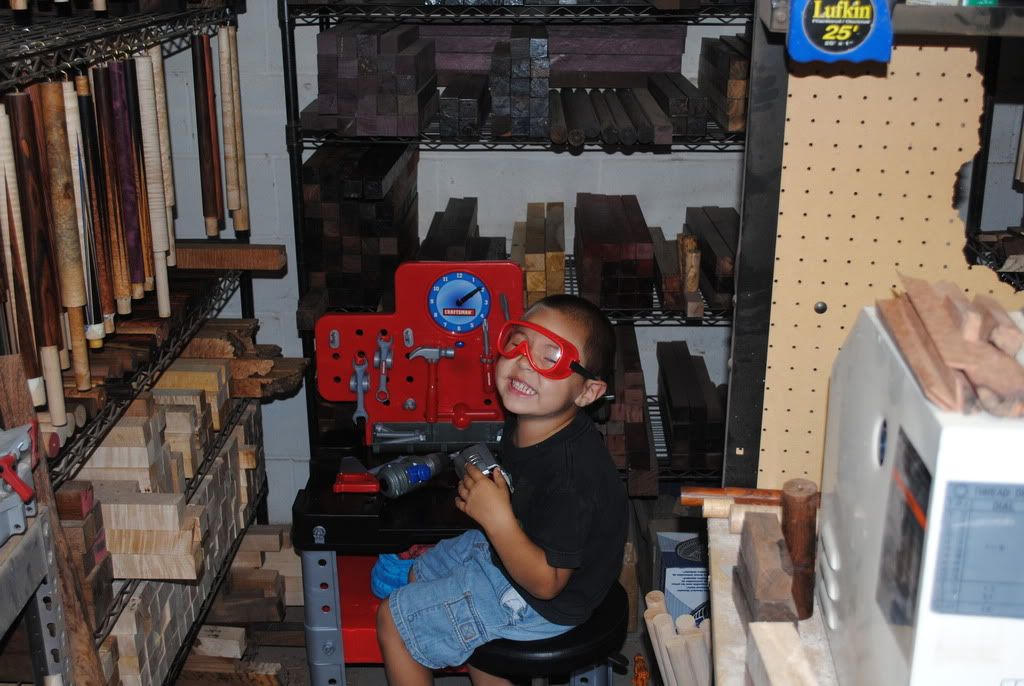

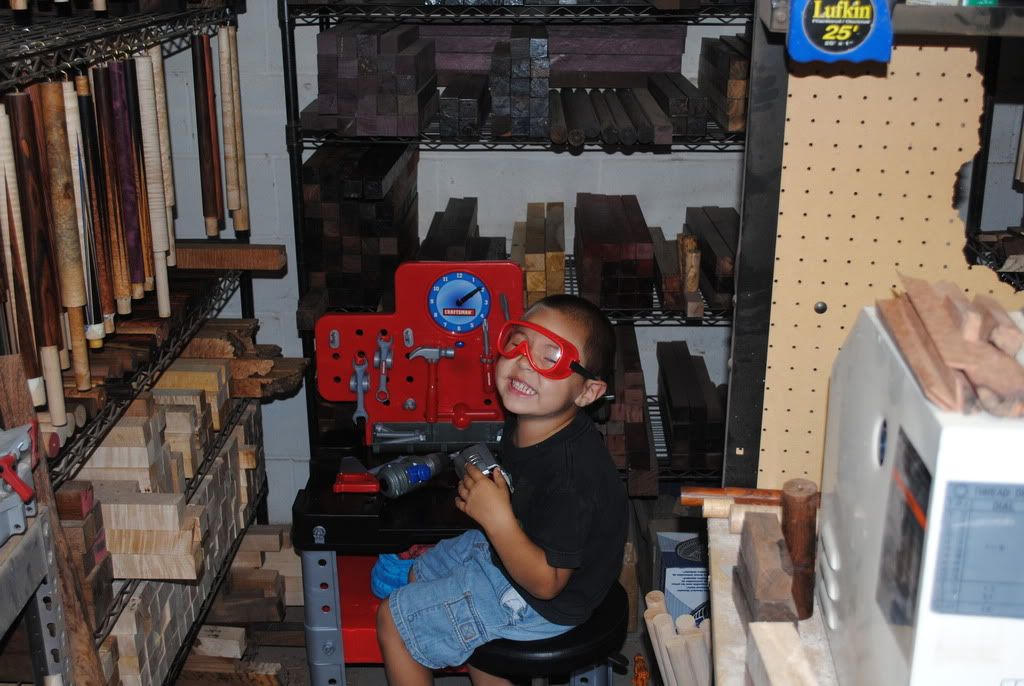

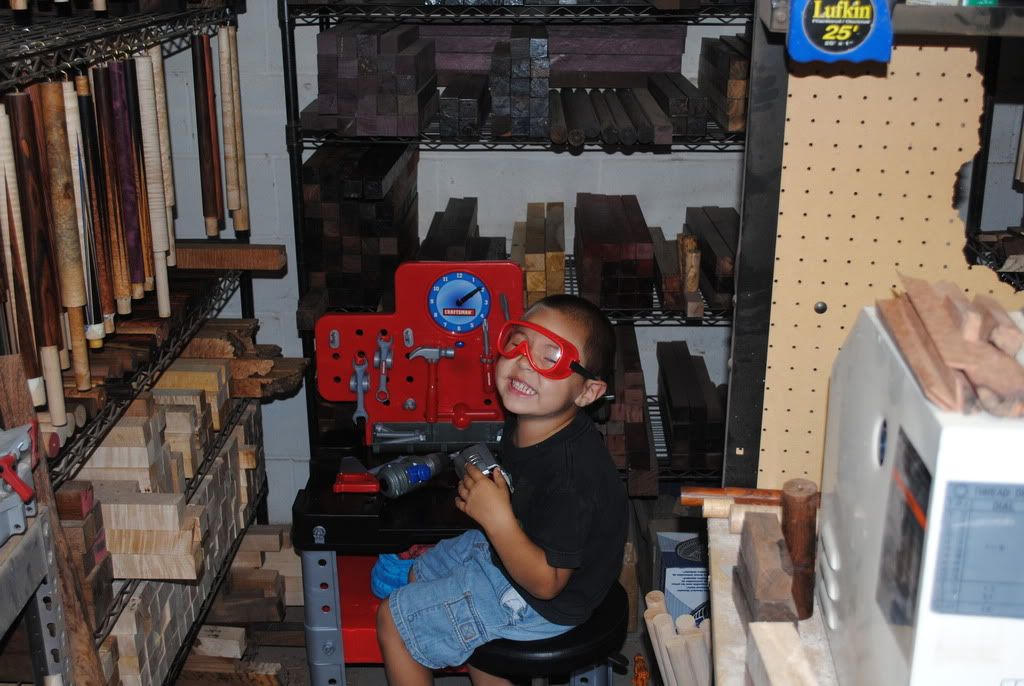

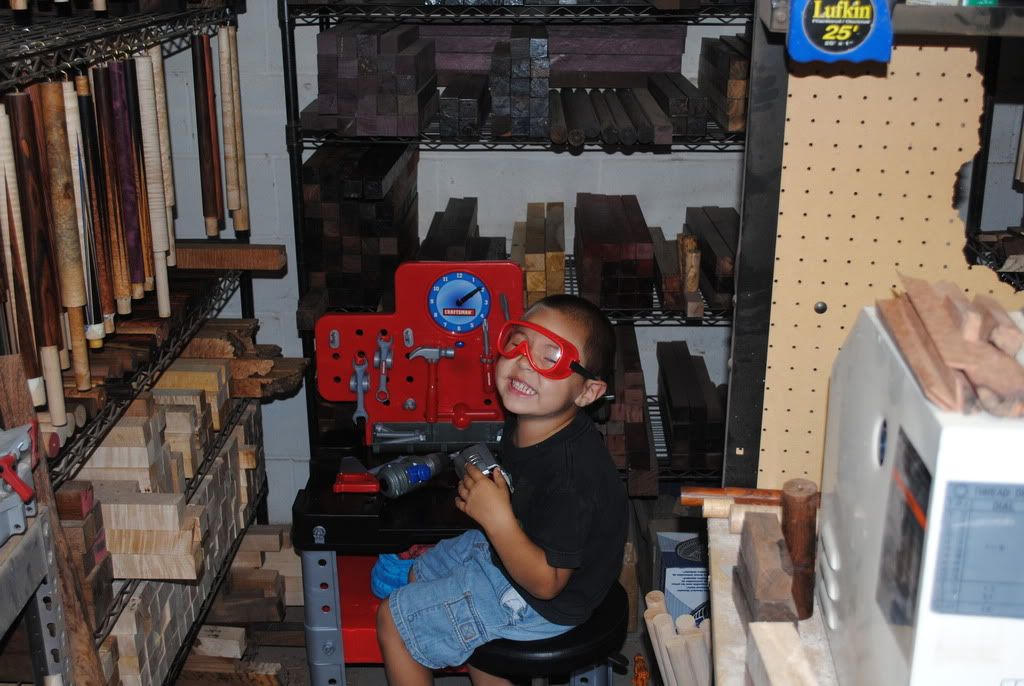

Nothing is more important in my shop than rubber mats that lay in front of my machines. It's much easier standing on those than it is concrete. As for benches, Sam's Club has some awesome benches for pretty cheap. I have several of them. Great for desktop equipment. I store my squares of wood on metal rack shelves from the hardware store. You can adjust the shelves to whatever height is best for you. I use the same thing for hanging shafts, except have about 36" between the shelves. Works out great & is cheap, plus looks good. Having organized wood storage is paramount. Here's a pic of my shop helper at his bench, and you can see a couple of my wood racks:

Nothing is more important in my shop than rubber mats that lay in front of my machines. It's much easier standing on those than it is concrete. As for benches, Sam's Club has some awesome benches for pretty cheap. I have several of them. Great for desktop equipment. I store my squares of wood on metal rack shelves from the hardware store. You can adjust the shelves to whatever height is best for you. I use the same thing for hanging shafts, except have about 36" between the shelves. Works out great & is cheap, plus looks good. Having organized wood storage is paramount. Here's a pic of my shop helper at his bench, and you can see a couple of my wood racks:

Show off

Nothing is more important in my shop than rubber mats that lay in front of my machines. It's much easier standing on those than it is concrete. As for benches, Sam's Club has some awesome benches for pretty cheap. I have several of them. Great for desktop equipment. I store my squares of wood on metal rack shelves from the hardware store. You can adjust the shelves to whatever height is best for you. I use the same thing for hanging shafts, except have about 36" between the shelves. Works out great & is cheap, plus looks good. Having organized wood storage is paramount. Here's a pic of my shop helper at his bench, and you can see a couple of my wood racks:

Eric,

I think I see a future generation cue maker in the making!!

Rick

Last edited:

Eric,

I thinks I see a future generation cue maker in the making!!

Rick

Not until he gets an education & successful career first!!!! Then if he has time to tinker, i'll let him in the shop :thumbup:

If you are thinking long term I would address some of the things which are hard to change later. First you have to decide on your approach to wood storage. Are you going to let your stock fluctuate with ups and downs of the relative humidity or are you going to try and keep a constant humidity level. So in other words keep the whole shop regulated or build a room to house all the wood in progress. Then I would devide your space into working areas the rough milling of wood makes alot of mess and is not as easily contained so having a seperate area for that is a good idea. Then I would decide if its going to be a one man shop or not. If its only you, you can configure your machines in such a way that you can operate more than one piece at a time as well as save room. Dust controle, air lines and power outlets are easiet done fisrt but knowing wher your equipment is going has to be established. Take some time and think out your order of operations, from getting material in the shop to steps in processing said material to storage etc etc. Its alot like designing a good kitchen it all revolves around how you work and making it as efficient as you can. And lastly plan on futer equipment that will come later. I would change alot about my shop if I new then what I know now but that is always the case. Just a few thoughts

Last edited:

I'm of the belief that a pool table is necessary in a cue shop. You need some place to test hit cues, roll shafts, butts and complete cues and keep your repair customers out of your hair while you're working on their cues.

Sherm

Hi,

Sherm makes a great point, a pool table is a must if you have the room. You must have a level surface to roll your cues and if a customer comes to your shop to buy a cue they can hit balls with their new cue.

I was lucky to pick up a 1957 6' valley bar box and we built a framed removable table top that we also use as a work and assembly table with handles. I can move the table over about 16" to roll a cue real fast without taking the top off completely. Real convenient. I plan to put a rigging system with a winch to raise it up and down and install lights under the table for playing pool and for photographing cues.

Shop floor space is always at a premium and whenever you can, utilize vertical space. Look for used kitchen cabinets and fill your walls with them,

Rick G

Pool Table with Assembly Table Top

Handles on each end for moving

Utilize vertical space whenever you can