Look people, if you're in the market to buy a used GC of any model, make sure you know what you're getting yourself into first. Ask questions, like who worked on it last...do you have his phone number so I can ask him about the table you're offering for sale?

Do you know much about the table you're offering for sale?

I'm going to give all of you some questions to ask of anyone selling a Diamond or Gold Crown that you can ask first...and get answers to...before you pull the trigger on buying a pool table....so maybe you'll avoid what happened to Kyle....when he bought a GC1/2/3....made up of all different GC parts, including the slates....2 head end unmatching slates, and a center slate out of some other set of slates...different thicknesses and all. This is what $1,000 bought...sight unseen, but swarn to be in great shape...GC3!

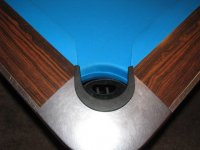

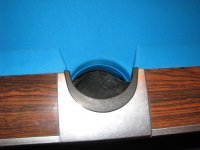

Lets start with what the slates looked like when I got to the location to pick up this table:grin:

Do you know much about the table you're offering for sale?

I'm going to give all of you some questions to ask of anyone selling a Diamond or Gold Crown that you can ask first...and get answers to...before you pull the trigger on buying a pool table....so maybe you'll avoid what happened to Kyle....when he bought a GC1/2/3....made up of all different GC parts, including the slates....2 head end unmatching slates, and a center slate out of some other set of slates...different thicknesses and all. This is what $1,000 bought...sight unseen, but swarn to be in great shape...GC3!

Lets start with what the slates looked like when I got to the location to pick up this table:grin: