At OB Cues, we still use Auto Clear on our cue shafts, but I have been playing around with UV since we started to build the Break Cues.

I too have found it a little harder to buff out, but there are answers for that.

For those that run into cracking, I think there is an important aspect to UV clears that is often overlooked. You must use an "insulator" or primer of some sort that is NOT a UV cured product. Think about it. The UV products are cured by the UV light. That light cannot penetrate into the wood, so the finish that soaks into the wood never cures. The Insulator products provide a surface that the UV will attache to, and will allow it to fully cure. I think this could be causing the cracking issues some have seen.

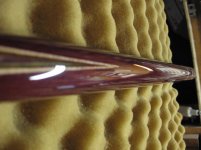

Right now I am in the middle of working out the right buffing procedures. Once I have it down, I will share it on here. Basically, I believe that i will be able to wet sand to 1500, and then buff in 2 steps and have zero scratches left (under magnification) and that "wet" look we all strive for. I've seen many cues with this look that were finished with UV so I know it can be done. I just want to get it down to as few steps as possible. I think we over do it with sanding. Buffing can do amazing things when you get the right compounds and the right speeds.