Is this your lathe?

That is curious and almost funny that the spindle ends in a bolt on flange.

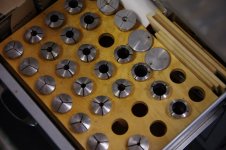

That said, I can’t see any reason to not use it. You can modify any plain back chuck to fit, or an appropriate side A- taper back chuck. You can also fit a A- taper large series Jacobs rubberflex or Sjogren collet chuck to it.

Putting a plain back 4 jaw would get you in business with virtually no extra work or mods except possibly adding a few screw holes to the flange

With that much flange, I imagine it would be possible, possibly to make said chucks, collet chucks, etc “adjustrue” With a little extra effort.

nothing I can find indicates the actual nose projection.

However with that info, you could determine whether reducing the flange and threading it 2-1/4 -8 (as example) or other thread or taper for common spindle accessories is viable.

It seems highly unlikely that precision bearings are used in such lathes, so keeping the option for adjustru feature might not be imprudent. Then again, what class spindle bearings do cue lathes use, either. Or hang a 4 jaw on it & get to work.

Since you mention wanting to get out from under it; at the right price (stealing

or cash plus wood) I could possibly be interested in taking a look if you don’t want to do the work to make it useful.

smt

ps, re: 6 jaw chucks: theory seems to be they will hold with less pressure.

Maybe, maybe not. In metalworking it is understood that a “good” 6 jaw chuck only bears on 3 or 4 jaws unless a the part is perfectly round. A less than “good” example, what is the point. They are good for compliant materials and thin tubes. But AFA whether they will mar less holding wood, there is always the factor of actually gripping on 3 or 4 jaws, or having 1 high jaw actually more likely to mark.

Nonetheless, people do have different experiences and preferences, some in contradiction to what geometry or logic might seem to predict. In cue work if you don’t have large collets, 6jaws is useful to hold rings and tubes with less possibility of collapse. When boring rings & such the released part will be more round (if the OD was originally) than from a 3jaw which might yield a lobed part on thin material. For the same reason I prefer to bore in a collet.