It's a moot point as I did not realize there was a sprocket with this ball polisher.If the platter was centered under the balls, each perimeter "ring" of balls would be getting the exact same constant motion and speed from the platter and they would have a tendency to want to spin on one axis. Because each distance from the center of the platter is rotating at a different speed (one inch from the outside edge of the platter is spinning a whole lot faster than one inch from the center of the platter is spinning), when the platter is offset to the balls this allows for the effective direction and speed of the platter to change in relation to any particular ball location and as the sprocket rotates the balls around its 360 degrees this causes every ball to be rotated around all axes.

Put more succinctly, as the sprocket rotates around this allows each of the balls to constantly encounter a different part of the platter that is going a slightly different speed/direction because of the platter offset which in turn causes the balls to be rotated about all their axes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"Gold Crown" Ball Polisher

- Thread starter rexus31

- Start date

Being at an angle wouldn't change the centrifical force of the balls spinning.

But it would change the pressure of the balls against the walls and the sprocket.

Think of the carnival ride where you’re standing and it starts spinning and then slowly rises up on an angle.

When it starts to spin you’re pressed up against the walls and when it starts to rise you can really feel more pressure on the down rotation.

Hmmm, I have me an idea.

And yet you're still stuck to the wall at your back because of centrifical force. If that same ride spun fast enough if could stand straight up and down, and you'd still be pressed with your back against the wall.But it would change the pressure of the balls against the walls and the sprocket.

Think of the carnival ride where you’re standing and it starts spinning and then slowly rises up on an angle.

When it starts to spin you’re pressed up against the walls and when it starts to rise you can really feel more pressure on the down rotation.

Hmmm, I have me an idea.

And yet you're still stuck to the wall at your back because of centrifical force. If that same ride spun fast enough if could stand straight up and down, and you'd still be pressed with your back against the wall.

I’d have to show you what I’m getting at.

My next design is going to put every ball polisher ever built in the past to shameI’d have to show you what I’m getting at.

Not if I beat you to it.My next design is going to put every ball polisher ever built in the past to shame

Do it, but pack a lunch, you're going to be at it a whileNot if I beat you to it.

The race is on pimp!Do it, but pack a lunch, you're going to be at it a while

Good luck to ya

I think RKC has got a bit of a head start...LOL!!!The race is on pimp!

Good luck to ya

The tortise has won races before.I think RKC has got a bit of a head start...LOL!!!

You do know alligators eat tortoises rightThe tortise has won races before.

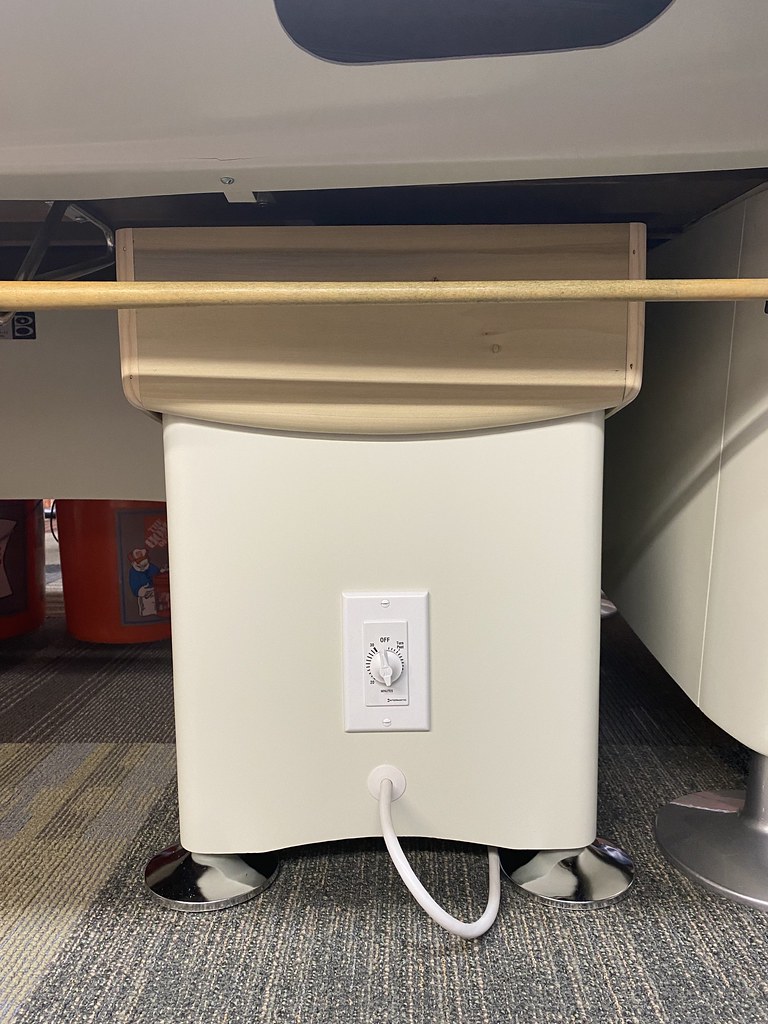

I will say this is probably the last time I build something from scrap wood that I intend to have a nice finish. Many hours of priming and blocking finally led me to a surface suitable for paint.

All the hard work paid off. I sprayed the first coat of the Brunswick White Sherwin Williams Emerald Enamel today with my Graco TC Pro Airless and it came out fantastic. Second coat tomorrow.

Before final prime, I decided to go with Stafast 1/4-20 Hardwood Threaded Inserts for the feet.

All the hard work paid off. I sprayed the first coat of the Brunswick White Sherwin Williams Emerald Enamel today with my Graco TC Pro Airless and it came out fantastic. Second coat tomorrow.

Before final prime, I decided to go with Stafast 1/4-20 Hardwood Threaded Inserts for the feet.

Last edited:

That is a beautiful piece of work. A true custom. The time that went into it.. the meticulous finish shows. Seriously nice craftsmanship.Many hours of priming and blocking finally led me to a surface suitable for paint.

All the hard work paid off. I sprayed the first coat of the Brunswick White Sherwin Williams Emerald Enamel today with my Graco TC Pro Airless and it came out fantastic. Second coat tomorrow.

Before final prime, I decided to go with Stafast 1/4-20 Hardwood Threaded Inserts for the feet.

Last edited:

What an awesome ball polisher. The only thing that would bother me, and it would drive me absolutely nuts to the point that I would have to correct it, is the electrical cord coming out of the front of the unit instead of the back. I know, minor stuff in the scheme of things.

Thanks. I suppose it comes down to what you consider the back. Being as the only side with anything on it is the side with the switch, I consider it the “back”. Plus, better to only have one side with things coming out of it than two. It’s cleaner that way, IMO.What an awesome ball polisher. The only thing that would bother me, and it would drive me absolutely nuts to the point that I would have to correct it, is the electrical cord coming out of the front of the unit instead of the back. I know, minor stuff in the scheme of things.

The side that will always be facing out and that has the operating controls, which will be the side with the timer, is indisputably the front.Thanks. I suppose it comes down to what you consider the back. Being as the only side with anything on it is the side with the switch, I consider it the “back”.

It's cleaner when the cord comes out the back so you don't have to look at it, which is why literally everything on earth that has an electrical cord has it coming out the back unless there is a functional reason that can't be possible. To each their own though, and the only guy whose happiness matters in this case is yours. While that would personally drive me nuts, in some sense it is minor and your polisher is otherwise gorgeous and you did a great job.Plus, better to only have one side with things coming out of it than two. It’s cleaner that way, IMO.

I really only mentioned it in the off chance you hadn't realized it and it will end up driving you nuts too, because right now it could still be corrected before it is too late if you were so inclined, but very shortly that will no longer be very feasible. Sounds like whether you were aware of before now or not, it doesn't bother you and that's all that matters.

Last edited:

Valid points.The side that will always be facing out and that has the operating controls, which will be the side with the timer, is indisputably the front.

It's cleaner when the cord comes out the back so you don't have to look at it, which is why literally everything on earth that has an electrical cord has it coming out the back unless there is a functional reason that can't be possible. To each their own though, and the only guy whose happiness matters in this case is yours. While that would personally drive me nuts, in some sense it is minor and your polisher is otherwise gorgeous and you did a great job.

It is the way it is by design. The motor is mounted on the interior of opposite wall so exiting the cord there was not an option.I really only mentioned it in the off chance you hadn't realized it and it will end up driving you nuts too, because right now it could still be corrected before it is too late if you were so inclined, but very shortly that will no longer be very feasible. Sounds like whether you were aware of before now or not, it doesn't bother you and that's all that matters.

tomatoshooter

Well-known member

The label is a nice touch.

Thanks. The devil is in the details.The label is a nice touch.